5156631-UIM-G-0417

2

Johnson Controls Unitary Products

INSPECTION

As soon as a unit is received, it should be inspected for possible dam-

age during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s delivery receipt. A separate request for

inspection by the carrier’s agent should be made in writing. See Local

Distributor for more information.

Requirements For Installing/Servicing R-410A Equipment

•

Gauge sets, hoses, refrigerant containers, and recovery system

must be designed to handle the POE type oils, and the higher

pressures of R-410A.

•

Manifold sets should be high side and low side with low side

retard.

•

All hoses must have a 700 psig service pressure rating.

•

Leak detectors should be designed to detect HFC refrigerant.

•

Recovery equipment (including refrigerant recovery containers)

must be specifically designed to handle R-410A.

•

Do not use an R-22 TXV.

LIMITATIONS

The unit should be installed in accordance with all National, State and

Local Safety Codes and the limitations listed below:

1.

Limitations for the indoor unit, coil, and appropriate accessories

must also be observed.

2.

The outdoor unit must not be installed with any duct work in the air

stream. The outdoor fan is the propeller type and is not designed

to operate against any additional external static pressure.

3.

The maximum and minimum conditions for operation must be

observed to ensure a system that will give maximum performance

with minimal service.

4.

The maximum allowable equivalent line length for this product is

80 feet.

Standard Lineset Applications

Maximum allowable lineset varies depending on the vertical separation

between the evaporator and condenser. See Table 2 for allowable line

set lengths and sizing.

Unit Reduced Capacity Conditions

SECTION III: UNIT INSTALLATION

LOCATION

Before starting the installation, select and check the suitability of the

location for both the indoor and outdoor unit. Observe all limitations and

clearance requirements.

The outdoor unit must have sufficient clearance for air entrance to the

condenser coil, air discharge, and service access. See Figures 1 & 2.

If the unit is to be installed on a hot sun exposed roof or a paved ground

area that is seasonally hot, the unit should be raised sufficiently above

the roof or ground to avoid taking the accumulated layer of hot air into

the outdoor unit (which can cause the unit to derate prematurely).

If the system is being installed during seasonally cold weather of 55°

F

or below, the preferred method is to weigh in the charge. For charging

or checking the system charge at 55

°

F or below, refer to the “Optional

Cold Weather Charging” procedures near the end of SECTION VI:

SYSTEM CHARGE. There is an “Optional Cold Weather Charging”

accessory kit to prevent the outdoor unit from taking in cold air below

55

°

F. The kit part number can be found in the list of accessory kits on

the UPGNET web site.

Provide adequate structural support for the unit.

