3-3

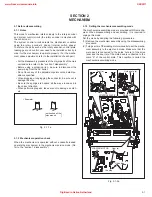

3.2.3 Height and tilt of the A/C head

Note:

• Set a temporary level of the height of the A/C head in

advance to make the adjustment easier after the A/C

head has been replaced. (See “section 2 mechanism”.)

(1) Play back the alignment tape (A).

(2) Apply the external trigger signal to D.FF (E), to observe

the AUDIO OUT waveform and Control pulse waveform

at the measuring points (D1) and (D2) in the ALT mode.

(3) Set the VCR to the manual tracking mode.

(4) Adjust the AUDIO OUT waveform and Control pulse

waveform by turning the screws (1), (2) and (3) little by

little until both waveforms reach maximum. The screw (1)

and (3) are for adjustment of tilt and the screw (2) for azi-

muth.

Signal

(A)

•

Alignment tape(SP, stairstep, PAL) [MHPE]

Mode

(B)

•

PB

Equipment

(C)

•

Oscilloscope

Measuring point

(D1)

•

AUDIO OUT terminal

(D2)

•

TP4001 (CTL. P)

External trigger

(E)

•

TP111 (D.FF)

Adjustment part

(F)

•

A/C head [Mechanism assembly]

Specified value

(G)

•

Maximum waveform

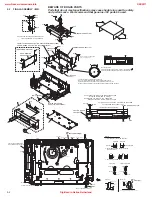

Head base

A/C head

AUDIO OUT

CTL. P

(1)

(2)

(3)

Fig. 3-2-3a

• Proper waveform variation

• Improper waveform variation

A

B

C

D

Up

Down

Guide roller

(supply side)

Roller driver

Fig. 3-2-2b

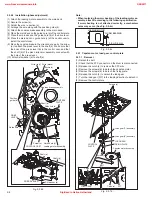

3.2.2 FM waveform linearity

Signal

(A1)

•

Alignment tape(SP, stairstep, PAL) [MHPE]

(A2)

•

Alignment tape(LP, stairstep, PAL) [MHPE-L]

Mode

(B)

•

PB

Equipment

(C)

•

Oscilloscope

Measuring point

(D)

•

TP106 (PB. FM)

External trigger

(E)

•

TP111 (D.FF)

Adjustment part

(F)

•

Guide roller [Mechanism assembly]

Specified value

(G)

•

Flat V.PB FM waveform

Adjustment tool

(H)

•

Roller driver [PTU94002]

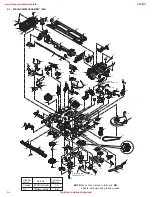

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe

the V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

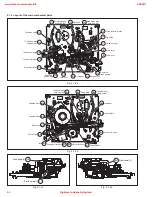

(4) Make sure that there is no significant level drop of the V.PB

FM waveform caused by the tracking operation, with its

generally parallel and linear variation ensured. Perform the

following adjustments when required. (See Fig. 3-2-2b.)

(5) Reduce the V.PB FM waveform by the tracking opera-

tion. If a drop in level is found on the left side, turn the

guide roller of the pole base assembly (supply side) with

the roller driver to make the V.PB FM waveform linear.

If a drop in level is on the right side, likewise turn the guide

roller of the pole base assembly (take-up side) with the

roller driver to make it linear. (See Fig. 3-2-2b.)

(6) Make sure that the V.PB FM waveform varies in parallel

and linearly with the tracking operation again. When re-

quired, perform fine-adjustment of the guide roller of the

pole base assembly (supply or take-up side).

(7) Unload the cassette tape once, play back the alignment

tape (A1) again and confirm the V.PB FM waveform.

(8) After adjustment, confirm that the tape wrinkling does not

occur at the roller upper or lower limits. (See Fig. 3-2-2a.)

[Perform adjustment step (9) only for the models

equipped with SP mode and EP (or LP) mode.]

(9) Repeat steps (1) to (8) by using the alignment tape (A2).

(a) GUIDE ROLLER

(b) GUIDE POLE

Improper

Proper

Fig. 3-2-2a

www.freeservicemanuals.info

3/28/2017

Digitized in Heiloo Netherland