SECTION 5 - CONTROL COMPONENTS

5-20

– JLG Lift –

3121222

5.8

BATTERY/BATTERY CHARGER

JLG mACHINES EQUIPPED WITH DELTA Q BATTERY CHARGERS ARE

DESIGNED FOR THE BEST PERFORMANCE WITH OEM FACTORY

APPROVED BATTERIES.

APPROVED JLG REPLACEMENT BATTERIES ARE AVAILABLE THROUGH

JLG'S AFTERMARKET PARTS DISTRIBUTION CENTERS OR JLG'S AFTER-

MARKET PROGRAMS. FOR ASSISTANCE WITH PROPER BATTERY

REPLACEMENT, PLEASE CONTACT YOUR LOCAL JLG SUPPORT OFFICE.

BATTERIES APPROVED BY JLG HAVE BEEN TESTED FOR COMPATIBILITY

WITH THE ALGORITHM PROGRAMMING OF THE DELTA Q BATTERY

CHARGER TO OPTIMIZE BATTERY LIFE AND MACHINE CYCLE TIMES.

THE USE OF NON APPROVED BATTERIES IN YOUR JLG EQUIPMENT MAY

RESULT IN PERFORMANCE ISSUES OR BATTERY CHARGER FAULT

CODES. JLG ASSUMES NO RESPONSIBILITY FOR SERVICE OR PERFOR-

MANCE ISSUES ARISING FROM THE USE OF NON APPROVED BATTER-

IES.

Before REMOVING ANY COMPONENT FROM THE ELECTRICAL SYSTEM,

DISCONNECT THE BATTERIES USING THE QUICK-DISCONNECT LOCATED

ON THE RIGHT SIDE BATTERIES.

Battery Maintenance and Safety Practices

ENSURE THAT BATTERY ACID DOES NOT COME INTO CONTACT WITH

SKIN OR CLOTHING. WEAR PROTECTIVE CLOTHING AND EYEWEAR

WHEN WORKING WITH BATTERIES. NEUTRALIZE ANY BATTERY ACID

SPILLS WITH BAKING SODA AND WATER.

BATTERY ACID RELEASES AN EXPLOSIVE GAS WHILE CHARGING,

ALLOW NO OPEN FLAMES, SPARKS OR LIGHTED TOBACCO PRODUCTS

IN THE AREA WHILE CHARGING BATTERIES. CHARGE BATTERIES ONLY

IN A WELL VENTILATED AREA.

ADD ONLY DISTILLED WATER TO BATTERIES. WHEN ADDING WATER

TO THE BATTERIES, A NON-METALLIC CONTAINER AND/OR FUNNEL

MUST BE USED.

DO NOT REPLACE ITEMS CRITICAL TO STABILITY, SUCH AS BATTERIES,

WITH ITEMS OF DIFFERENT WEIGHT OR SPECIFICATION. DO NOT MOD-

IFY UNIT IN ANY WAY TO AFFECT STABILITY.

