9 Fault Recognition and Rectification

9.1 Basic instructions

1. Do not attempt fault rectification measures other than those given in this manual.

2. Inform KAESER Service if the fault cannot be removed by the action suggested.

Further information Observe the instructions in chapter "Safety" and prevailing local safety regulations when rectifying

faults and malfunctions.

9.2 SIGMA CONTROL MOBIL messages

There are three types of message:

■ Alarm messages, see chapter 9.2.1

■ Warning messages, see chapter 9.2.2

■ Maintenance messages, see chapter 10.2

The messages valid for your machine are dependent on the controller factory settings and individual

equipment with which the machine is provided.

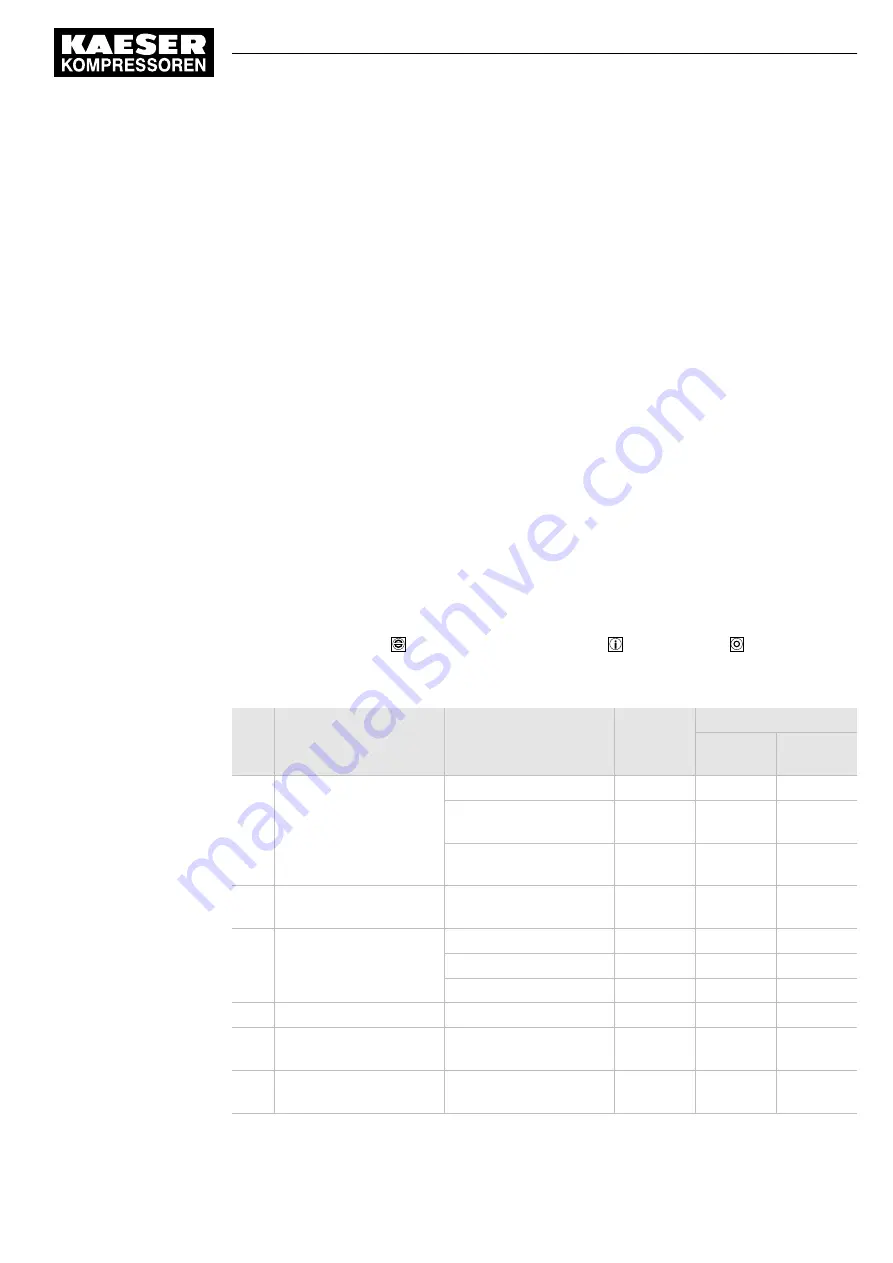

9.2.1 Alarm messages on the controller (machine off)

Alarm with automatic machine shut-down function.

The «Acknowledge» key flashes. The «Information» key and «Stop» key are illuminated.

Message code range 1100 – 1199 “engine faults”

Code Meaning

Remedy

See

chapter

Where can I get help?

Specialised

workshop

KAESER

Service

1100 Oil pressure fault.

Check the engine oil level.

–

–

Have the engine oil pres‐

sure checked.

–

X

–

Have the oil pressure

switch checked.

–

X

X

1101 Oil pressure sensor defec‐

tive.

Have the sensor changed.

–

X

X

1110 Coolant temperature high. Check the coolant level.

–

–

Clean the radiator.

–

–

Check the cooling system.

–

X

X

1111 Coolant level too low.

Check the coolant level.

–

–

1112 Coolant temperature sen‐

sor defective.

Have the sensor changed.

–

X

X

1120 Turbo air pressure too

high/low.

Have the turbo air pres‐

sure sensor checked.

–

X

X

9

Fault Recognition and Rectification

9.1

Basic instructions

No.: 9_6975 00 E

Service Manual Screw Compressor

M135 SIGMA CONTROL MOBIL

85