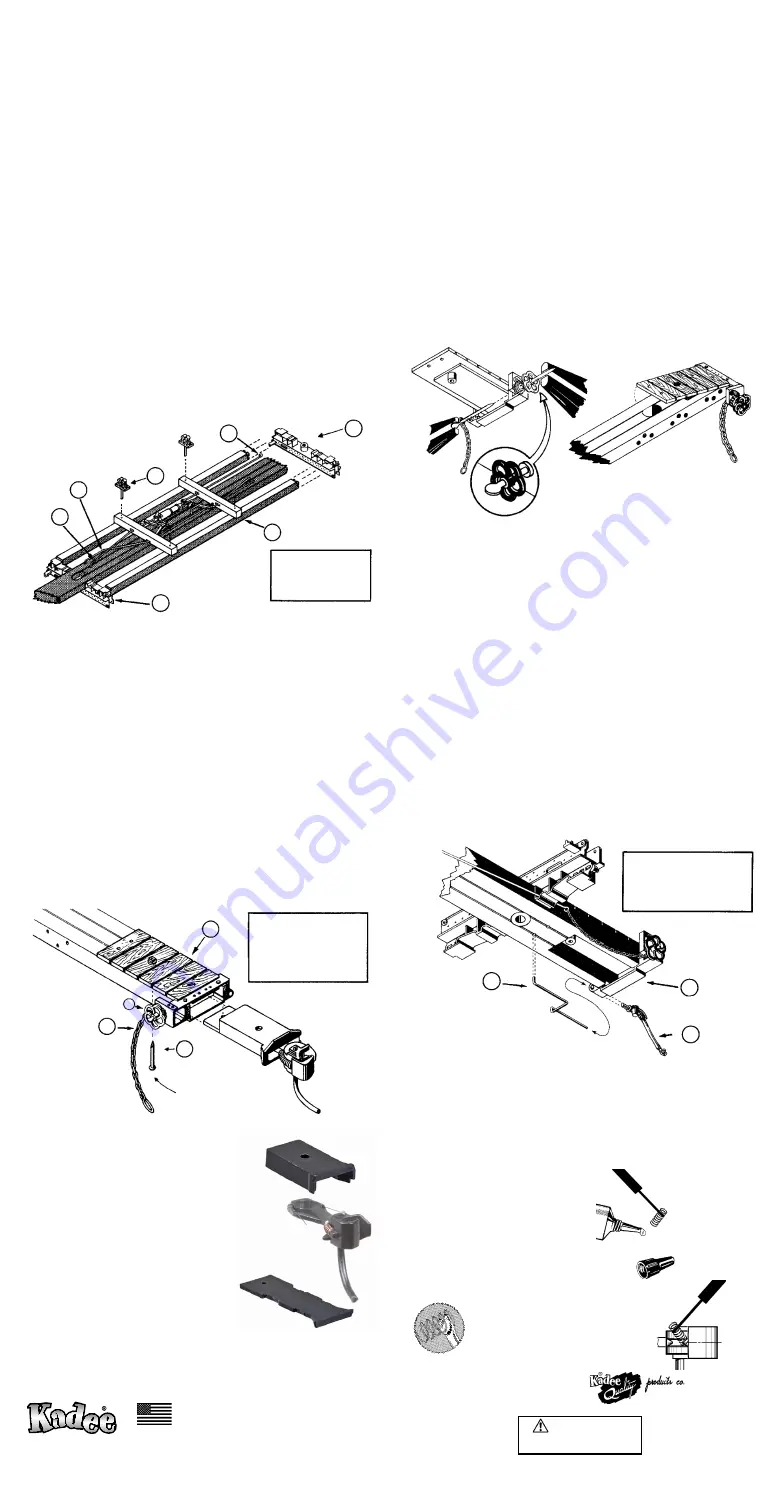

K-2 BRAKE SYSTEM: Be certain end of center sill (15) to bear brake wheel

has been identified. Begin by placing air tank (1) with tapered end toward

brake wheel end of car as seen in Fig. C, exploded view. Note that lever (2)

has a clevis projection to enter into end of air tank (see Fig. D). Fit these

together, then enter mounting studs of these parts into proper holes In center

sill (15). Do this once on a trial basis without cement to gain a better idea of

the procedure. Next, mounting studs of lever (3) are entered into holes In

car body and at the same time, Insert rod (5) into clevis openings of levers

(2) and (3) as seen In Figs. C and D. Use cement on the joined parts.

