420705-UIM-C-0310

10

Johnson Controls Unitary Products

SECTION IV: GAS PIPING

GAS SAFETY

GAS PIPING INSTALLATION

Properly sized wrought iron, approved flexible or steel pipe must be

used when making gas connections to the unit. If local codes allow the

use of a flexible gas appliance connection, always use a new listed con-

nector. Do not use a connector that has previously serviced another gas

appliance.

Some utility companies or local codes require pipe sizes larger than the

minimum sizes listed in these instructions and in the codes. The furnace

rating plate and the instructions in this section specify the type of gas

approved for this furnace - only use those approved gases. The instal-

lation of a drip leg and ground union is required. Refer to Figure 15.

The furnace must be isolated from the gas supply piping system by

closing its individual external manual shutoff valve during any pressure

testing of the gas supply piping system at pressures equal to or less

than 1/2 psig (3.5 kPa).

Gas piping may be connected from either side of the furnace using any

of the gas pipe entry knockouts on both sides of the furnace. Refer to

Figure 12.

GAS ORIFICE CONVERSION FOR PROPANE (LP)

This furnace is constructed at the factory for natural gas-fired operation,

but may be converted to operate on propane (LP) gas by using a fac-

tory-supplied LP conversion kit.

1.

Shut off gas supply at valve upstream from furnace or at meter as

required.

2.

Disconnect gas supply piping from gas valve on furnace.

3.

Disconnect electrical wires from gas valve, noting which wires are

connected to which terminals

4.

Remove the screws that attach the gas manifold to the burner sup-

port box.

5.

Remove and discard natural gas orifices.

Plan your gas supply before determining the correct gas pipe entry.

Use 90-degree service elbow(s), or short nipples and conventional

90-degree elbow(s) to enter through the cabinet access holes.

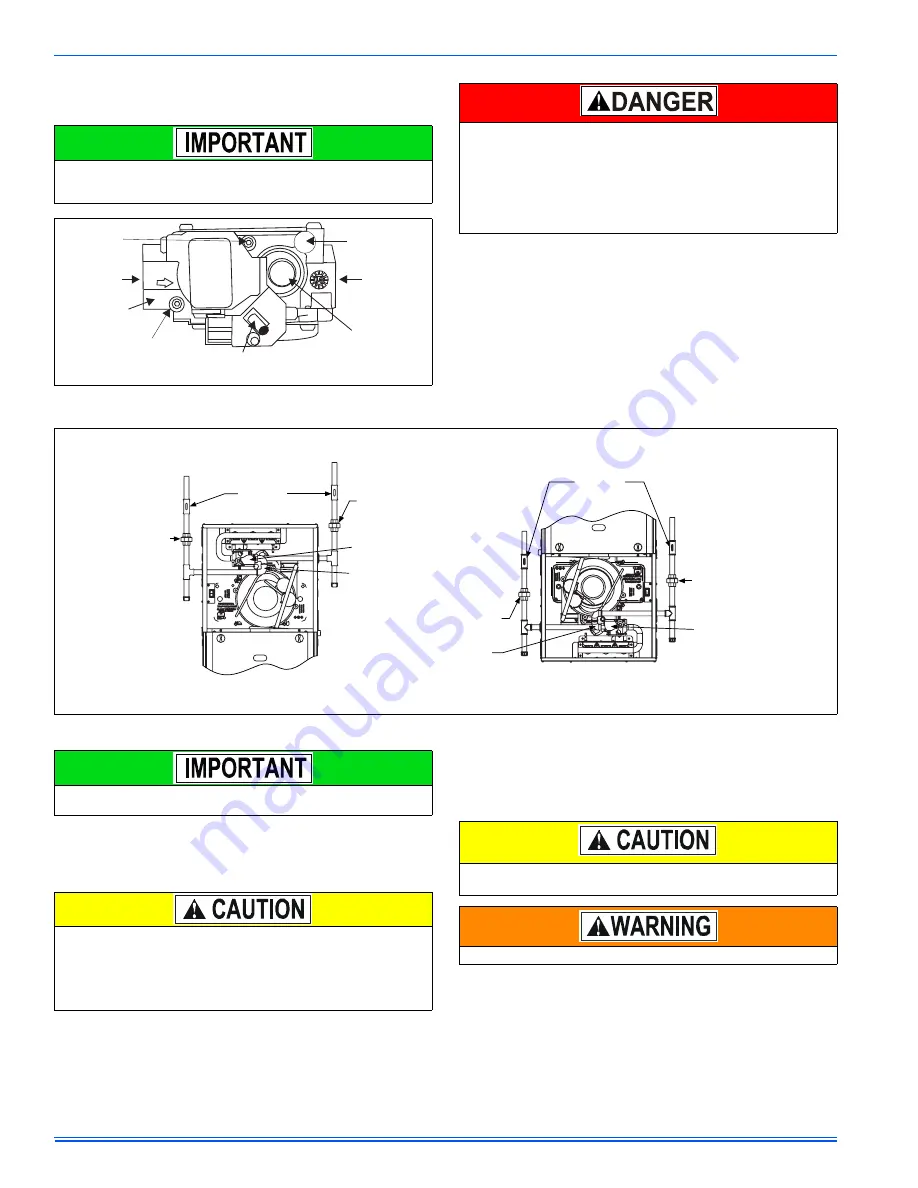

FIGURE 14:

Gas Valve

INLET

WRENCH

BOSS

INLET

PRESSURE

PORT

ON

OFF

ON/OFF SWITCH

(Shown in ON position)

MAIN REGULATOR

ADJUSTMENT

OUTLET

OUTLET

PRESSURE

PORT

VENT PORT

An overpressure protection device, such as a pressure regulator,

must be installed in the gas piping system upstream of the furnace

and must act to limit the downstream pressure to the gas valve so it

does not exceed 0.5 PSI (14" w.c. (3.48 kPa). Pressures exceeding

0.5 PSI (14” w.c. (3.48 kPa) at the gas valve will cause damage to

the gas valve, resulting in a fire or explosion or cause damage to

the furnace or some of its components that will result in property

damage and loss of life.

FIGURE 15:

Upflow/Downflow Gas Piping

Upflow

Configuration

Downflow

Configuration

External

Manual

Shut-off

Valve

External

Manual

Shut-off

Valve

To Gas

Supply

To Gas

Supply

To Gas

Supply

To Gas

Supply

Drip

Leg

Drip

Leg

Drip

Leg

Drip

Leg

Gas

Pipe

Gas

Valve

Gas

Pipe

Gas

Valve

Ground

Union

Ground

Union

Ground

Union

Ground

Union

NOTE: Ground Union maybe installed inside or outside unit.

An accessible manual shutoff valve must be installed upstream of

the furnace gas controls and within 6 feet (1.8 m) of the furnace.

The gas valve body is a very thin casting that cannot take any

external pressure. Never apply a pipe wrench to the body of the gas

valve when installing piping. A wrench must be placed on the octa-

gon hub located on the gas inlet side of the valve. Placing a wrench

to the body of the gas valve will damage the valve causing improper

operation and/or the valve to leak.

The gas supply must be shut off prior to disconnecting the elec-

trical power, before proceeding with the conversion.

SHOCK HAZARD - Turn off electrical supply to furnace.