JOHNSON CONTROLS

43

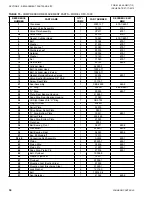

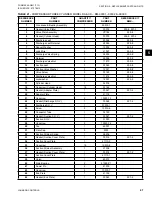

SECTION 5 - REPLACEMENT PARTS AND KITS

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

5

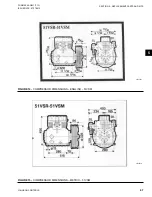

VACUUM PUMP – MODEL CRR-1

Gurgling Noise

The vacuum pump will gurgle to varying degrees un-

der three different conditions of performance:

1. When operating at high pressure as in the begin-

ning of the evacuation cycle.

2. When the oil level in the pump is low.

3. When a large leak is present in the system being

evacuated.

Suction and Discharge Pressure Problems

Leakage, oil contamination, V-belt slippage and low

oil level are four major causes of insufficient suction

or dis charge pressure. If the recovery and/or recycle

system is free from leaks, and unwarranted suction

problems still exist, the pump should be checked. A

simple criterion for the condition of the vacuum pump

is a determination of its ulti mate pressure capability. If

the suction obtainable is very poor, the pump may be

badly contaminated, low on oil or malfunctioning. On

the other hand, if the pressure is only slightly higher

than the guaranteed ultimate pressure of the pump, an

oil change may be all that is required.

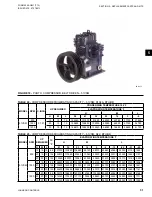

FIGURE 12 -

VACUUM PUMP REPLACEMENT PARTS – MODEL CRR-1

LD01114

If the recovery and/or recycle system is free from leaks

and sufficient suction exists, but the discharge pressure

is insuf ficient, there are several sources to the problem.

A simple explanation, there is an insufficient flow of

refrigerant vapor into the vacuum pump. Check to see

that the tubing con necting the suction port to the chiller

is not obstructed. A low oil level or V-belt slippage can

cause the same symp toms. If there is a leak in the oil

case of the vacuum pump, this can also cause insuffi-

cient discharge pressure. If none of these explanations

fit the observations, the pump may be malfunctioning

and should be sent back to a repair facility.

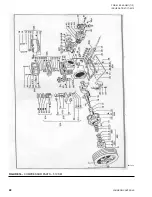

SHAFT SEAL REPLACEMENT

To replace the shaft seal of a pump, drain the oil and

remove the pump pulley and key. Remove the screws

securing the old seal and pry it loose with a screw-

driver or similar wedge, being careful not to mar the

surface of the pump body against which the seal fits.

Discard the seal and its gasket, inspect all surfaces and

repair any damages with a fine abra sive stone. Wipe all

sealing areas clean and place a film of DuoSeal oil on

both the shaft and the inside bore of the new shaft seal.

Using a new gasket, carefully slide the new seal into

position and center it on the shaft. It is not necessary to

apply any sealant to the gasket. Tighten the mounting

screws uniformly and refill the pump with DuoSeal oil.

Follow instructions included in repair kit.