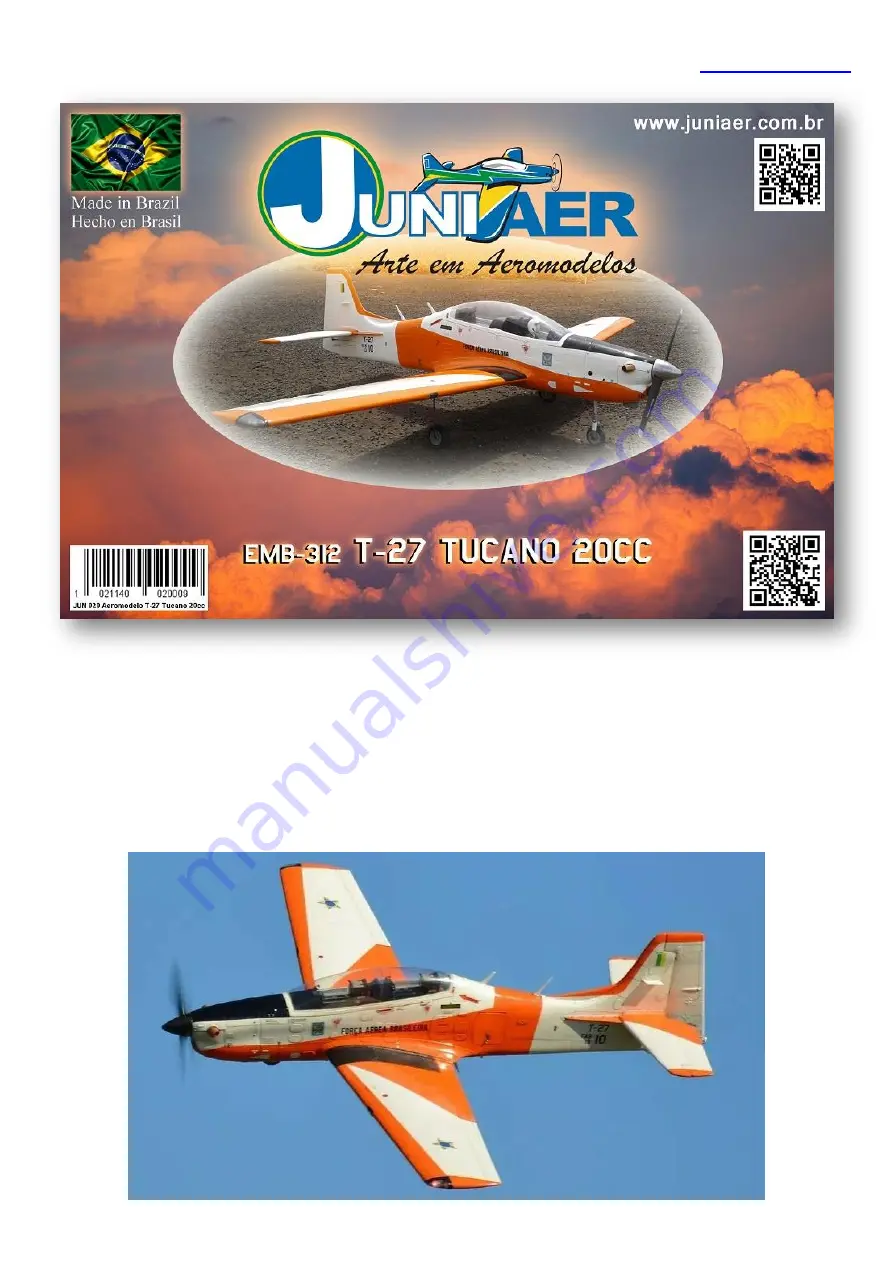

T-27 Tucano 20cc 1.2 2022

www.juniaer.com.br

1

A traditional 20cc sport/scale category model airplane!

Lots of incredible detail in this classic model airplane with scale, acrobatic and sport flight

capabilities, bringing precise and smooth performance for the intermediate to advanced level

model airplane pilot.