– 5 –

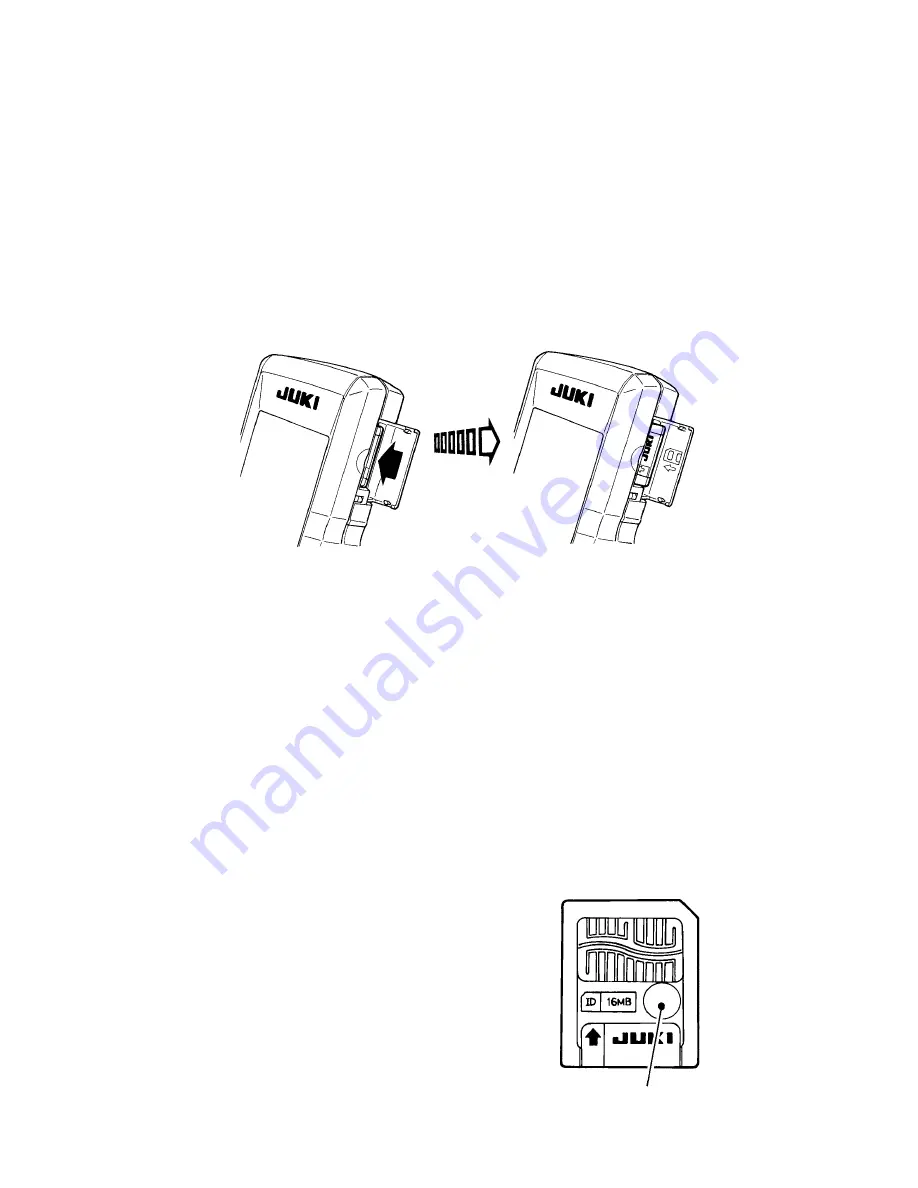

3) When the setting of the card is completed, close the smart media card cover. It is not possible

to receive or send the data with the smart media card with the cover opened. For the operating

procedure, refer to "USING COMMUNICATION FUNCTION of the Instruction Manual.

If the smart media card comes in contact with the cover and the cover is not closed, check the

following matters.

• Check that inserting is stopped in the state that the card protrudes by approximately 10 mm.

• Check that the coantact part is faced downward and inserted.

• Check that the smart media card other than 3.3V voltage type is used.

(2) Removing procedure

1) Open the smart media cover, press the card until it goes no further and reduce the force. The card

returns by approximately 10 mm by reversing order at the time of setting.

2) Then drawing up the card completes removing.

< Handling the smart media card >

• Smart media is a precision instrument. Do not bend or shock it.

• It is recommended to periodically save the data saved in the smart media into the other vehicle for the

accident.

• When initializing data, perform it after checking that there is no necessary data in the card. When the

data is initialized, the internal data is deleted.

• Avoid using or keeping the card in a high temperature or high humidity place.

• Avoid using the card near heating or combustible articles.

• When the contact part becomes dirty, contact failure will be caused. Control so that the card is not

touched by hand, or that dust, oil or other foreign material does not adhere to the card. Besides, be

careful of handling the card since the internal data is broken by the static electricity or the like.

• Smart media has the life, and writing and deletion cannot be performed after an extended period of

use. In this case, replace the smart media with a new one.

< Prevention of memory error >

• When write prohibition seal

1

is pasted, the card

becomes exclusive for reading and writing cannot

be performed.

• Strip off the seal when you desire to record

again.

• Do not use again the seal which was pasted once

and stripped off. The trouble of the main unit will

be caused.

< 3.3V type >

1