F61 Series Standard Flow Switches Installation Instructions

3

Mounting

!

CAUTION: Risk of Equipment Damage.

To avoid damaging the switch, do not tighten the

switch to the tee by grasping the switch enclosure.

Use only the wrench flats provided.

Mount the F61 Series Flow Switch, using the following

guidelines:

•

Install the switch so that the cover and interior are

accessible.

•

Mount the switch so that the flow of fluid is in the

direction of the arrow on the switch casing.

•

Use a pipe union on each side of the flow switch to

allow easy removal or replacement.

•

Mount the switch so that the pipe does not extend

too far into the flow switch casing.

•

Use pipe thread sealer on male threads only.

•

Do not remove the cover gasket or the wire

grommet from the conduit opening.

For 1 in. pipe installation, mount the F61 flow switch in

a standard 1 in. x 1 in. x 1 in. tee. For larger sizes of

pipe, use a reducing tee to keep the flow switch close

to the pipe and provide adequate paddle length in the

flow stream.

Example: Use a 2 in. x 2 in. x 1 in. tee for a

2 in. pipe. If a standard 2 in. x 2 in. x 2 in. tee is

used, install a face or hex bushing in the top

opening to reduce it to 1 in.

Mount the flow switch so the terminals or wire leads

are easily accessible for wiring. Screw the flow switch

in position so the flat of the paddle is at a right angle to

the flow. The arrow on the side of the case must point

in the direction of the flow.

Location Considerations

Mount the F61 flow switch in a horizontal pipeline or a

vertical pipeline with upward fluid flow. Do not use in a

vertical pipeline with downward flow. When mounted in

a vertical pipe with upward flow, the switch trips at a

slightly higher flow than shown in Table 3 through

Table 6

,

due to the effect of gravity on the switch

mechanism.

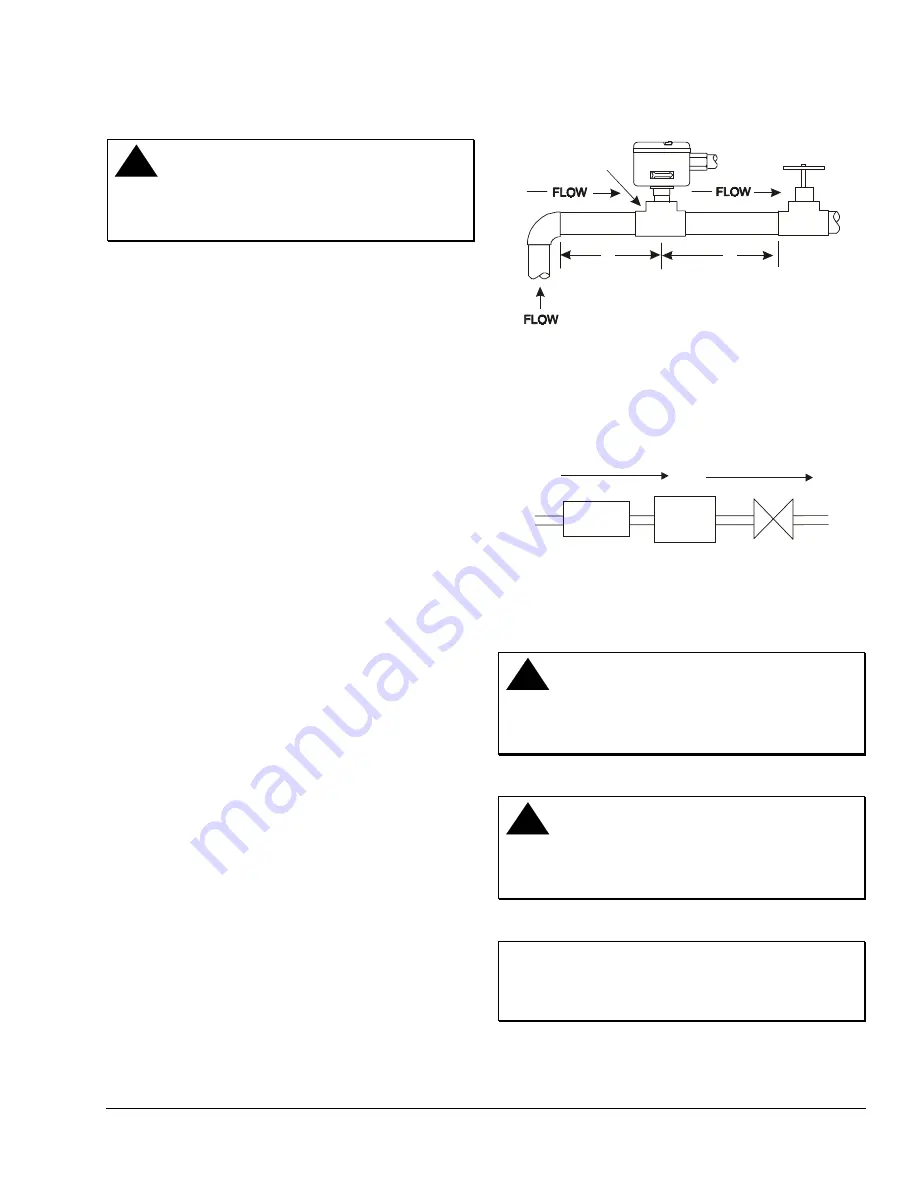

Mount the F61 flow switch in a section of pipe where

there is a straight run of at least five pipe diameters on

each side of the flow switch from the nearest elbow,

valve, or other pipe restriction. See Figure 5.

Dimension must be at least

five pipe diameters from the nearest

elbow, valve, or other pipe restriction.

A

A

A

Tee or Welded

Half-coupling

Figure 5: Required Piping Distance

Do not subject the flow switches to water hammer.

Use a suitable water hammer arrester if a fast-closing

valve is located downstream of the flow switch. See

Figure 6.

Flow

Switch

Water

Hammer

Arrester

Valve

Flow

Figure 6: Water Hammer Arrester Location

Schematic

Wiring

!

WARNING: Risk of Electrical Shock.

Disconnect power supply before making electrical

connections. Failure to follow this precaution may

result in electrical shock or death.

!

CAUTION: Risk of Equipment Damage.

Using terminal screws other than those provided will

void the warranty and may damage the switch. Use

only the terminal screws furnished.

IMPORTANT:

To prevent moisture from entering

and condensate from forming inside the NEMA 3R

enclosure, do not remove the cover gasket or the

wire grommet from the conduit opening.