JOHNSON CONTROLS

19

SECTION 2 - INSTALLATION

FORM 160.78-N1

ISSUE DATE: 5/30/2012

2

MAKE CONNECTIONS

After the unit is leveled, place wedges and/or shims un-

der each corner to solidly support the unit in this position

while connecting and hanging the piping, adjusting the

connections, and checking for proper alignment.

After the connections are made and insulation is applied,

the unit can be filled with water and checked for leaks.

If spring isolators were installed, final adjustments

can be made to the leveling bolts until the wedges and

shims can be removed. The unit should now be in cor-

rect level position, clear of the floor or foundation and

without any effect from the weight of the piping.

The coolant temperature inside any JCI-supplied liq-

uid-cooled motor starter must be maintained above the

dewpoint temperature in the equipment room to prevent

condensing water vapor inside the starter cabinet. There-

fore, an additional temperature-controlled throttle valve

is needed in the flow path for the starter heat exchanger

to regulate cooling above the equipment room dewpoint

for applications using cooling sources other than evapo-

rative air-exchange methods, such as wells, bodies of

water, and chilled water. The temperature control valve

should be the type to open on increasing drive coolant

temperature, fail-closed, and set for a temperature above

dewpoint. It can be requested as factory-supplied on a

chiller order by special quotation.

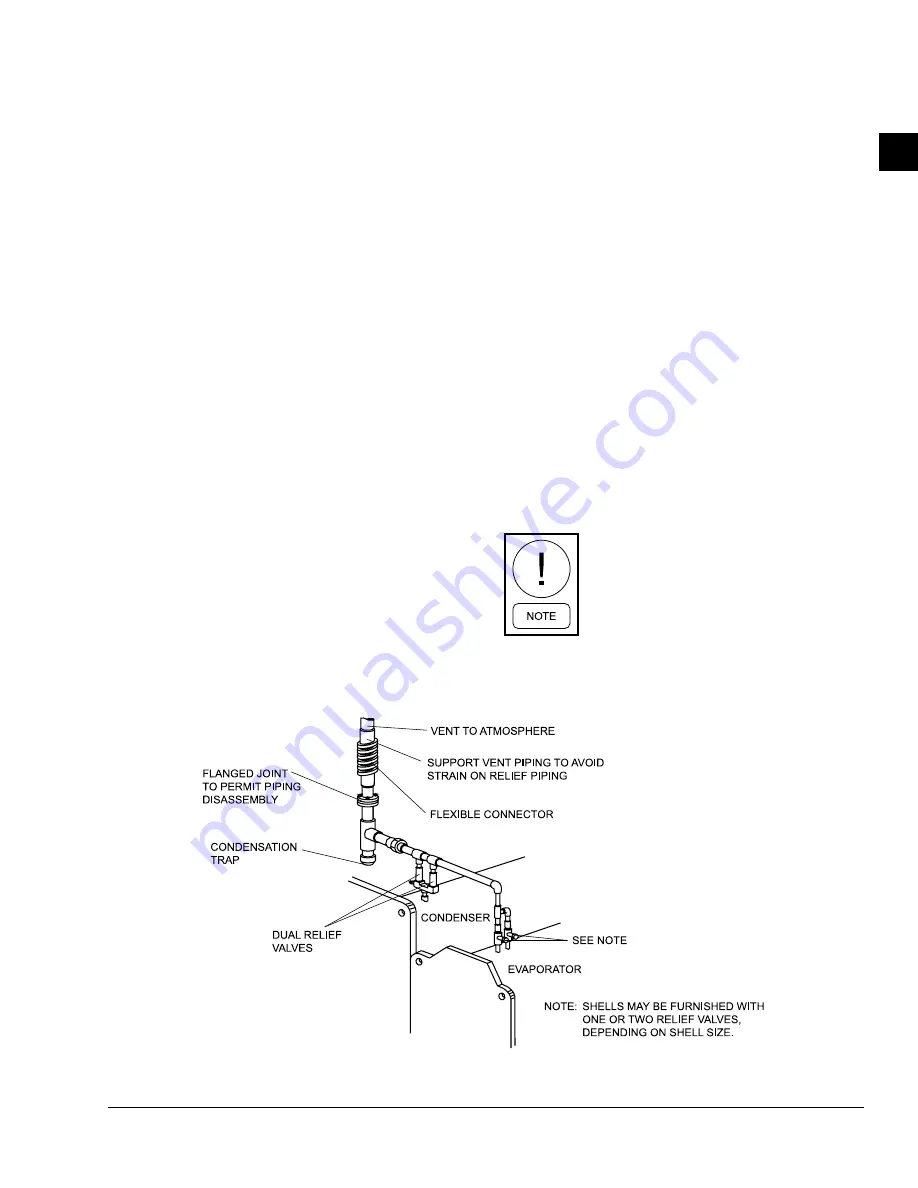

Piping Connections

After the unit is leveled (and wedged in place for op-

tional spring isolators) the piping connections may be

made; chilled water, condenser water and refrigerant

relief. The piping should be arranged with offsets for

flexibility, and adequately supported and braced inde-

pendently of the unit to avoid strain on the unit and vi-

bration transmission (refer to

Figure 7

). Hangers must

allow for alignment of pipe. Isolators (by others) in the

piping and hangers are highly desirable, and may be re-

quired by specifications, in order to effectively utilize

the vibration isolation characteristics of the vibration

isolation mounts of the unit.

Check for piping alignment – Upon completion of pip-

ing, a connection in each line as close to the unit as

possible should be opened, by removing the flange

bolts or coupling and checked for piping alignment. If

any of the bolts are bound in their holes, or if the con-

nection springs are out of alignment, the misalignment

must be corrected by properly supporting the piping or

by applying heat to anneal the pipe.

If the piping is annealed to relieve stress,

the inside of the pipe must be cleaned of

scale before it is finally bolted in place.

FIGURE 7 -

TYPICAL REFRIGERANT VENT PIPING

LD03863