K90-KPCS-IM-2

18/04/22

- 5 -

VENTILATION REQUIREMENTS

INDOOR UNITS:

If the unit is to be located in the machine room,

adequate ventilation air must be provided to avoid an excessive

temperature rise in the machine room. To allow for peak summer

temperatures a maximum rise of 10°F is recommended.

In case of compressors with remote condensers, approx. 10% of

the total heat rejected is given off by compressor and associated

piping. The correct formula for calculating the ventilation require-

ment for indoor parallel compressor unit is:

CFM =

The air intake should be positioned so that air passes over the

units. All State, Local and National codes should be followed.

This ventilation is only for the parallel compressor system. Ad-

ditional ventilation must be taken in to account after considering

other heat loads of the building.

10% of THR (BTU/HR)

10 (°F)

ELECTRICAL INFORMATION

All wiring and connections to the unit must be made in accordance with national as well as local electrical codes and by-laws.

WARNING

Electrical wiring should be sized in accordance with the minimum

circuit ampacity (MCA) shown on the unit nameplate and appli-

cable electrical codes. The unit power connections are approved

for copper wire only.

Connect the field power supply through a properly sized branch

circuit protection disconnect switch. The entering service fuse

must not exceed the maximum overcurrent protection (MOP)

value on the unit data plate.

Field connected control circuit wires are terminated directly at the

control circuit terminal block in accordance with the appropriate

wiring diagram.

Voltage at the unit terminals must not vary more than the allow-

able variation during start-up and while under full load. If the volt-

age is normal at the supply with the compressor not running and

drops considerably when the switch is closed and the motor is

trying to start, there is a high resistance due to undersized wires

or faulty connections. Voltage drop between inoperative and full

load must not exceed 3% of line voltage. In addition, the phase

imbalance at the motor terminals should be within 2% on three

phase units.

Refer to the wiring diagrams shipped with the unit for wiring ar-

rangements.

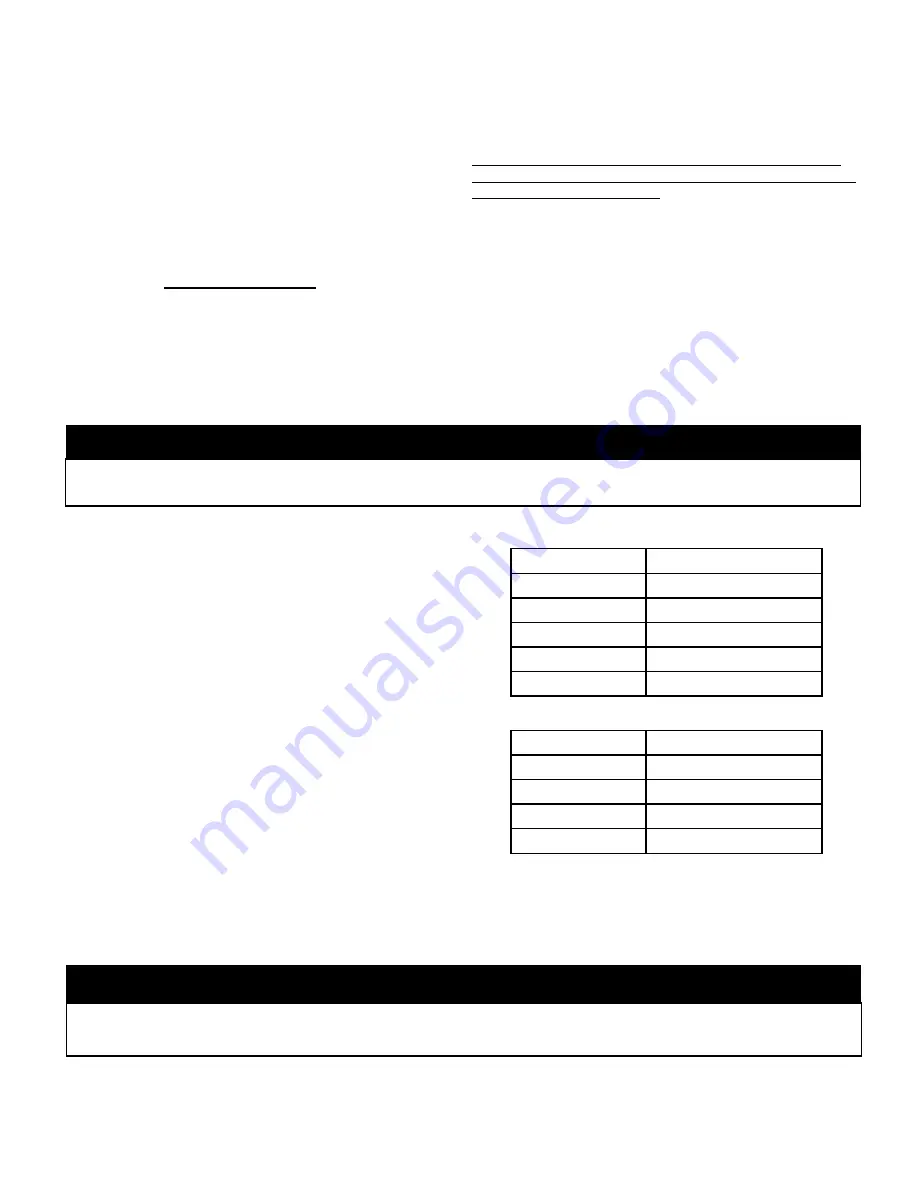

60 Hz Supply

Power

Allowable Variation

115-1-60

103-127 V

208/230-1-60

197-254 V

208/230-3-60

187-254 V

460-3-60

414-506 V

575-3-60

518-632 V

50 Hz Supply

Power

Allowable Variation

100-1-50

90-110 V

200/220-1-50

190-242 V

200/220-3-50

180-242 V

380/400-3-50

342-440 V

Any deviation or change to the electrical components or wiring as supplied on the original equipment, or noncompliance with the volt-

age and phase balance requirements without written authorization will void the warranty.

WARNING