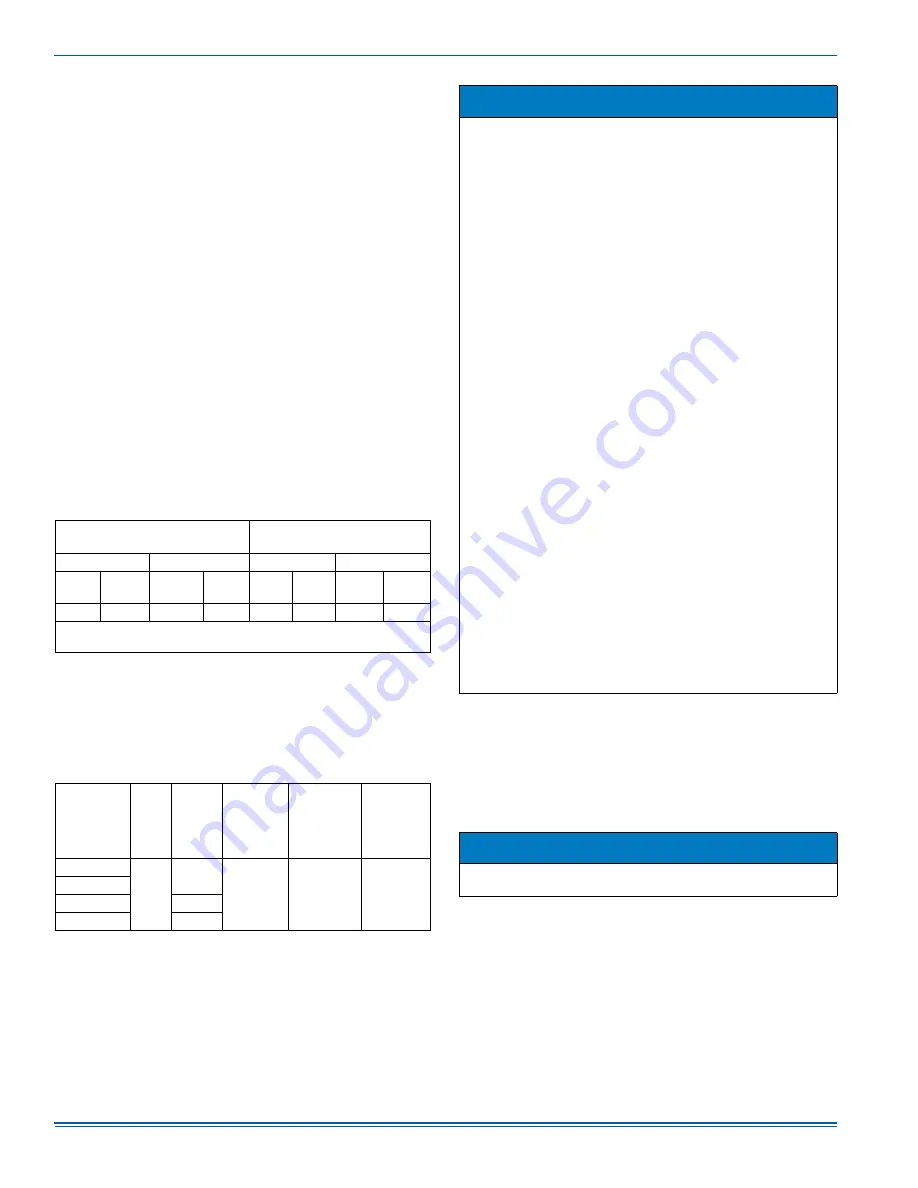

TABLE 1:

Minimum / Maximum Operating Limit Conditions

AIR TEMPERATURE AT

OUTDOOR COIL, ° F (° C)

AIR TEMPERATURE AT

INDOOR COIL, ° F (° C)

Min.

Max.

Min.

Max.

DB

Cool

DB

Heat

DB Cool

DB

Heat

WB

Cool

DB

Heat

WB

Cool

DB

Heat

35(2)* -20(-29) 125(52)* 75(24) 57(14) 50(10) 72(22)

80(27)

*

Reference the NOTICE under the “Unit Reduced Capacity Conditions”

section.

TABLE 2:

Allowable Vertical Linesets.

Model

Liquid

Line

Suction

Line

Max Line

Length -

Units on

Equal

Level

Max Suction

Line Riser -

If OD Unit is

Above ID

Unit

Max Liquid

Line Riser -

If OD Unit

is Below ID

Unit

24

3/8”

3/4”

80 feet

25 feet

25 feet

36

48

7/8”

60

1-1/8”

NOTICE

Intelligence Power Module (IPM) Temperature Protection:

If excessive (IPM) inverter temperatures are sensed, the compressor

speed / capacity is reduced every 60 seconds until an acceptable

condition is reached.

When the inverter temperature returns to an acceptable level, the

system returns to normal operation.

Over / Under Current Protection: If a low or high Current Condition

is sensed, the compressor speed / capacity is reduced every 30 sec-

onds until an acceptable current level is reached.

When the system reaches an acceptable current level, the compres-

sor and fan return to normal operating conditions.

Over / Under Voltage Protection: If a low or high supply Voltage

Condition is experienced (below 197 VAC or above 252 VAC), the

compressor speed / capacity is automatically reduced every 15 sec-

onds until an acceptable voltage level is sensed.

When an acceptable voltage level is sensed, the system automati-

cally returns to a normal state of operation.

High Outdoor Ambient Temperature Protection: During high out-

door ambient temperature conditions above 109°F (43°C), the com-

pressor speed reduces to protect the system. If the outdoor ambient

temperature goes above 125 °F (52°C), the system goes into a soft-

lockout condition halting operation for system protection. Consider

these limitations when installing any of the heat pumps included in

this document.

When the system reaches acceptable operating conditions, the sys-

tem returns to normal operation.

High Altitude Protection: If the unit is installed in Altitudes of 6,500

ft / 2,000 m above sea level or higher, the compressor and outdoor

fan reduce speeds to protect the system. It is not recommended

these units be installed at altitudes greater than 6,500 ft / 2,000 m

above sea level.

Low Ambient Protection:

Cooling mode: The unit automatically adjusts to maintain cooling

operation in outdoor ambient conditions down to 35° F (2° C). The

unit reduces capacity and or cycles off if asked to provide cooling

when the outdoor temperature is at or below these conditions.

Heating Mode: The unit provides compressor heat down to an out-

door ambient temperature of -20° F (-29° C). As the outdoor ambient

temperature reduces, available heat reduces for all air source heat

pumps. Make sure the balance point and auxiliary heat are appropri-

ately set and sized for the application of the heat pump.

NOTICE

For multiple unit installations, units must be spaced a minimum of 24”

(61 cm) apart (coil face to coil face).