KA-175-2T, KA-301-2T

3

EN0B-0320GE51 R0903

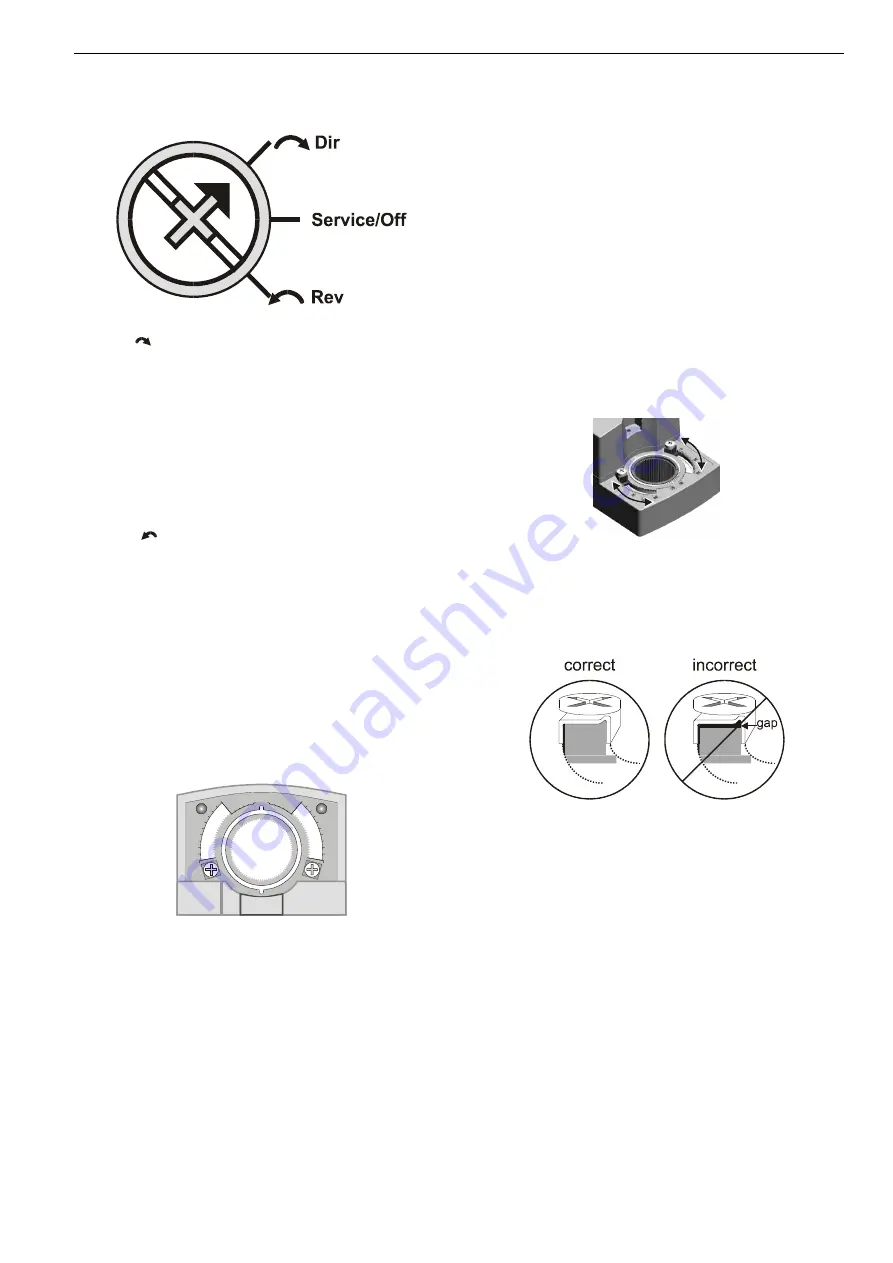

Rotation Direction Switch

Fig. 3. Rotation Direction Switch

•

Dir

("

") is the default shipping position. When the

rotation direction switch is set to this position, the

actuator internally switches the rotation direction control

signals as stated in section "Wiring Diagrams" on pages

Fehler! Textmarke nicht definiert.

•

"

Service/Off

": When the rotation direction switch is set

to this position, all actuator rotary movement is cancelled

and all control signals are ignored, thus enabling the

actuator to be manually operated (see section "Manual

Adjustment"). The user can then perform maintenance /

commissioning without having to remove power from the

actuator. To return to the control mode, simply move the

rotation direction switch to its former setting.

•

Rev

("

"): When the rotation direction switch is set to

this position, the actuator follows signals as stated in

section "Wiring Diagrams" on pages 5 and

Two-Position or Floating Control

The actuator is capable of being operated by either a two-

position (open/close) or a floating (three-wire) controller.

Refer to wiring diagrams for correct connection.

Position Indication

The hub adapter indicates the rotation angle position by

means of the rotational angle scales (0...90° / 90...0°)

provided in the actuator plate (see Fig. 4).

90 90

60

30

60

30

0

0

Fig. 4. Position indication

Manual Adjustment

IMPORTANT

To prevent equipment damage, you must remove

power or set the rotation direction switch to the

"Service/Off" position before manual adjustment.

After removing power or setting the rotation direction switch

to the "Service/Off" position, the gear train can be

disengaged using the declutch button, permitting the actuator

shaft to be manually rotated to any position. The feedback

signal will then follow the new position.

Limitation of Rotation Stroke

Two adjustable mechanical end limits (177 lb-in [20 Nm]

models, only) are provided to limit the angle of rotation as

Fig. 5. Mechanical end limits

The mechanical end limits must be securely fastened in

place as shown in Fig. 6. Specifically, it is important that they

properly mesh with the rotational angle scales when the

screws are tightened.

Fig. 6. Correct / incorrect tightening of end limits