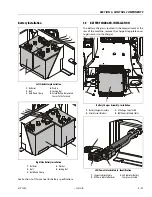

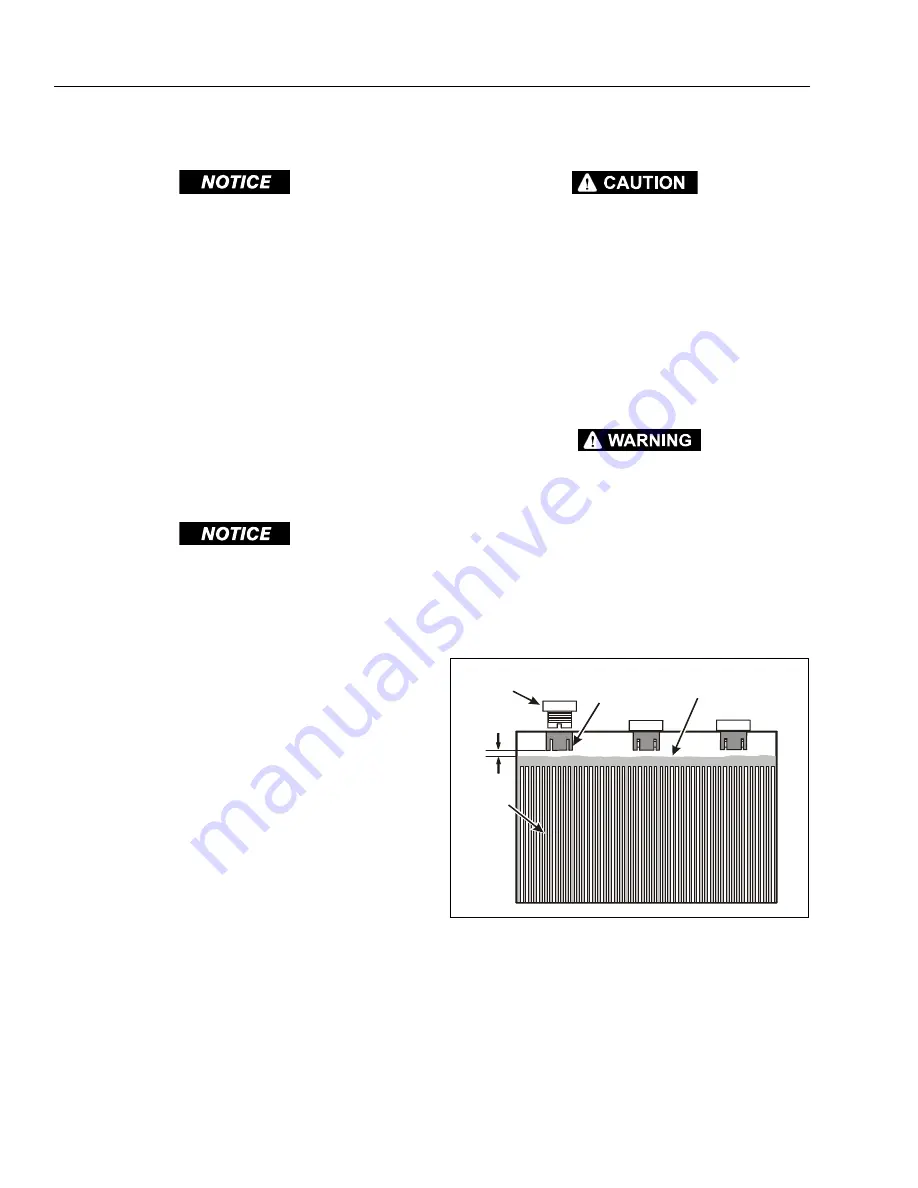

Check the electrolyte level of the batteries often, adding

only distilled water when required. When fully charged,

battery fluid level should be 1/8" below vent tubes.

(See

.

•

DO NOT fill to bottom of vent tubes.

•

DO NOT allow fluid level to go below the top of the

plates when charging or operating.

Figure 5-8. Battery Fluid Level.

1/8 "

BATTERY

FILLER CAP

FLUID LEVEL OF FULLY

CHARGED BATTERY

VENT TUBE

PLATES

Summary of Contents for 1230ES

Page 1: ...AS NZS Service and Maintenance Manual Model s 1230ES P N 3121222 June 22 2017 ...

Page 2: ...NOTES ...

Page 24: ...SECTION 1 MACHINE SPECIFICATIONS 1 12 JLG Lift 3121222 NOTES ...

Page 32: ...SECTION 2 GENERAL SERVICE INFORMATION 2 8 JLG Lift 3121222 NOTES ...

Page 78: ...SECTION 4 BASE COMPONENTS 4 40 JLG Lift 3121222 NOTES ...

Page 104: ...SECTION 5 CONTROL COMPONENTS 5 26 JLG Lift 3121222 NOTES ...

Page 158: ...SECTION 8 DIAGNOSTIC TROUBLE CODES 8 22 JLG Lift 3121222 NOTES ...

Page 198: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 40 JLG Lift 3121222 ...

Page 199: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 3121222 JLG Lift 9 41 ...

Page 200: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 42 JLG Lift 3121222 ...

Page 202: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 44 JLG Lift 3121222 NOTES ...