ASSEMBLY

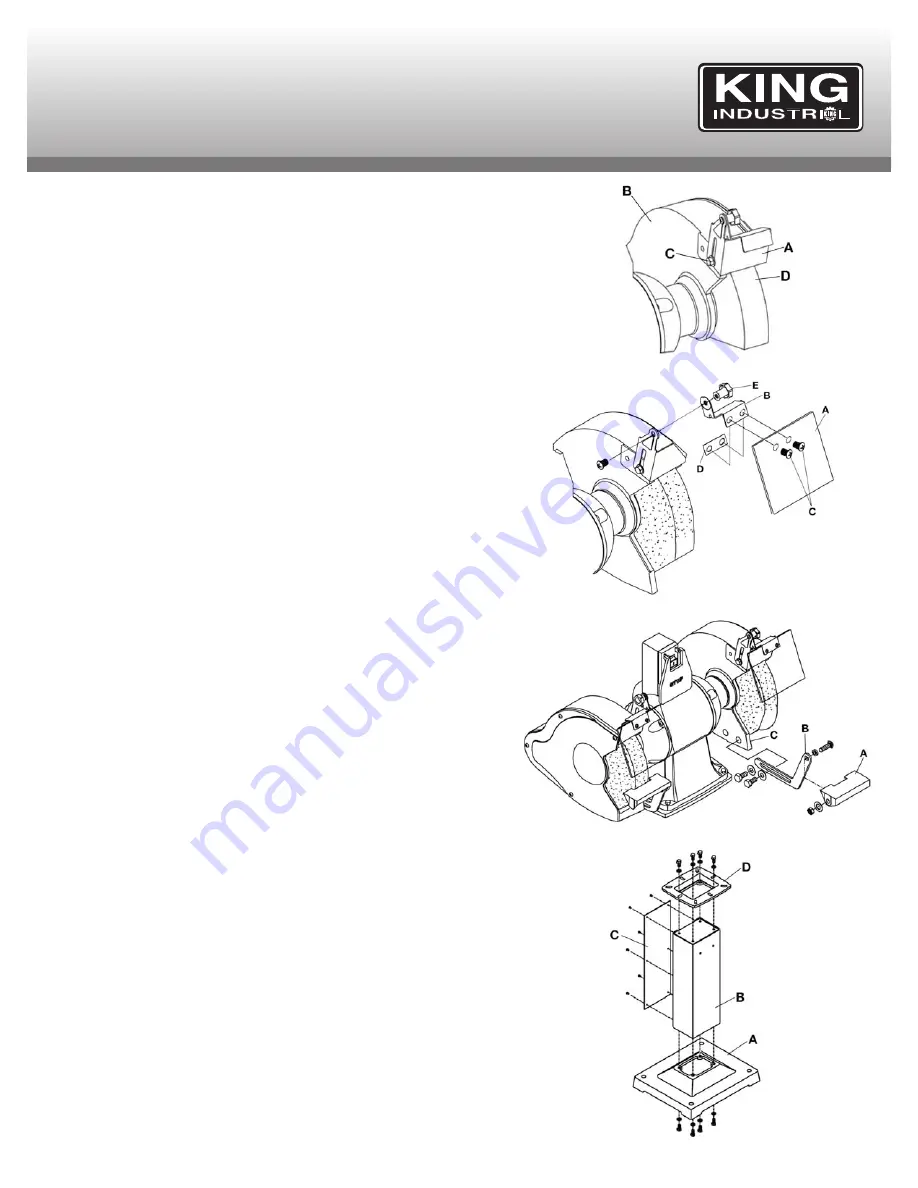

Installing spark guards to wheel guards

1. Install the spark guard (A) Fig.4 to the inside surface of the wheel guard

(B) using a washer and hex. bolt (C). Repeat for the other side.

2. Adjust both spark guards (A) until they are 1/16” from the grinding wheels

(D). Firmly tighten the hex. bolts (C).

Installing eye shields to spark guards

1. Attach the eye shield (A) Fig.5 to the eye shield pivot support (B) by

inserting pan head screws (C) through the eye shield and the pivot

support, then screw them into the back plate (D). Repeat for other side.

2. Secure the eye shield pivot support angle by tightening the lock knob (E)

Fig.5.

Installing tool rests to wheel guards

1. Attach the tool rest (A) Fig.6 to the tool rest support (B) using a carriage

bolt, flat ring, washer and hex. nut.

2. Attach the tool rest support (B) to the wheel guard (C) using two hex.

bolts and washers.

3. Adjust the tool rests until they are 1/16” from the grinding wheel. Firmly

tighten the hex. bolts holding the tool rest support. Repeat for other side.

Assembling stand

1. Assemble the base (A) Fig.7 and the leg (B) together using four hex. bolts

and washers.

2. Install the back cover (C) onto the leg (B) using six pan head screws.

3. Assemble the top support (D) onto the leg (B) with four hex. bolts and

spring washers.

FIGURE 4

FIGURE 5

FIGURE 6

FIGURE 7