(No.YF042)1-7

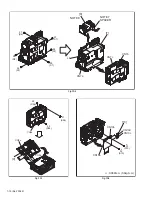

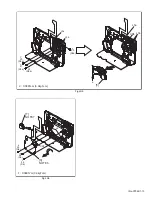

3.2.2 ASSEMBLY/DISASSEMBLY OF CABINET PARTS AND ELECTRICAL PARTS(1)

z

Disassembly procedure

Fig.3-2-1

NOTE2:

For disassembly of the MONITOR ASSEMBLY, see "3.2.6

DISASSEMBLY of [12] MONITOR ASSEMBLY".

NOTE5a:

Another FPC overlaps the FPC of the VF ASSEMBLY. Be-

fore removing the FPC of the VF ASSEMBLY, remove

CN5a.

NOTE5b:

For disassembly of the VF ASSEMBLY, see "3.2.4 DISAS-

SEMBLY of [5] VF ASSEMBLY".

NOTE7:

In removing the LOWER ASSEMBLY, remove the SPAC-

ER, and remove the FPC.

Be careful not to damage the FPC.

NOTE8:

For disassembly of the OP BLOCK ASSEMBLY, see "3.2.5

DISASSEMBLY of [8] OP BLOCK ASSMBLY/CCD BOARD

ASSEMBLY ".

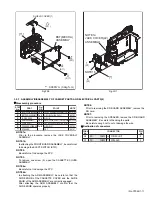

z

Destination of connectors

Fig.3-2-2

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

TOP COVER ASSEMBLY

UPPER CASE ASSEMBLY

(Inc. MONITOR ASSEMBLY)

REAR COVER ASSEMBLY

FRONT COVER ASSEMBLY

(Inc.MIC ASSEMBLY)

VF ASSEMBLY

BASE

LOWER ASSEMBLY

(Inc. FRONT BOARD ASSEMBLY/

SD BOARD ASSEMBLY)

OP BLOCK ASSEMBLY/

CCD BOARD ASSEMBLY

MAIN BOARD ASSEMBLY

MDA BOARD ASSEMBLY

MECHA ASSEMBLY

2(S1a),2(S1b),CN1

(S2a),(S2b),4(S2c),2(L2a),2(L2b)

CN2a,b

CN3,4(S3),4(L3)

(S4a),(S4b),JACK COVER(AV)ASSEMBLY

2(S4c),CN4

CN5a,b,2(S5),L5

2(S6)

CN7a,SPACER,CN7b,c,4

㧔

S7

㧕

2(S8),L8

CN9a,b,(S9a),2(S9b),CN9c

CN10a,b,c,d,2(S10)

(S11),SHIELD COVER(1),3(S11)

BKT(MECHA)ASSEMBLY

Fig.FA1

Fig.FA2

Fig.FA3

Fig.FA4

Fig.FA5

Fig.FA6

Fig.FA7

Fig.FA8

Fig.FA9

-

NOTE2

-

-

NOTE5a,b

-

NOTE7

NOTE8

-

-

-

STEP

No.

PART

NOTE

Fig.

No.

POINT

CONNECTOR

PIN.

No

CONN.

No.

CN1

MAIN

CN109

ZOOM SW(OPE)

-

6

CN2a

MAIN

CN112

MONITOR

CN7601 39/20,

/CN7602 20

CN2b MAIN

CN110

JUNCTION

CN401 10

CN3 MAIN CN104 REAR

CN501 40

CN4 MAIN CN107 MIC

ASSY -

4

CN5a MAIN

CN105

SD

CN901 22

CN5b

MAIN

CN103

VF FPC ASSY

-

22

CN7a FRONT CN701

MAIN

CN108 24

CN7b MAIN

CN102

CCD

CN5201 20

CN7c

MAIN

CN101

OP BLOCK ASSY

-

24

CN9a MAIN

CN106

MDA

CN305 30

CN9b MAIN

CN113

HEAD

-

8

CN9c MAIN

CN114

SENSOR

-

16

CN10a MDA

CN301

CAPSTAN

MOTOR

-

18

CN10b MDA

CN302

DRUM

MOTOR

-

11

CN10c MDA

CN303

ROTARY

ENCODER

SW -

6

CN10d MDA

CN304

LOADING

MOTOR

-

6