C-9500 Product Bulletin 3

Differential Adjustment

1.

Loosen the locknut.

2.

Using a screwdriver, slowly

rotate the differential

adjusting screw clockwise to

increase or

counterclockwise to

decrease the differential.

Turn the screw

approximately 1/8 of a turn

at a time.

3.

To check the differential,

observe the pressure on the

output gage for the point at

which the pressure drops to

zero. When the desired

differential is obtained,

retighten the locknut.

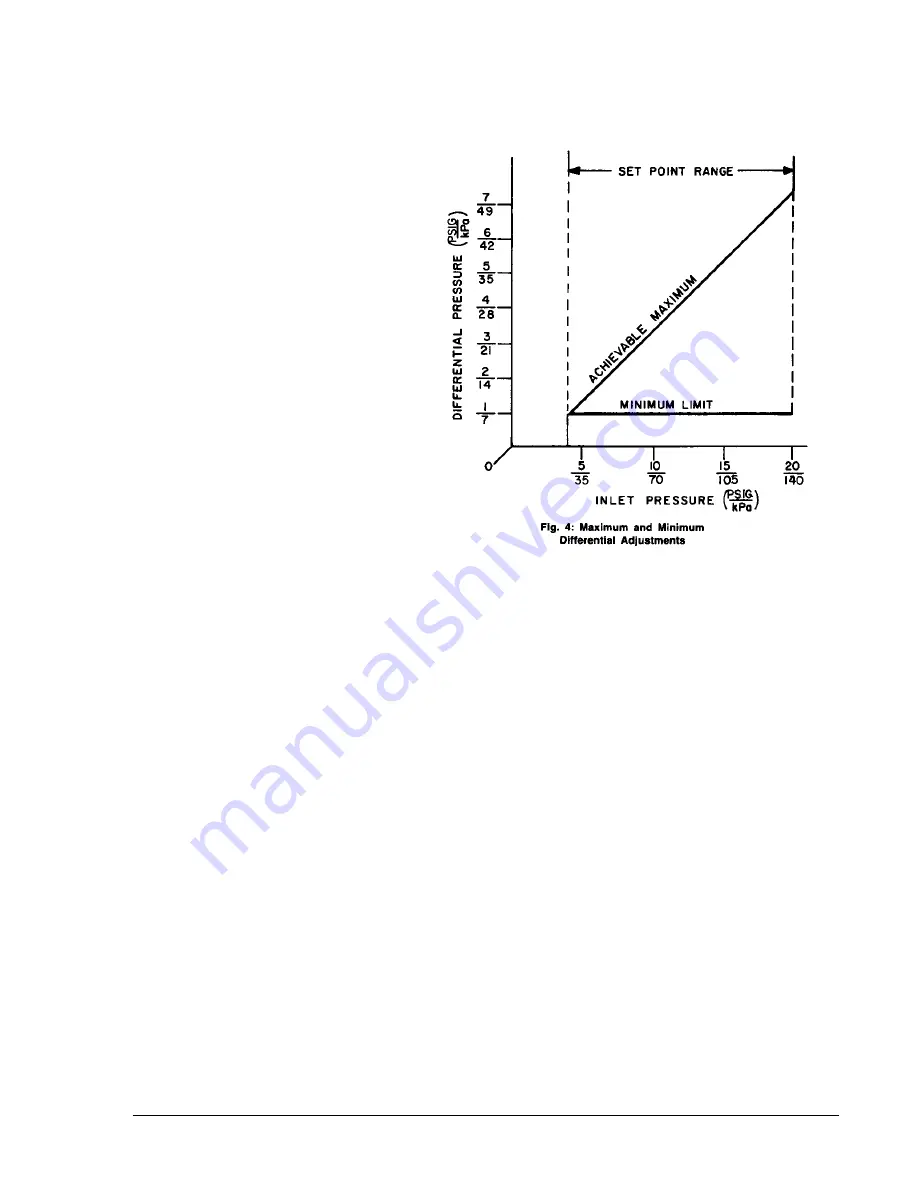

The maximum differential is

obtained by slowly turning the

screw clockwise into the body

until it stops, then backing it out

1/8 of a turn. Note: The screw

will stop because it contacts

the valve disc. Be careful not

to force the screw down onto

the disc. Refer to Fig. 4 for the

approximate maximum

differential pressures obtainable

for each respective set point.

Repair Information

If the C-9500 fails to operate

within its specifications, unit

replacement is required; field

repairs cannot be made.

Note: When checking or

replacing the C-9500, be sure

that the change in output

pressure will not upset the

system and cause damage (for

example allow a coil to freeze,

burn out a heater, collapse

duct work).