3-4

NOTE:

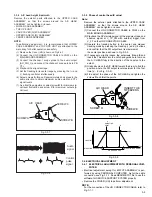

To prevent the tape from damage, turn the guide rollers

slowly.

(7) By operating the tracking button (both in + and - directions)

in the manual tracking mode, vary the output level of the

FM waveform from maximum to minimum and vice versa to

confirm that the waveform varies nearly in a flat shape.

(8) When the FM waveform breaks in the level varying process,

subtly adjust the height of guide rollers at every breaking

point so that the waveform varies as flat as possible.

Repeat the above steps 6. and 7. several times to confirm

that the waveform is flat as a whole.

(9) Playback the SP stairstep signal of alighment tape and ad-

just the tracking control to maximize the FM waveform,

confirm that FM waveform variation is always flat.

(10) Record the signal and play it back in both of the SP and EP

modes, and confirm that the FM waveform is flat in both

modes.

NOTE:

Among the above-mentioned adjustment steps, the

items of No.9 and No.10 are needed for the EP model

only.

Fig.3-3-5

Fig.3-3-6

(11) Through the above steps, confirm that there occur no wrin-

kling and damage in the tape around the PINCH ROLLER

and TU GUIDE POLE whenever the deck is in operation of

Loading/Unloading, Search Rewind and at mode change

from Search Rewind to play mode. If wrinkling or damage

in the tape occurs around the TU GUIDE POLE, adjust the

angle (slant) of the A/C HEAD to the tape. So that the tape

normally runs along the lower flange of the GUIDE POLE.

CH-2

CAUSER BY WRONG HEIGHT

OF SUPPLY GUIDE ROLLER

CAUSED BY WRONG HEIGHT

OF TAKE-UP GUIDE ROLLER

FLATTEN WAVEFORM.

1 field

CORRECT VARIATION OF WAVEFORM

BAD VARIATION OF WAVEFORM

Fig.3-3-3

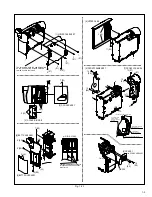

3.3.3 Tape pattern

Remove the exterior parts attached to the UPPER CASE

ASSEMBLY so that the guide roller beside the DRUM ASSEMBLY

can be rotated.

• LOWER CASE ASSEMBLY

• TOP OPE UNIT

• CASE COVER(S),(M) ASSEMBLY

• UPPER CASE (S),(M) ASSEMBLY

NOTE:

In performing adjustment, it is recommended that LOWER

CASE ASSEMBLY and TOP OPE UNIT are attached to the

main body for better operation and safety.

Fig.3-3-4

(1) Remove the Cover (JIG) shown on Fig.3-4-1.

(2) Connect the JIG CONNECTOR CABLE to CN25 on the

MAIN BOARD ASSEMBLY as shown on Fig. 3-2-2.

(3) Observe signal at V_TP_FM with external trigger from

V_FF on the JIG CONNECTOR CABLE.

(4) Playback the SP stairstep signal of the alignment tape and

maximize the FM waveform by the tracking button.

(5) Set the tracking control to the center position by simulta-

neously pressing the tracking (-) and (+) buttons and max-

imize the FM waveform by the tracking button.

(6) If the observed FM waveform is not flat, adjust the height of

the SUPPLY of TAKE-UP GUIDE ROLLER with the roller

driver.

BACK TENSION

0.97x10

-3

- 1.71x10

-3

N

•

m

(10-17gf·cm)

PLAY TORQUE

1.47x10

-3

- 2.45x10

-3

N·m

(15-25gf·cm)

POLE BASE (TU)

(GUIDE ROLLER)

POLE BASE (SUP)

(GUIDE ROLLER)

JIG CONNECTOR CABLE

MAIN CN25 - JIG BOARD

12PIN(V_TP_FM)

13PIN(V_FF)

ALIGNMENT TAPE