3

1 Transport & handling

1.1

Transport

PSD 5 Industrial belt grinder and others are delivered on a pallet packed in protective

wrapping.

1.2

Handling

The machines can easily be transported on the pallet on which they are delivered. If the

machine is delivered on a pedestal you must insure that the pedestal is secured to the

pallet.

1.3

Placing

Mounting of the machine must take place on a firm level ground. It must be fastened to the

ground by means of the four fittings which are used to fasten the machine to the pallet. It is

provided with no-volt release protection switch and connected for the wanted voltage. The

electrical connection must be performed by an authorized electrician, and it is important to

control that the motor (and the exhaust unit) have the correct direction or rotation (please

see the arrow on the motor).

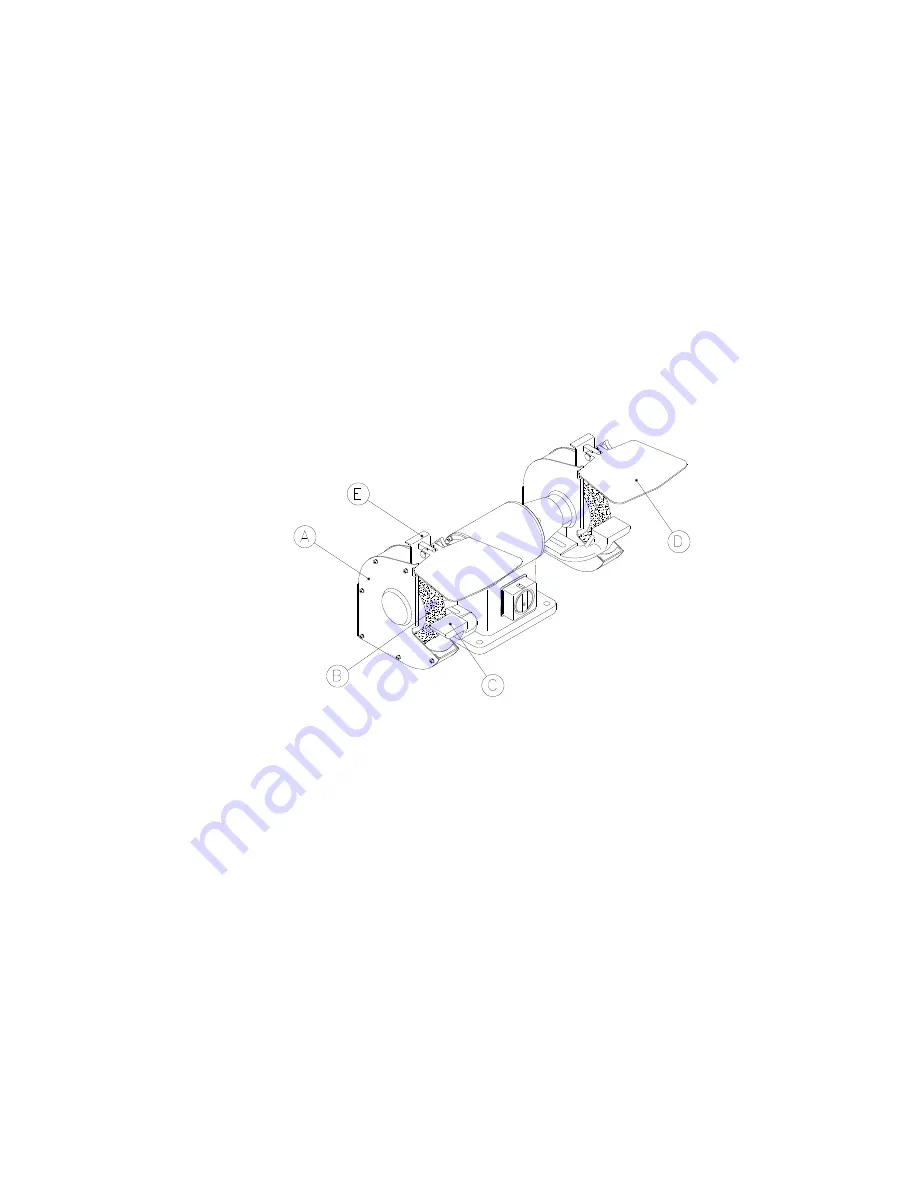

Fig.: 1.1

Before use you must control that the outer cover (A) (se

fig.: 1.1

) is solidly mounted on the

inner cover. The outer cover must stay mounted during use and should only be dismounted

during change of grinding wheel. The grinding wheel (B) must be able to rotate freely

without being loose. The tool rest (C) must be adjusted to a distance of approximately 2 mm

from the grinding wheel.

The eye shield (D) must be clean and adjusted into the right position and the spark arrester

(E) must also be adjusted to a distance of approximately 5 mm from the grinding wheel and

slightly fastened.

The first time you start the belt grinder please let it run at max speed without using it for 5

minutes. Make sure to stay in a safe distance during the machine start-up.