LD14010

SHEAVE

CENTER

LINES

BELT CENTER

LINES

A

A

FIGURE 12 -

SHEAVE ALIGNMENT

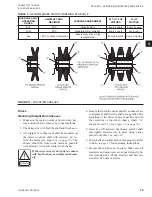

Mounting Split Tapper Sheaves

1. Make sure there are no nicks or burrs on the key,

keyway, and shaft. If so, remove by proper meth-

ods.

2. Remove any oils, lubricants or contaminants from

the bushing, capscrew, and tapered bore.

3. Check key size with both the bushing and the

shaft.

4. Put bushing (B) loosely in hub of sheave (A).

Do not press tight onto drive. Start capscrew (C)

by hand, turning them just enough to engage the

threads in the tapered holes on hub. Do not use

wrench at this time. The bushing should be loose

enough in the hub to move slightly.

5. Slide assembly on to shaft making allowance for

endplay of shaft to prevent rubbing. Do not force

assembly on shaft. If it does not go on easily,

check shaft, bushing, and key size.

6. Be sure that both the driver and driven sheaves are

in alignment and that the shafts are parallel. The

centerline of the driver sheave must line up with

the centerline of the driven sheave. Angle “A”

7. Insert key (D) between the sheave and the shaft.

8. Tighten capscrews progressively with wrench.

Dothis following a star pattern, taking a partial

turn on each capscrew successively until all are

for proper torque).

Do not attempt to pull flange flush with

hub - some gap should remain between

flange and hub after tightening.

FIGURE 13 -

SPLIT TAPPER SHEAVE MOUNTING

9. Put on belt and adjust belt tension properly.

Refer

to Belt Section for tensioning instructions.

10. Be sure that all keys are in place. Be sure that all

setscrews and capscrews are torqued properly be-

fore starting drive. Check setscrews and belt ten-

sion after 24 hours of service.

Adjust Variable Pitched Sheaves

(Provided on motor only). See

1. Slack off all belt tension by moving motor towards

blower shaft until belts are free of groove(s). For

easiest adjustment, remove belts from groove(s).

2. Loosen setscrew (B) in outer locking ring.

3. Loosen but do not remove capscrew.

4. Remove key (D).

This key projects a small amount to pro-

vide a grip for removal.

5. Adjust pitch diameter by opening or closing the

movable flange(s) by a half or full turn. Opening

the flange(s) will decrease the blower speed, clos

-

ing the flange(s) will increase blower speed.

JOHNSON CONTROLS

26

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013

SECTION 4 - PERIODIC MANINTENANCE AND SERVICE