Chapter 3 Error Correction

3-10

3. 1. 4 J-0106 / 0206 Fuser section

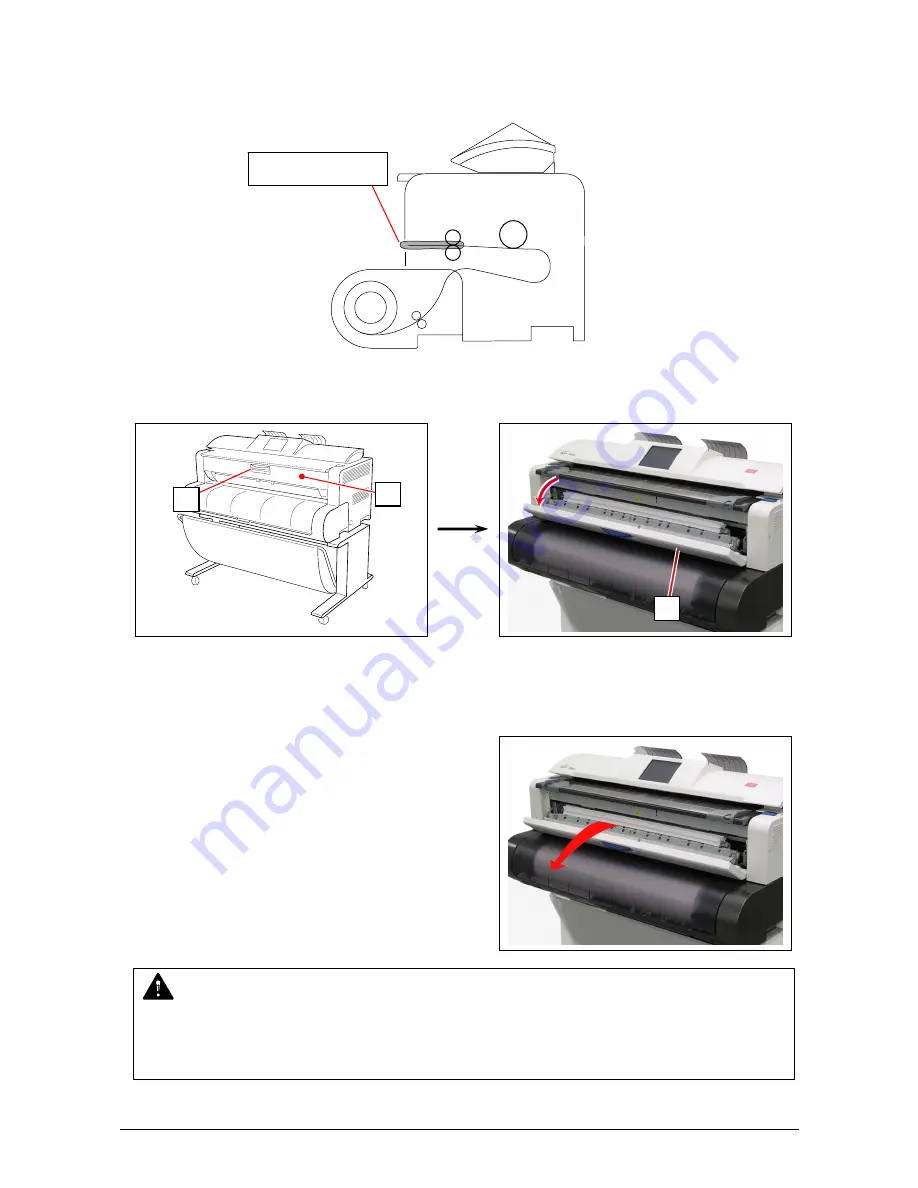

Remove a mis-feed media in the Fuser section if the UI screen will show J-0106 or 0206.

1. Hold the blue handle (1) and open the Exit Cover (2).

2. If it is possible, pull and remove the mis-feed media.

If little amount of the leading edge area is coming to the Fuser and you cannot pull it out,

or if the trailing edge remains deep to be caught in the printer, do not pull it by force.

Leave it there and go to the next step.

J-0106 or J-0206

WARNING

There are extremely hot parts inside the Fuser Unit. Do not touch any parts in the Fuser Unit,

or you will be burnt.

Also the mis-fed media can be very hot. Be careful not to get burnt when you remove it.

1

2

2