Mounting

While holding the coupler in place measure back from the assembled couplers

pulling face 15/16” and mark the location. Make sure the trucks will clear the

back of gear box on your tightest radius curve. You may need to trim the trucks,

coupler gear box or move the mounting hole closer to the end of the car for truck

clearance. Now using the Kadee

®

#246 Tap & Drill set, drill a tap hole for a 2-56

screw with a #50 drill, and then tap the mounting hole on the scribed centerline.

Burnish the mounting surface & bottom of the gearbox with #231 Greas-em. Now

mount the assembled coupler on the centerline of car with the 2-56 x 3/8” screw

provided (if screw is to long use appropriate length flat machine screw) through

the Centering Bushing. (Note: the Bushing spring may dislodge easily until the

2-56 screw is secured.) Make sure the gearbox is in line with the centerline of

the car before snugging down the screw. The gearbox should move freely and

snap back to the centerline.

FINAL CHECKS

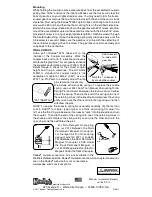

Add a puff of Kadee

®

#231 Greas-em on the

insides of the Coupler Assembly. Work the

coupler back and forth to lubricate and evenly

distribute the graphite. This will greatly enhance

the coupler’s performance. Use our #205 or #206

Height Gauge to check for the correct coupler

height and trip pin clearance. The HO-Scale

N.M.R.A. standard for coupler height is the

centerline of coupler at 25/64” (.390”). Use our

#237 Trip Pin Pliers to carefully adjust the trip

pin clearance if necessary.

We include extra knuckle springs. To replace the knuckle

spring, use our #241 Dual Tool (Manual Uncoupling Tool &

Spring Pic) and insert it between the last two coils on either

end of the spring. Then slip the end of the spring onto one of

the retaining cones in the knuckle and compress the spring

until you can slip the other end onto the opposing cone then

withdraw the pick.

NOTE: To secure the knuckle spring more durably carefully dip the last two

coils in DUCO

®

(or similar type of glue) or a thick slow drying CA glue (“do

not” use the thin CA glue because it can easily “wick” into the knuckle and ruin

the coupler). Then slip the end of the spring onto one of the retaining cones in

the knuckle and compress the spring until you can slip the other end onto the

opposing cone then withdraw the pick.

For Non-Delayed Uncoupling

use our #312 Between the Rails

Permanent Magnet Uncoupler.

For Delayed Action Uncoupling

use our code 100 #321 or code 83

#322 Between the Rails Permanent

Magnet Uncoupler, #308 Under

the Track Permanent Magnet, or

our #309 Magne-Electric (Electro-

Magnet) Under the Track Uncoupler.

Kadee

®

coupler conversion lists are available in the

Walthers Reference Book. Kadee

®

coupler conversion list & coupler conversions

are on the Kadee

®

web site for your convenience.

www.kadee.com/conv/convpl.htm

Add Greas-em

to inside draft

gear box

Work the Greas-em in

by moving the coupler

#

241 “Dual Tool”

Made & Assembled Entirely

in the U.S.A.

673 Avenue C • White City, Oregon • 97503 -1078 U.S.A.

© 2011 Kadee

®

Quality Products Co.

010611

Quality Products Co.

WARNING:

CHOKING HAZARD - Small Parts

Not for children under 14 years.