TO INSERT WELDING FILTER:

Remove the inner securing frame and

one of the two protective clear lenses from the faceshield. Insert the

welding filter, followed by the clear lens and securing frame, ensuring that

the inner frame clicks firmly into place.

FITTING

FOR HARNESS MOUNTED FACESHIELD:

The head height and size can be adjusted as follows:

1.

Slide left half of crown strap through loops on the right half to obtain

correct height, engage retaining pin in correct hole.

2.

Place faceshield on head and check height setting. Ensure headband

is not too low on brow. If necessary repeat step 1 until correct height

adjustment is achieved.

3.

With faceshield on head turn adjuster knob to obtain a firm and comfortable fit.

FITTING

FOR HELMET MOUNTED FACESHIELD:

The faceshield is designed to be fitted to most leading makes of industrial

safety helmet with standard size peak. Slide helmet peak into slot in the

faceshield. Stretch PVC covered retaining spring over the crown of the

helmet until it fits securely around the helmet shell.

USE:

The faceshield will only offer protection with a welding filter correctly

inserted and when the faceshield is in the lowered position. The welding

filter is marked with the appropriate shade grade. For proper selection of

the filter grade please consult the chart. Ensure that the correct welding

filter is fitted before commencing welding operations.

Toughened mineral filter oculars shall only be used in conjunction with a

suitable backing ocular.

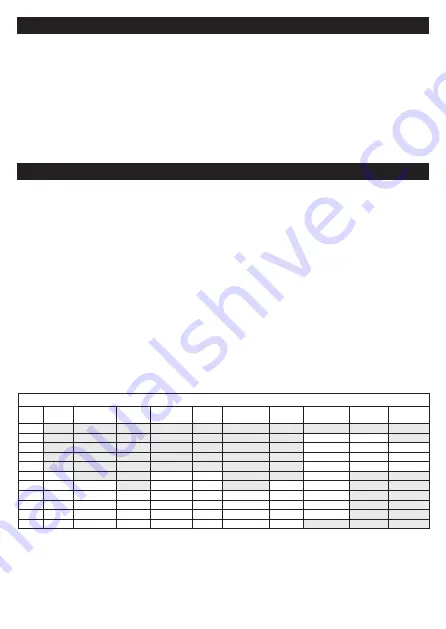

The scale number, given in the table below, is to be used for arc welding,

gas welding and arc gouging. The following abbreviations are used

according to ISO4063:

• MIG corresponds to Metal Arc Welding with Inert Gas Shield.

• MAG corresponds to Metal Arc Welding with Non-inert Gas Shield.

• TIG corresponds to Tungsten Inert Gas.

• Arc-Air Gouging corresponds to the use of a carbon electrode

and a compressed air jet to remove the molten metal.

The term ‘heavy metals’ applies to steels, alloy steels, copper and its

alloys, etc. The hatched areas correspond to the ranges where the welding

operations are not usually used in the current practice of manual welding.

Note:

If the use of filters selected from the table produces a feeling of

discomfort, the working environment and the eyesight of the operator

should be examined. It can be harmful to use filters with too high a scale

number (too dark) as this would force the operator to move too close to

the radiation source and to inhale harmful fumes. For work carried out

in the open air and strong natural light, it is possible to use a filter one

scale number higher.

In the table the letter A corresponds to the current rating of the welding

device in Amperes. The letters l/h correspond to the flow rate of the

acetylene gas in litres per hour.

Welding Process or Related Technique

Scale

Number

Covered

Electrode

MIG with

heavy metals

MIG

light alloys

TIG on all

metals/alloys

MAG

Air-arc gouging

Plasma jet

cutting

Microlasma arc

welding

Gas welding Gas cutting

3

4

1.5-6A

<70l/h

5

6-15A

70-200l/h

900-2000l/h

6

15-40A

200-800l/h 2000-4000l/h

7

40-60A

>800l/h

4000-8000l/h

8

<60A

10-30A

<70A

60-100A

9

60-100A

70-125A

30-70A

70-100A

100-125A

100-125A

10

100-150A 125-175A

125-175A

70-125A

100-150A

<175A

125-150A

125-175A

11

150-200A 175-250A

175-225A

125-200A 150-225A

175-200A

150-175A

175-225A

12

200-300A 250-350A

225-300A

200-300A 225-400A

200-250A

175-250A

225-325A

13

300-450A 350-450A

300-400A

300-350A 400-600A

250-350A

250-400A

IMPORTANT NOTE:

This table is for guidance only. It is the USERS responsibility to ensure that Protective Equipment is suitable and adequate for use

in the intended hazardous environment.

FITTING & USING WELDING FACESHIELD

VISOR REPLACEMENT:

Scratched or damaged visors should be replaced. Replacement visors are

available for all faceshields. Under normal circumstances the faceshield and

visor should offer adequate protection for 2–3 years.

I

NVINCIBLE & CLIPTITE:

1.

Pull visor off press-studs at each end.

2.

Disengage visor from centre peg.

3.

Reverse procedure to fit new visor.

FACESAVER & MARTCARE:

1. Push out and retain stud securing visor to browguard.

2.

Swing visor down and disengage visor keyhole slots from either side of browguard.

3.

Reverse procedure to fit new visor

SUREFIT™:

1.

To remove the old visor, press the top of it inwards so it comes away from

pip and pull down. Repeat for other two pips.

2.

Locate the new visor into the channel around the rim of the visor carrier.

3.

Push the centre of the visor inwards in order to locate the central hole over

the central pip of the visor carrier.

4.

Ensuring the visor is located in the channel on the relevant side locate the

remaining two pips.

LITEGUARD™:

1. To remove the old visor, press the top of it inwards so it comes away from notch.

2. Swing visor down and disengage visor keyhole slots from either side of browguard.

3. Reverse procedure to fit new visor.

VISOR REPLACEMENT FOR CLEAR & WIRE GAUZE VISORS