Dirt trap (4), briefly mentioned earlier, is to be detached from Its original

position as It comes joined to the triple valve on end of air tank (1). It Is to

be swung around to form a right angle with the air tank (Fig. D). Note also,

air line pipe (8) must pass through opening of tee on end of dirt trap piping

(4). One end angle of pre-bent pipe (8) can be reduced, using pliers, to allow

It to pass through dirt trap tee. When this has been done restore bend In

pipe to former angle. Slide dirt trap assembly along pipe (8) until correctly

positioned to cement free end of piping Into elbow on triple valve at end of

air tank (see Figs. C and D). Cement ends of (8) Into center sill.

A halt must be called In brake system assembly at this point. This Is because

two rods (7) and another rod (6) must pass through slots In cross bearers

(20A and 20B) of the truss system. This can be seen In Fig. L. Rod (6) must

also pass through an opening In the end bunk closest to the brake wheel

(Fig a.). These rods are to be added later.

Three staples (10) are supplied as supports, one for lever (3) and two for

lever (2), as seen In Fig. C. These can be Installed and cemented now.

ASSEMBLING TRUSS SYSTEM TO MODEL:

Center stud projections of

end bunk assemblies (23) are entered into extreme outer ends of elongated

holes In center sill (15) so bunks are spread as far apart as possible. Flashing

may be found on sides of center stud, make sure these areas are clean

for a proper fit. Enter ends of truss rods (21) through holes in queen posts

(22), (Sea supplement Instruction sheet for further clarification’ feeding one

queen post onto each end of each pair of rods. Handle these rods carefully

since they will bend under pressure. Next, enter queen post shank pins into

holes In cross bearers (20A and 20B). Truss rods can be kept in alignment

much better If the piece of paper (supplied) Is entered through the open

turnbuckles across the complete set of rods. This prevents them from twisting

around temporarily, then the paper can be removed once rods are secured

Into end bunks. Now secure the rod ends Into the end slot of sill. (Refer to

supplementary Instruction data Fig. U-1). Place this whole truss assembly

on underside of center sill, being sure notches in the bearers fit properly

over pipe “8” and align the holes on truss system with the posts on center

sill (15). Once the truss system Is located on center sill, slide end bunks

(23) toward extreme Inner ends of elongated holes In center sill, capturing

the truss system between the two end bunks.

COUPLER AND DRAFT GEAR:

Be sure

end castings (16 and 17) are clear of

flashing in all openings, especially where

the thin ends of the center sill enter these

castings. Note: End casting (16) bears a

ratchet assembly to carry the brake wheel,

this fits at car end earlier marked with a

letter “B”. Thus It Is properly placed to

accept the rod from the brake system. End

casting (17) without brake ratchet, naturally

fits the opposite end.

Now before proceeding further, flatten the

head of the short 1/2” common pin with a

pair of pliers. Thread It through the end link

of the 5/8” piece of chain as shown In Fig.

