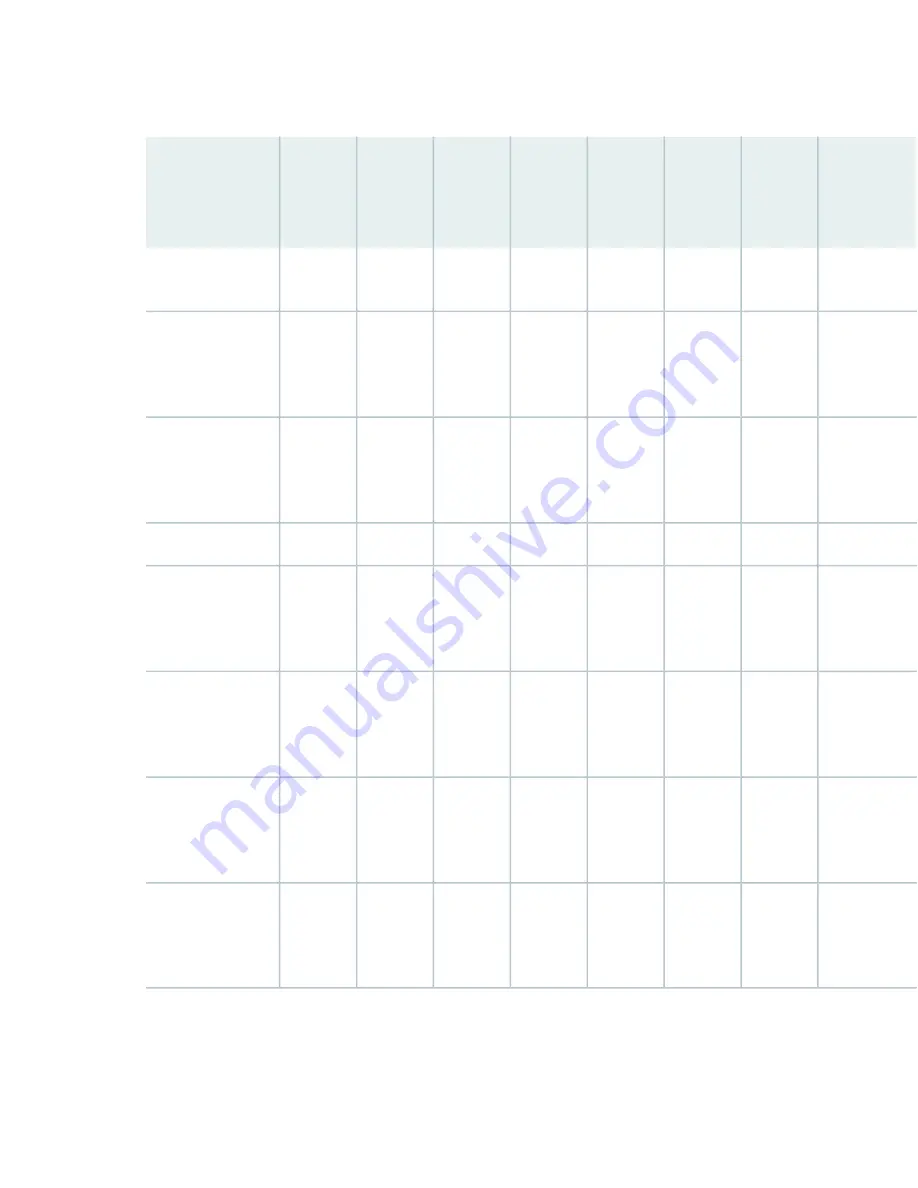

Table 34: Total Power Available

Ten Power

Supplies

(redundancy

only)

With

Nine

Power

Supplies

With

Eight

Power

Supplies

With

Seven

Power

Supplies

With Six

Power

Supplies

With

Five

Power

Supplies

With

Four

Power

Supplies

With

Three

Power

Supplies

Power Supply

Module Models

24,300

W

21,600 W

18,900 W

16,200 W

13,500 W

10,800 W

8100 W

JNP10K-PWR-AC

49,500 W

44,000 W

38,500 W

33,000 W

27,500 W

22,000 W

16,500 W

JNP10K-PWR-AC2

dual feed, high

power (30-A)

setting

45,000 W

40,000 W

35,000 W

30,000 W

25,000 W

20,000 W

15,000 W

JNP10K-PWR-AC2

single feed, high

power (30-A)

setting

22,500 W

20,000 W

17,500 W

15,000 W

12,500 W

JNP10K-PWR-DC

49,500 W

44,000 W

38,500 W

33,000 W

27,500 W

JNP10K-PWR-DC2

dual feed, high

power (80-A)

setting

39,600 W

35,200 W

30,800 W

26,400 W

22,000 W

JNP10K-PWR-DC2

dual feed, low

power (60-A)

setting

24,750 W

22,000 W

19,250 W

16,500 W

13,750 W

JNP10K-PWR-DC2

single feed, high

power (80-A)

setting

19,800 W

17,600 W

15,400 W

13,200 W

11,000 W

JNP10K-PWR-DC2

single feed, low

power (60-A)

setting

101

Summary of Contents for MX10016

Page 1: ...MX10016 Universal Routing Platform Hardware Guide Published 2019 10 15 ...

Page 19: ......

Page 86: ......

Page 123: ......

Page 153: ......

Page 239: ...Figure 118 Moving the MX10016 Using a Mechanical Lift g100421 242 ...

Page 240: ...5 CHAPTER Troubleshooting Hardware Restoring Junos OS 245 Alarm Messages 249 ...

Page 241: ......

Page 249: ......

Page 277: ...Restricted Access Warning 281 ...

Page 292: ...Jewelry Removal Warning 296 ...

Page 295: ...Operating Temperature Warning 299 ...

Page 304: ...DC Power Disconnection Warning 308 ...

Page 308: ...DC Power Wiring Sequence Warning 312 ...

Page 311: ...DC Power Wiring Terminations Warning 315 ...

Page 320: ...Translation The emitted sound pressure is below 92 dB A per GR63 CORE 324 ...