REASSEMBLY

:

Before you begin reassembly of the watermaker, clean all parts using clean, lint-free rags. At this time, all parts

should be carefully inspected for wear or damage. Use a 10x magnifier or loupe to examine the seals, O-rings,

and other small parts. Stubborn rust stains and other deposits on metal parts can be cleaned with a soft-metal

wire brush (e.g., stainless steel or brass). Do

not

use polishes, cleaning compounds containing abrasive materials,

or regular steel wire brushes. During reassembly, refer to

Figures A-3

and

A-4

in the

Appendix

for full-size

drawings and identification of the components included in the Repair Seal Kit.

In the following procedure for reassembling the watermaker, it is assumed that all parts have been cleaned and

that all O-rings, seals, and mating surfaces have been lightly lubricated with non-petroleum silicon grease

(supplied with the Repair Seal Kit). References to the Repair Seal Kit will be abbreviated to “RSK.”

Warning:

Use only non-petroleum silicon grease to lubricate your watermaker. Lubricants with a petroleum

base will damage several watermaker components, including the reverse osmosis membrane. Be especially

cautious of lubricants that “contain”

Teflon, silicon, etc.

—

such products could also contain petroleum-based

components. An ample supply of silicon grease is included with each

RSK

.

1.

Make a note of the correct orientation of the old cup ring and PIP seal and then remove them from the

piston assembly. Since these components are made of rather stiff rubber, it is usually easier to cut them

off. Use a small screwdriver to wedge under the cup seal and pry it up. While holding it up, cut it with a

small pair of scissors. Repeat this process for the PIP ring.

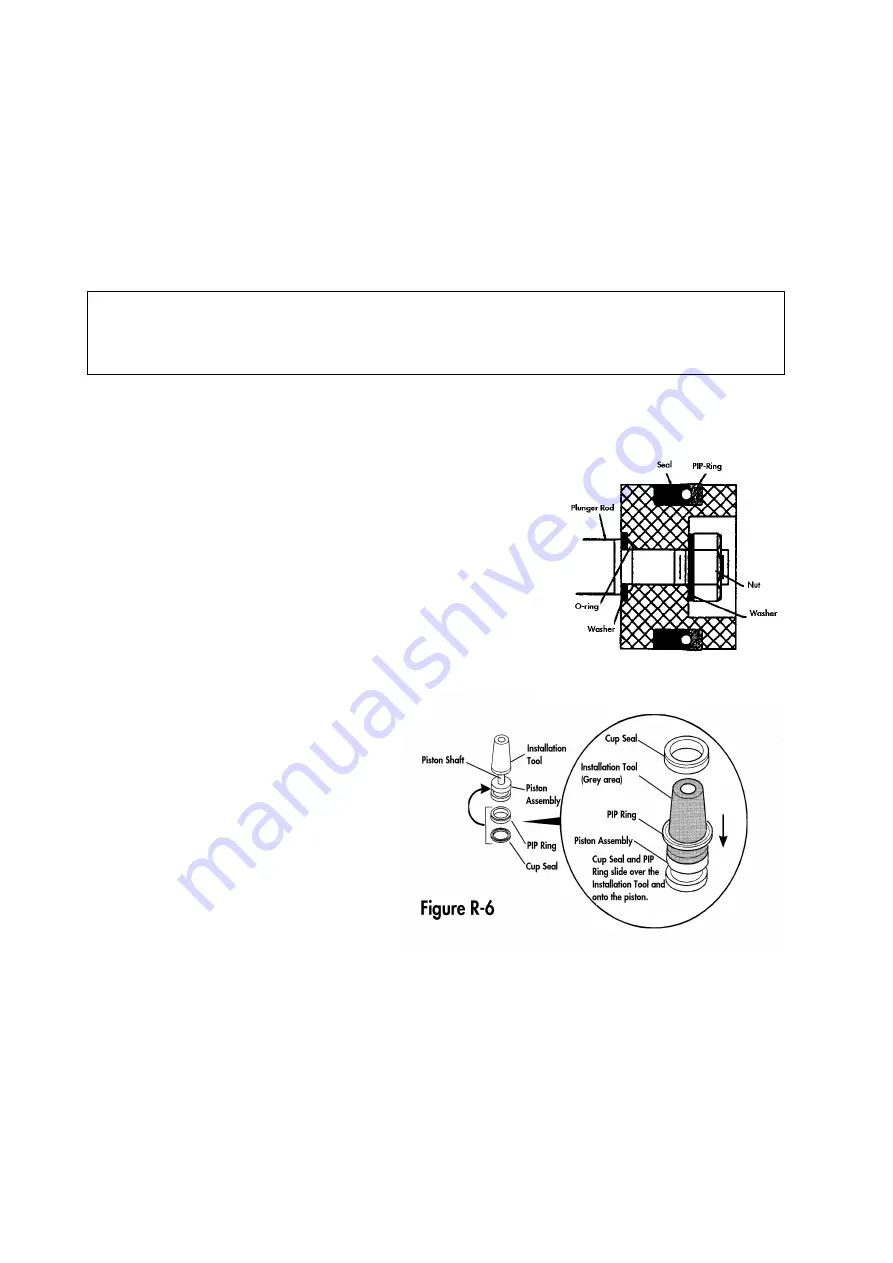

•

Reinstall the piston:

If you want to replace the O-rings on the

piston, refer to the figure below

o

Install washer with chamfer on washer

facing ½” dia

of plunger rod and a new O-ring onto the plunger

rod, if you have an old-style piston, you only have to

install a new O-ring (8013008) into the plunger rod

without a washer.

Slide piston onto the threaded end of the plunger rod, and secure

with the washer and nut as well as one drop of Locktite.

2.

Refer to

Figure R-6

during the following procedure. Place the piston

assembly on a flat, stable surface with the shaft pointing up. Slide

the installation tool (provided in the

RSK

)

over the piston shaft with the wide end

down. Lubricate the new PIP ring, cup seal

and the installation tool with silicon grease.

With the grooved side facing up, slide the

PIP ring down the installation tool and onto

the piston. Repeat this process for the cup

seal. Note that the grooved side of the cup

seal should be facing down, i.e., the

grooved sides of the PIP ring and the cup

seal should be facing each other. When

finished with the installation, remove the

installation tool from the piston shaft.

Note:

This is a very tight fit by design and

will require a fair amount of force to push the PIP ring down the installation tool. You may use an object to

help push the pip ring evenly down the tool. Please make sure not to damage the PIP ring.