TK-3202L

16

ADJUSTMENT

Test Equipment Required for Alignment

Test Equipment

Major Specifications

1.

Standard Signal Generator

Frequency Range

450 to 490MHz (K, M) 470 to 512MHz (K2, M2)

(SSG)

400 to 430MHz (K3)

Modulation

Frequency modulation and external modulation

Output

-127dBm/0.1µV to greater than -47dBm/1mV

2.

Power Meter

Input Impedance

50

Ω

Operation Frequency

450 to 490MHz (K, M) 470 to 512MHz (K2, M2)

400 to 430MHz (K3)

Measurement Range

Vicinity of 10W

3.

Deviation Meter

Frequency Range

450 to 490MHz (K, M) 470 to 512MHz (K2, M2)

400 to 430MHz (K3)

4.

Digital Volt Meter

Measuring Range

10mV to 10V DC

(DVM)

Input Impedance

High input impedance for minimum circuit loading

5.

Oscilloscope

DC through 30MHz

6.

High Sensitivity

Frequency Range

10Hz to 1000MHz

Frequency Counter

Frequency Stability

0.2ppm or less

7.

Ammeter

5A

8.

AF Volt Meter

Frequency Range

50Hz to 10kHz

(AF VTVM)

Voltage Range

1mV to 10V

9.

Audio Generator (AG)

Frequency Range

50Hz to 5kHz or more

Output

0 to 1V

10.

Distortion Meter

Capability

3% or less at 1kHz

Input Level

50mV to 10Vrms

11.

Spectrum Analyzer

Measuring Range

DC to 1GHz or more

12.

Tracking Generator

Center frequency

50kHz to 600MHz

Output Voltage

100mV or more

13.

8

Ω

Dummy Load

Approx. 8

Ω

, 3W

14.

Regulated Power Supply

5V to 10V, approx. 3A

Useful if ammeter equipped

■

The following parts are required for

adjustment

1. Antenna connector adapter

The antenna connector of this transceiver uses an SMA

terminal.

Use an antenna connector adapter [SMA(f) – BNC(f) or

SMA(f) – N(f)] for adjustment. (The adapter is not provided as

an option, so buy a commercially-available one.)

2. Repair Jig (Chassis)

Use jig (part No.: A10-4086-03) for repairing the transceiver.

Place the TX-RX unit on the jig and fit it with screws.

The jig facilitates the voltage check and protects the final

amplifier FET when the voltage on the flow side of the TX-RX

unit is checked during repairs.

3. Battery Jig (W05-1011-00)

+ Terminal (Red)

– Terminal (Black)

Connect the power cable properly between the battery jig

installed in the transceiver and the power supply, and be sure

output voltage and the power supply polarity prior to switching

the power supply ON, otherwise over voltage and reverse

connection may damage the transceiver, or the power supply

or both.

Note:

When using the battery jig, you must measure the

voltage at the terminals of the battery jig. Otherwise, a slight

voltage drop may occur within the power cable, between the

power supply and the battery jig, especially while the

transceiver transmits.

+ Terminal

(Red)

– Terminal

(Black)

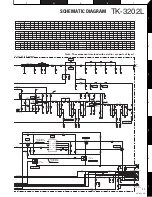

C3

100

µ

/25V

C2

470P/25V

C1

100P/25V

R1

1.8M

–

S

+

Power

supply

Power cable

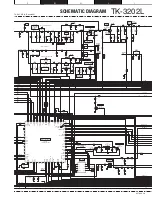

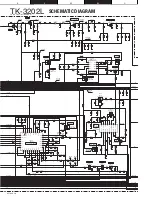

SCHEMATIC DIAGRAM