5

MAINTENANCE

• If the tool is used every day, disassemble and inspection is recommended

every 6 months.

• Dry the filter and the air inlet of the tool.

• Lubricate the quick connect coupling to prevent blocking.

• Air tools require lubrication throughout the life of the tool. Since the com-

pressed air driving the motor contains water, we recommend water separator

in the air supplying system. The tool must be lubricated daily.

• The supplied compressed air must be clean and dry, with the appropriate oil

mist. Use an air treatment unit; filter, regulator and lubricator.

• Use SAE 10-20 to lubricate the tool, just ad 4-5 drops . In the air inlet before

connected.

• Avoid storing the tool in a location subject to high humidity. If the tool is left as

it is used, the residual moisture inside the tool can cause rust. Before storage,

lubricate tool and run it for a few seconds.

• If the tool is too seriously damaged to be used anymore, recycle raw material

instead of disposing as waste. The machine, accessories and packaging should

be sorted for environmental-friendly recycling. Check with your local authority

or retailer for recycling advice.

• Tools repair and maintenance should be carried out by an authorized service

center.

• To ensure a good performance. The operation pressure at the compressed air

inlet should not exceed 6.3 bar (90psi) (unless indicated otherwise). Higher op-

erating pressures may cause damaged or excessive wear. Operating pressures

below 5.3 bar may cause pressure or power loss.

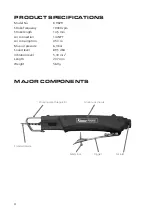

Summary of Contents for K 9829

Page 1: ...K 9829 Air body saw...

Page 8: ...www kamasatools com K 9829...