DMX control mode

DMX channel DMX value Function

Channel 1

000 - 005

0% output

006 - 255

5% - 100% output

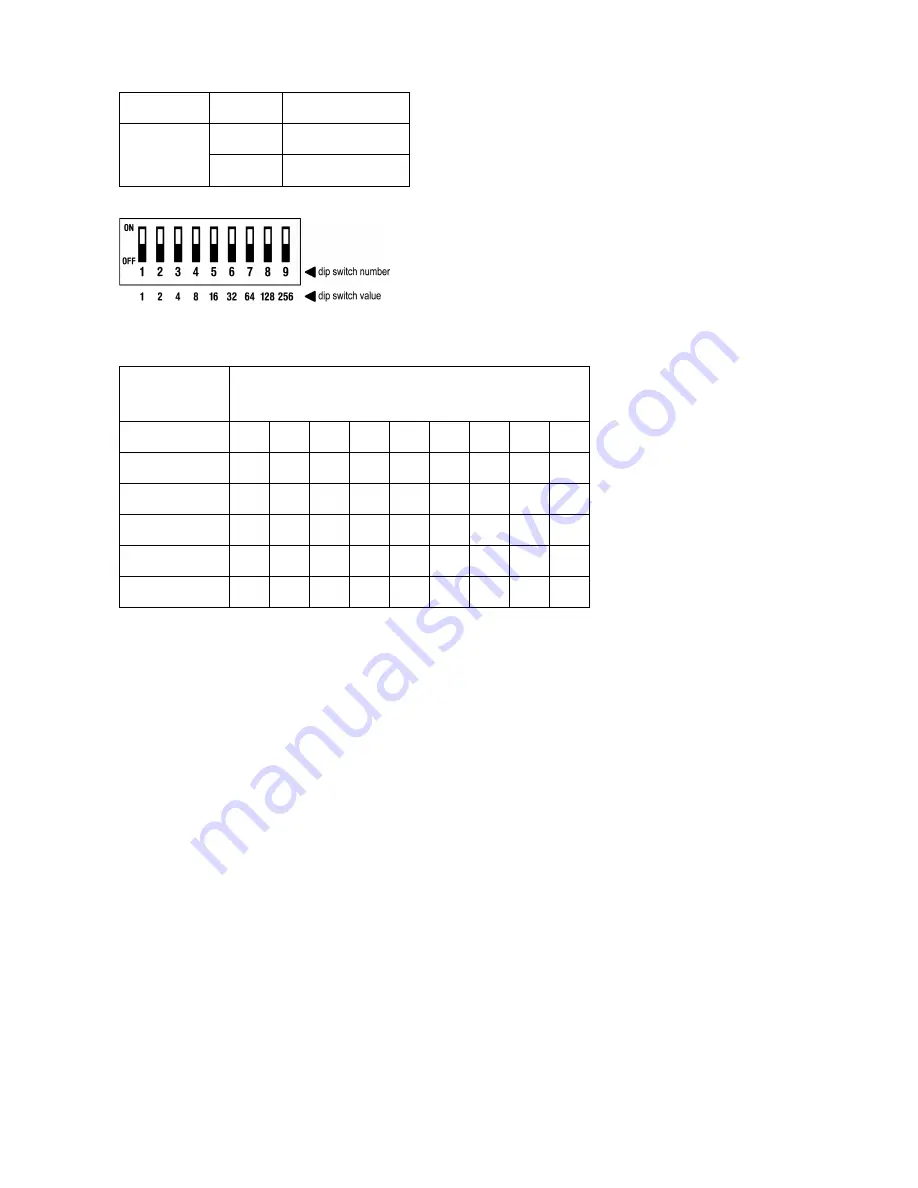

To set the DMX address please see the table below and set using the dip switches on the rear of the unit

(see diagram).

Note: 1 = On, 0 = Off

DMX address

DIP Switches

1

2

4

8

16

32

64

128

256

1

1

0

0

0

0

0

0

0

0

2

0

1

0

0

0

0

0

0

0

3

1

1

0

0

0

0

0

0

0

...

...

...

...

...

...

...

...

...

...

410

0

1

0

1

1

0

0

1

1

Fuse Replacement:

Unplug the IEC power cable before replacing the fuse! Always replace with same type of fuse.

1. Using a flat head screwdriver, remove the fuse holder from the IEC housing.

2. Remove the bad fuse from the fuse holder.

3. Insert the new fuse into the fuse holder.

4. Install the fuse holder in the IEC housing.

Mounting :

Orientation:

This fixture should only be mounted/used on a flat surface. This fixture should not be tilted.

Rigging:

It is important never to obstruct the vents’ pathways. Mount the fixture using, a suitable “C” or “O” type clamp.

When selecting installation location, take into consideration the fluid reservoir access and routine maintenance.

Safety cables must always be used, utilising the provided safety eye bolt.

Never mount in places where the fixture will be exposed to rain, high humidity, extreme temperature changes or restricted ventilation.

General maintenance

To maintain optimum performance and minimise wear, the item should be cleaned frequently. Usage and environment are

contributing factors in determining the cleaning frequency. As a general rule, fixtures should be cleaned after use to avoid dust build-

up and blockages, which can result in poor performance, overheating and breakages. Be sure to uplug the unit from the mains

before

conducting any maintenance. Use a vacuum and a soft brush to remove dust collected on external vents and internal

components. Clean the external case when the unit has

completely

cooled down with a dry cloth or tissue.

Regular maintenance

Be sure to power off fixture

before

conducting any maintenance. Every 40 hours of continuous operation, it is recommended to run a

cleaning solution

composed of 80%

distilled

water and 20% distilled

white vinegar

through the system to prevent the

accumulation of particulate matter in the heating element.

The recommended cleaning regime is as follows:

1. Empty all haze/smoke fluid from the machine.

2. Add the above

cleaning solution

to the tank (80%

distilled

water and 20% distilled

white vinegar

).

3. Plug the unit in to the mains and allow it to warm up.

4. Run the unit in a well-ventilated area until the tank is almost empty.

Do not allow the pump to run dry.

Cleaning is now complete. Refill with haze/smoke fluid. Run the unit briefly to clear any cleaning solution from the system.