25

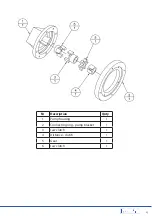

Nr

DESCRIPTION

9

Bushing

12

Nut

17

Support roller

18

Sealing washer TREDO

19

Hydraulic coupling

20

Ramming device - pressure plate

21

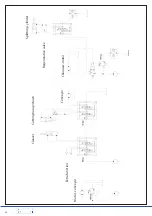

Hydraulic valve - chainsaw

22

Cover plate - Input

23

Hydraulic cylinder

pressure plate

25

Conveyors

26

Adjustable - conveyor belts

27

Cover plate

28

Tank - Chain Oil

29

Cylinder - Input

30

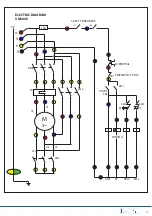

Electric motor

32

Rod with spring

33

Claw coupling

34

Shield over lever valve

35

Valve block

Nr

DESCRIPTION

36

Ventilation plate

37

Input Format

38

Chainswa motor

39

Infeed Roller

40

Lid

48

Bracket for the chain

49

Infeed conveyor belt

65

Nut

66

Washer

67

Bolt

71

Wire reel

72

wire

73

Bolt

77

Chain saw

81

Hydraulic Hose

86

Hydraulic Hose

87

Hydraulic Hose

95

Electric box

96

Hydraulic Hose

97

Hydraulic Hose