O. Next push pin all the way Into the hole on the Inside of end casting (16)

and out through the brake ratchet. Put brake wheel on exposed pin end and

cut off pin leaving about 1/16” protruding beyond brake wheel. With pliers,

pinch pin as close to brake wheel as possible to flare It, cut off just enough

of the flat so the wheel will not come off. (See Fig. O and Fig. P). Slide end

castings onto ends of center sill (see Fig. N). Once the couplers have been

fitted to the draft gear, enter these assemblies into end castings. Apply a

little Kadee

®

#231 “Greas-em”, burnishing and polishing will greatly reduce

friction of working parts and improve coupler performance. Assemble the

coupler as shown in Fig. R. Add #231 “Greas-em” to Inside of coupler unit

and work coupler back and forth. Be sure coupler consistently snaps back

to center position before continuing further. Slide assembled draft gear unit

into the end casting as shown in Fig. M and secure draft gear boxes to end

sills by Inserting pins (18) In mounting holes (see Fig. M and C). Position

rod (6) in holes In cross bearer (20B) and log bunk (23) but do not secure to

lever (2) yet. Now capture the end link of the 5/8” chain, from brake wheel,

with the looped end of brake rod (6). Close the loop with pliers to secure the

chain. Cement straight end of rod (6) Into clevis on lever 2 (see Fig. a and

Fig. C). Use our #205 or #206 coupler height gauge to check for the correct

height and trip pin clearance. The HO-Scale N.M.R.A. standard for coupler

height is the centerline of coupler at 25/64” (.390”). Use our #237 Trip Pin

Pliers to carefully adjust the trip pin clearance if necessary.

FINAL ASSEMBLY: The two brake rods (7) can now be entered through

slots In cross bearers so their straight ends cement Into clevis openings of

levers (2 and 3). The bent ends of rod cement into holes In center sill (see

Fig. L). Install two air pipes (9), one at each end of car, by entering straight

end of the rods into openings In end casting at rear of where air hoses (14)

are located, then enter bent end Into hole In center sill. All this can be seen

In Fig. a. To prevent wheels from hitting center sill (15) on extremely tight

radius curves, carefully scoop out wheel wells with a Sharp blade at the points

where wheels touch sill. Likewise, on extremely tight curves, the bearing

pad of truck frame could pass beyond corresponding pad on underside

ends of end bunks, thus they might stub and catch when returning from

the curve. To remedy this, file the top of truck bearing pad slightly round as

seen In Fig. C (Inset).

Now the two center bunks (24) can be installed In the holes on the side sills

(19) and across the center sill (15). These bunks are to be located directly

over the cross bearers (20A and 20B). Insert 2-56 screw (33) through truck

frame (32), then through king pin bearing plate (31) (with sprue removed)

and thread Into center stud of end bunks located In center sill (see Fig. C).

Finally, cement air hoses (14) Into openings at side of end castings (Fig. a).

Like this model !!! Then try our other super fine “Masters Builders” kits.

#102 Skeleton Log Flat Is the same as the #103 except It has no truss

system, and only two bunks. The #101 Disconnected Log Car Is a unique log

hauling arrangement. The #104 Industrial Caboose Is designed after logging

prototypes. All cars are equipped with Kadee

®

Magne-Matic

®

couplers.

3. Place glued end

over the knuckle

retaining post and

t h e n c o m p r e s s

spring so that it

may slip over the

opposing shank

retaining post. See

Fig. 3.

4 . C a r e f u l l y

remove pic from

spring.

Fig. 2.

673 Avenue C

White City, Oregon 97503- 1078 U.S.A.

© 2008 Kadee

®

Quality Products Co. 62008

Fig. 3.

GLUING INSERT

To prevent losing knuckle springs by being

dislodged use the following steps and supplies.

Kadee

®

#

241 Dual Tool (Manual Uncoupling Tool

& Spring Pic), small piece of blue denim cloth,

DUCO

®

CEMENT or WALTHERS

®

GOO

®

,

or

similar type cement.

CAUTION:

Always follow

safety instructions for the cement that you may

be using.

1. To pick up spring place it on the cloth (this

allows the small springs to be seen and picked

up easier) and insert

#

241 Dual Tool (Manual

Uncoupling Tool & Spring

Pic) into spring between

coils near one end. See

Fig. 1.

2. Touch one end of the spring into the cement

so that no more than one or two coils are

coated (too much cement will hamper coupler

performance). See Fig. 2.

Fig. 1.

WARNING:

CHOKING HAZARD - Small Parts

Not for children under 14 years.

Made Entirely

in the U.S.A.

071310

673 Avenue C,

white City, OR 97503-1078

© 2010, Kadee

®

Quality Products Co.

Quality Products Co.

7

8

22

6

23

19

23

Fig. L

details such as

stakes and chains

have been omitted

Fig. O

Fig. P

Fig. N

details such as stakes

and chain, truss system,

couplers and draft gear are

left out here for clarity.

9

16

14

Fig. Q

brake

rod (6)

passes

through

opening

in bunk

clean flashing from inside

of all openings so ends of

center sill and draft gear

may fit into end castings

with ease!

16

11

18

12

Fig. M

Fig. R