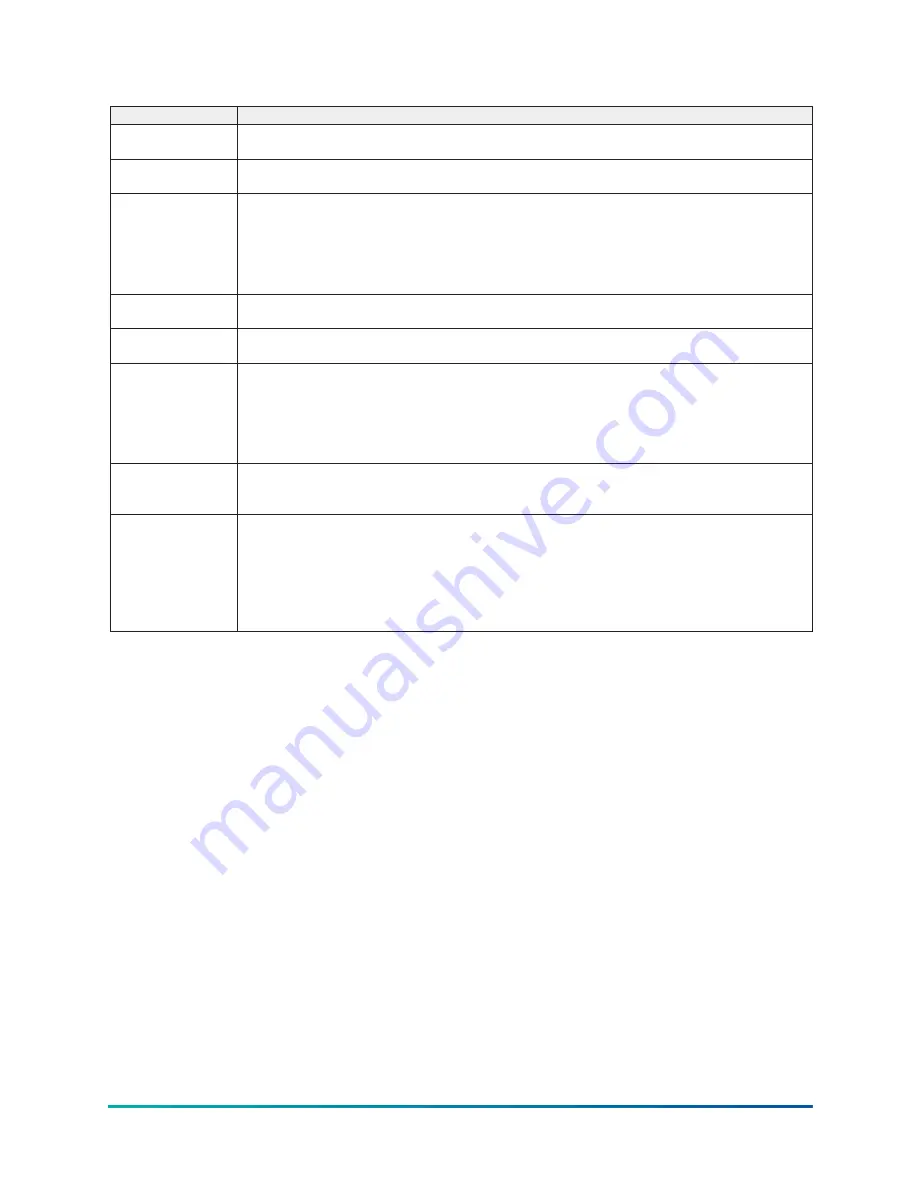

Table 92: Safety shutdown messages

Message

Description

VSD – PHASE B

INPUT DCCT

See the previous message,

VSD – PHASE C

INPUT DCCT

See the previous message,

VSD – PHASE A

MOTOR DCCT

The motor current in each phase of the drive is measured at the beginning of the run command. The

motor current at this time should measure very low. This low value is used as the zero current value

for the rest of this run time. The motor current is then monitored for the next 1.5 seconds to ensure

that a minimum amount of current is flowing to the motor. After 1.5 seconds, if the motor current is

less than 25 A on any phase, then this shutdown is generated. When the condition clears, the chiller

can be started after the Clear Faults button is pressed.

VSD – PHASE B

MOTOR DCCT

See the previous message,

.

VSD – PHASE C

MOTOR DCCT

See the previous message,

.

VSD – PRECHARGE

LOCKOUT

If the drive fails to complete pre-charge due to

VSD – PRECHARGE – LOW DC BUS VOLTAGE 1

or

VSD – PRECHARGE – LOW DC BUS VOLTAGE 2

, the drive starts a 10 second timer before clearing

the fault and allowing another pre-charge to start. The drive’s cooling fan(s) and water pump(s)

remain energized during this time. The drive allows up to three consecutive pre-charge-related faults

to occur. After the third consecutive pre-charge-related fault, this shutdown is generated. When the

condition clears, the chiller can be started after the Clear Faults button is pressed.

VSD – RECTIFIER

PROGRAM FAULT

The drive software contains a verification process to ensure that the correct set of software is

installed in the drive logic board for the application. When this condition clears, the chiller can be

started after the Clear Faults button is pressed.

VSD SHUTDOWN –

REQUESTING FAULT

DATA

The drive has shut down the chiller and the control center has not yet received the cause of the fault

from the drive from the serial communications link. The drive shuts down the chiller by opening

the motor controller VSD Stop Contacts, which is located on the drive logic board and connected

between TB6-16 and TB6-53 in the control center. The Microboard in the control center then sends a

request for the cause of the fault to the drive logic board over the serial communications link. Serial

communications are initiated every 2 seconds. This message is generally displayed for a few seconds

and then replaced with one of the other drive fault messages.

YVAM Control Center

110

Summary of Contents for YORK YVAM 0350

Page 2: ...2 YVAM Control Center...

Page 10: ...Figure 4 Variable speed drive nomenclature YVAM Control Center 10...

Page 15: ...Figure 8 System piping and instrumentation diagram P ID 15 YVAM Control Center...

Page 154: ...Figure 62 Sample printout status or history YVAM Control Center 154...

Page 155: ...Figure 63 Sample printout status or history continued 155 YVAM Control Center...

Page 156: ...Figure 64 Sample printout setpoints YVAM Control Center 156...

Page 157: ...Figure 65 Sample printout setpoints continued 157 YVAM Control Center...

Page 158: ...Figure 66 Sample printout schedule YVAM Control Center 158...

Page 159: ...Figure 67 Sample printout sales order 159 YVAM Control Center...

Page 160: ...Figure 68 Sample printout security log report YVAM Control Center 160...