6

EWL 5839

A 8.3 Repairs

Service or repairs of the unit must be carried out only by trained technical personnel.

Modifications by others, and use of unauthorized parts, invalidates the Product Liability.

Use only original spare parts.

A 9 Technical data

Steam Cleaner EWL 5839 1.000.8471 DE (electrical supply line 0.223.4129)

Steam Cleaner EWL 5839 1.000.9671 GB (electrical supply line 0.691.8281)

Steam Cleaner EWL 5839 1.000.9676 US (electrical supply line 0.692.5441)

Steam Cleaner EWL 5839

AU (electrical supply line 0.691.8531)

Voltage:

230 V / 50 Hz

Power:

7.5 Amps

Consumption:

1800 W

Protection class:

IP 43

Method of operation:

Intermittent operation 5 / 5 min.

Working pressure:

Max. 6 bar

Steam temperature:

Max. 164° C at 6 bar indicated

Boiler capacity:

2.2 litres

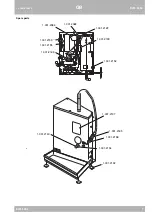

Overall dimensions:

Width 450 mm

Height 570 mm (to top of Housing)

750 mm (incl. Steam-spray hose)

Depth 330 mm

Weight:

31 Kg (plus 2 Kg for footswitch)

Noise emission levels for KaVo Steam Cleaners < 70 dB(A)

Warranty information

Within the scope of the current Delivery and Payment Conditions, KaVo EWL warrants the unit to be free from malfunctions, defects in

both materials and workmanship for a period of 6 months from the date of purchase. At the end of this warranty period, KaVo provides a

further 6-months guarantee for faults arising, which can be traced back to deficiencies in materials or the manufacturing process.

For established complaints, the guarantee covers only the supply or repair of replacements, free of charge. KaVo EWL is not liable for

defects, and their consequences, caused by or which could be caused by normal wear; misuse; improper cleaning or maintenance; failure to

follow the operating, maintenance or electrical regulations; corrosion; air pollution; chemical or electrical influences which are unusual, or

not in accordance with factory regulations.

The guarantee does not apply if defects, or consequential damage, are the result of unauthorized modifications, and alterations to the

product. Entitlement to the guarantee can only be validated if claims are submitted without delay, in writing.

Return of the product must be accompanied by a copy of the invoice or delivery note, on which the serial number is clearly indicated.

Accessories

Mat. No.

Description

1.001.2156

Drawer, complete (Collection tray)

1.001.2158

Lid for drawer

1.001.2159

Footswitch, complete assembled

1.001.2160

Fixings set

1.001.2161

Angled tip for steam-nozzle (not included)

1.001.2162

Wall-mount, complete

1.001.2163

Square socket wrench

1.001.2164

Water drainage hose 1/2“, 1.5 metres long

1.001.2165

Water supply hose, grey, complete – 3/4“ connection, 1.5 metres long

1.001.2166

Hose clips D12x20-9

1.001.2167

Hose connection 3/4“ – 90° elbow for 1/2“ hose