Operation Manual

W-2416Z

KAKA Industrial

®

- 7 -

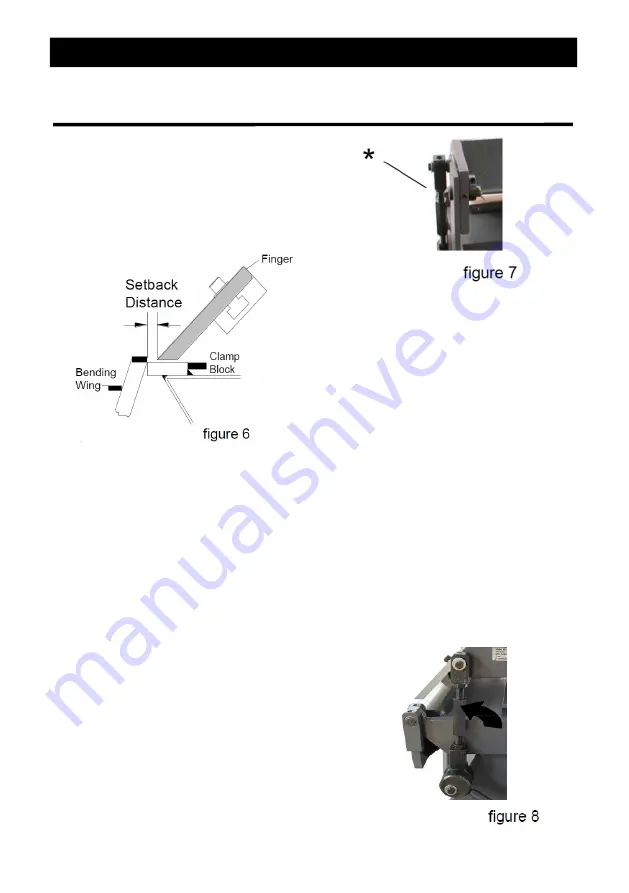

distance is determined by the gauge

(thickness) of the piece part and inside

radius of the bend. The setback is

typically 1-1/2 - 2 times the material

thickness.

1.To adjust, make sure all the fingers are

properly aligned to each other and the

hold down assembly is not locked in the

down position.

2.Loosen the setscrews at the back of the

hold down assembly as indicated by the

“

*

”

in (fig. 7). Insert a tool, such as an

allen wrench, into one of the spooked

holes of the eccentric hub and rotate it,

which moves the hold down assembly

either forward or back. When the fingers

are at the correct setback distance and

parallel to the clamp block edge, tighten

the setscrews

“

*

”

.

Adjusting the Clamping Pressure

The clamping pressure may have to be

adjusted as the thickness of the piece

part changes. A suitable pressure should

have a medium resistance when pulling

back on the hold down handle. At the end

of the stroke there should be a definite

locking of the piece part under the hold

down assembly.

1. Loosen the turnbuckle jam nuts on

both sides of the hold down assembly.

Rotate the two turnbuckles until the

desired tension is reached.

2. Retighten all four jam nuts.