Suspending Using Field Supplied Supports

All field supplied structural supports must be designed

to support entire unit weight including all appurtenanc-

es, motor, drives, and all live or dead loads. All sup-

ports must be designed to meet applicable local codes

and ordinances. Each module must be supported with

an angle iron or channel. The angle iron or channel

must cover the width and length of the equipment base

and must be designed to mechanically lock the unit to

).

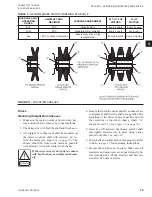

Internal Isolation

Equipment may be supplied with internal spring isola-

tion. If so, removal of shipping hold-downs is required

before equipment start-up (see

).

LD14007

SHIPPING HOLD-DOWNS-

REMOVE BEFORE START-UP

EXTRA HOLD-DOWN

ON SIZES 10 & ABOVE

FIGURE 8 -

REMOVE HOLD DOWNS

External Isolation

Install vibration isolators (see

in accordance with the job specifications and the in-

structions of the isolator manufacturer base. Base rails

are required for external isolation. If the coil module

is also isolated, the piping must be isolated or have a

flexible connection to prevent coil header damage due

to equipment movement. All piping, wiring, ductwork

and external connections must be isolated.

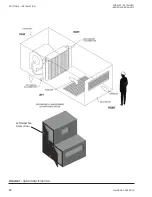

Service Clearance

Access to at least one side of the equipment is required

for routine service, maintenance and repair. Consider-

ation should be given to fan shaft, coil, filter removal,

motor, fan, bearings, and damper linkage access. Clear-

ance must meet or exceed applicable local and national

codes.

Panel Removal

To remove access panels, loosen the four retaining

screws and lift panel off. Alternately, lift off hinges

with quick turn fasteners.

General Piping

All pipe connections need to be supported indepen-

dently from the header. Failure to do so may cause

cracking at the headers. All piping shall be in accor-

dance with local codes and follow accepted industry

standards. DX coil distributor cap for test and nitrogen

charge must be removed before mounting TXV. All

coil connections are stubbed out of cabinet panel with

the exception of refrigerant (DX) coils. Field penetra-

tion of panels is required for liquid line piping.

FIGURE 9 -

ISOLATOR INSTALLATION

JOHNSON CONTROLS

15

SECTION 2 - INSTALLATION

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013

2