4

Refrigerant Coils

Refrigerant coils should be kept clean to maintain max-

imum performance. If fins become dirty, clean with

cold water and detergent, or one of the commercially

available chemical coil cleaners. Rinse coils thorough-

ly after cleaning.

1. Follow steps 1-4 from Steam and Water Coil

cleaning procedure preceding.

2. Mix a high quality coil cleaning detergent with

water accordance to the manufacturer’s instruc-

tions. If the detergent is strongly alkaline after

mixing (pH 8.5 or higher), it must contain an in-

hibitor. Carefully follow the detergent manufac-

tures instructions on the use of the product.

3. Place the mixed solution in a garden sprayer or

high-pressure sprayer. If a high pressure sprayer

is used note the following:

•

Maintain a minimum nozzle spray angle of

15 degrees.

•

Spray perpendicular to the coil face.

•

Protect other areas of the air handler and in-

ternal controls from contact with moisture or

the cleaning solution.

•

Keep the nozzle at least 6 inches from the

coil.

•

Do not exceed 600 psi.

4.

Spray the leaving airside of the coil first, then the

entering airside. Use a block-off to prevent spray

from going through the coil and into dry sections

of the unit and/or system ductwork. Carefully fol-

low the cleaning solution manufacturer’s usage

instructions.

5. Thoroughly rinse both sides of the coil and the

drain pan with cool, clean water.

6. Repeat steps 4 and 5 as necessary.

7.

Straighten any coil fins that may have been dam

-

aged during the cleaning process with a fin comb.

8.

Confirm that the drain line remains open follow

-

ing the cleaning process.

9. Replace all panels and parts and restore electrical

power to the unit.

10. Use caution to assure that any contaminated ma-

terial does not contact other areas of the unit or

building.

Properly dispose of all contaminated ma-

terials and cleaning solutions.

Winterizing Water Coils

Due to air stratification, failure of outdoor air damp-

ers and/or preheat controls, coil freeze-up can occur.

Scheduled draining of water cooling coils for win-

ter shutdown cannot be depended upon as insurance

against interior tube freezeup. Freeze-up will result in

severe coil damage. It is recommended that all coils be

drained as thoroughly as possible and then treated in

the following manner.

Fill each coil independently with an anti-freeze solu-

tion using a small circulating pump and again thor-

oughly drain. Check freezing point of anti-freeze be-

fore proceeding to next coil. Due to a small amount of

water always remaining in each coil, there will be a di-

luting effect. The small amount of anti-freeze solution

remaining in coil must always be sufficient enough to

prevent freeze-up.

Carefully read instructions for mixing

anti-freeze solution used. Some products

will have a higher freezing point in its

natural state than when mixed with water.

The freezing of coils is not the responsibil-

ity of ENVIRO-TEC®.

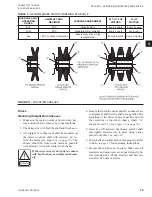

OPERATING GUIDELINES

Operating Limits

Do not exceed the operating limits in

. A fan wheel that is operated beyond the rpm and

temperature limits shown may suffer permanent distor-

tion or failure.

Vibration Levels

Each unit that is shipped has been trim-balanced to

function properly. Although the factory requirements

are much tighter, to assure satisfactory operation after

enduring the rigors of shipping and installation. The

following is accepted industry guidelines for field-bal-

.

JOHNSON CONTROLS

29

SECTION 4 - PERIODIC MANINTENANCE AND SERVICE

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013