E-Link Gateway Installation Instructions

3

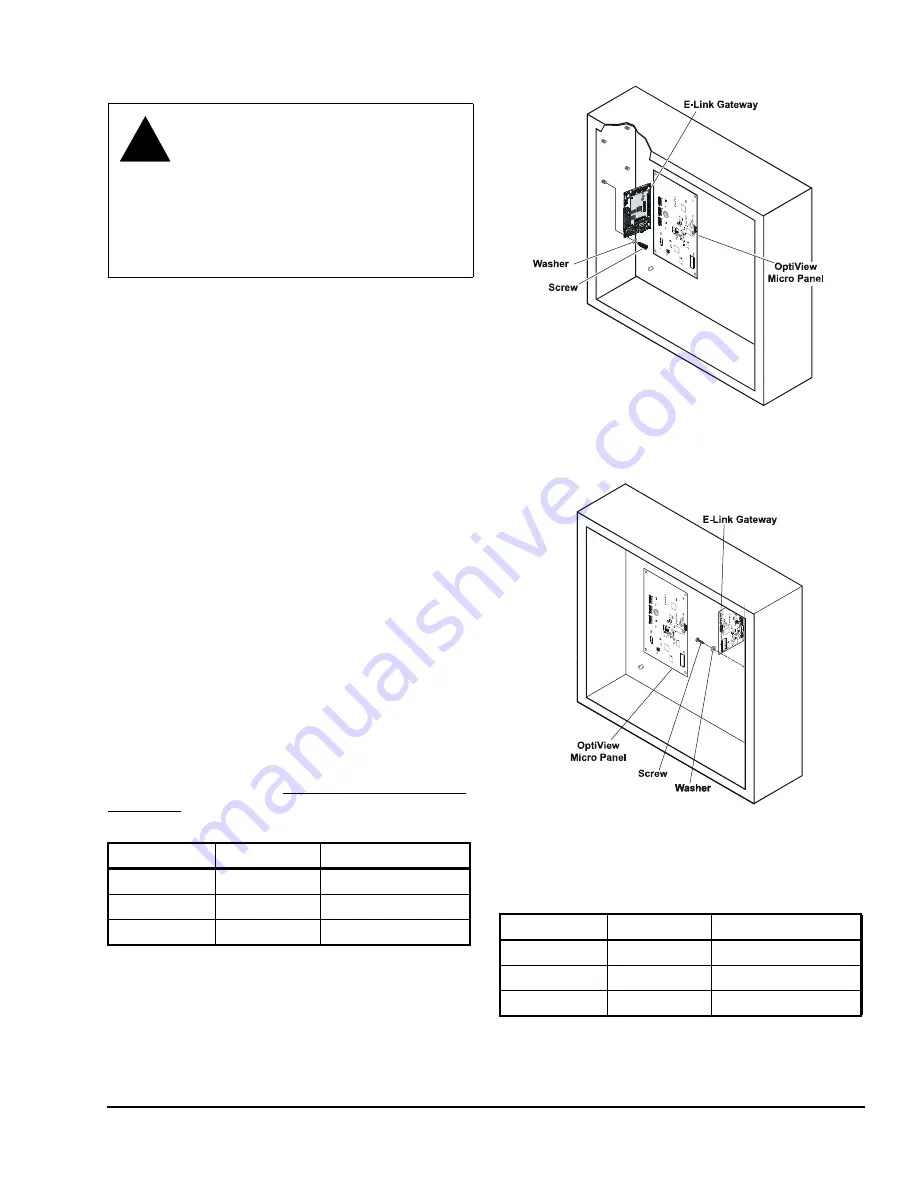

Mounting

OptiView Panel Installation

1.

Attach the E-Link Gateway board to the studs

provided inside the chiller enclosure (Figure 1 or

Figure 2), using the four screws and washers

provided in the OptiView/Latitude installation kit.

2.

Connect the communications cable (included with

the kit) from Port 2B on the E-Link Gateway to J2

on the OptiView Micro Panel. Ensure that wires are

connected according to Table 3.

3.

Check for stray wire strands, which could cause

short circuits, and ensure all components are

secure.

4.

Connect the BAS network to Port 1 (if the protocols

are transported by RS-485) or Port 4 (if the BAS

network is L

ON

W

ORKS

).

Note:

For RS-485 2-wire operation, connect a 100

ohm 1 W resistor between COM and the E-Link

Gateway’s TB5 COM (see Figure 24).

5.

Ensure jumper JP27 is set for RS-232 (see

Figure 20).

6.

Connect the power harness (included with the kit)

from J2 on the E-Link Gateway to J21 on the

Optiview Micro Panel (see Figure 20).

The E-Link Gateway is now ready to be configured

using Quick Start; see the

section in this document.

!

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnect or isolation

may be required to completely de-

energize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

Table 3: OptiView Wiring - E-Link Port 2B

E-Link Port 2B

OptiView Port

Wire Color

RX

GTX

Black

TX

GRX

Red

REF

N/A

Shield/Drain

Table 4: BAS Wiring - E-Link Port 1

E-Link Port 1

BAS

Wire Color

+

+

White

-

-

Blue

REF

REF

Black

FI

G

:Op

ti

_

P

n

l

Figure 1: OptiView Micro Panel Connected to

E-Link Gateway

FI

G:

Op

ti

_

P

nl

1

Figure 2: OptiView Micro Panel for YMC

2

Connected to E-Link Gateway