SECTION 1 - SAFETY PRECAUTIONS

1-6

31215012

• Maintain distance from electrical lines, apparatus, or any ener

-

gized (exposed or insulated) parts according to the Minimum

Approach Distance (MAD) as shown in Table 1-1.

• Allow for machine movement and electrical line swaying.

• Maintain a clearance of at least 10 ft. (3m) between any part of

the machine and its occupants, their tools, and their equip

-

ment from any electrical line or apparatus carrying up to

50,000 volts. One foot additional clearance is required for

every additional 30,000 volts or less.

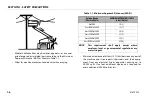

Table 1-1. Minimum Approach Distances (M.A.D.)

Voltage Range

(Phase to Phase)

MINIMUM APPROACH DISTANCE

in Feet (Meters)

0 to 50 KV

10 (3)

Over 50KV to 200 KV

15 (5)

Over 200 KV to 350 KV

20 (6)

Over 350 KV to 500 KV

25 (8)

Over 500 KV to 750 KV

35 (11)

Over 750 KV to 1000 KV

45 (14)

NOTE:

This requirement shall apply except where

employer, local or governmental regulations are

more stringent.

Summary of Contents for E450AJ

Page 6: ...FOREWORD d 31215012 REVISION LOG Original Issue A October 3 2019 Revision B September 28 2020...

Page 10: ...iv 31215012 TABLE OF CONTENTS...

Page 12: ...vi 31215012 LIST OF FIGURES...

Page 14: ...viii 31215012 LIST OF TABLES...

Page 56: ...SECTION 4 MACHINE OPERATION 4 6 31215012 Figure 4 3 Grade and Sideslope...

Page 80: ...SECTION 5 EMERGENCY PROCEDURES 5 4 31215012...

Page 108: ...SECTION 7 GENERAL SPECIFICATIONS OPERATOR MAINTENANCE 7 18 31215012...

Page 109: ......