24

SERVICE AND ADJUSTMENTS

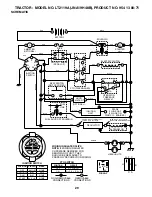

FIG. 30

HEX

BOLT

KEPS NUT

POSITIVE

(RED)

CABLE

NEGATIVE

(BLACK)

CABLE

TERMINAL

GUARD

TERMINAL

ACCESS

DOOR

TO REPLACE HEADLIGHT BULB

• Raise hood.

• Pull bulb holder out of the hole in the backside of the

grill.

• Replace bulb in holder and push bulb holder securely

back into the hole in the backside of the grill.

• Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your tractor to run

poorly, stop running, or prevent it from starting.

• Check wiring. See electrical wiring diagram in the

Repair Parts section.

TO REPLACE FUSE

Replace with 20 amp automotive-type plug-in fuse. The

fuse holder is located behind the dash.

REPLACING BATTERY (See Fig. 30)

WARNING: Do not short battery ter-

mi nals by allowing a wrench or any other

object to contact both terminals at the

same time. Before connecting battery,

remove metal bracelets, wristwatch

bands,rings,etc.

Positive terminal must be connected

fi rst to prevent sparking from ac ci den tal

grounding.

• Lift hood to raised position.

• Remove terminal guard.

• Disconnect BLACK battery cable then RED battery

cable and carefully remove battery from tractor.

• Install new battery with terminals in same position as

old battery.

• Reinstall terminal guard.

• First connect RED battery cable to positive (+) battery

terminal with hex bolt and keps nut as shown. Tighten

securely.

• Connect BLACK grounding cable to negative (-) bat tery

terminal with remaining hex bolt and keps nut. Tighten

securely

• Close terminal access doors.

• Close hood.

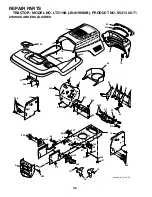

FIG. 29

FIG. 28

RE TAIN ING

RING

WASH ERS

SQUARE KEY (REAR

WHEEL ONLY)

AXLE

COVER

WEAK OR DEAD

BATTERY

FULLY CHARGED

BATTERY

TO START ENGINE WITH A WEAK BAT TERY

(See Fig. 29)

WARNING

:

Lead-acid batteries gen-

er ate ex plo sive gases. Keep sparks,

fl ame and smoking ma te ri als away from

bat ter ies. Always wear eye pro tec tion

when around batteries.

If your battery is too weak to start the engine, it should be

recharged. (See "BATTERY" in the Maintenance sec tion

of this man u al).

If “jumper ca bles” are used for emer gen cy starting, follow

this pro ce dure:

IMPORTANT

: YOUR TRACTOR IS EQUIPPED WITH A 12 VOLT

SYSTEM. THE OTHER VEHICLE MUST ALSO BE A 12 VOLT

SYSTEM. DO NOT USE YOUR TRACTOR BATTERY TO START

OTHER VEHICLES.

TO ATTACH JUMPER CABLES -

• Connect one end of the RED cable to the POSITIVE

(+) terminal of each battery(A-B), taking care not to

short against tractor chassis.

• Connect one end of the BLACK ca ble to the NEGA TIVE

(-) terminal (C) of fully charged battery.

• Connect the other end of the BLACK cable (D) to good

chassis ground, away from fuel tank and bat tery.

TO REMOVE CABLES, REVERSE ORDER -

• BLACK cable fi rst from chassis and then from the fully

charged battery.

• RED cable last from both batteries.

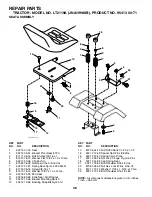

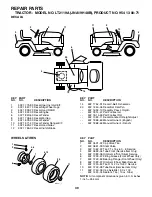

Summary of Contents for JNA19H48B

Page 46: ...46 SERVICE NOTES ...

Page 48: ...00949 jonsered ...