7

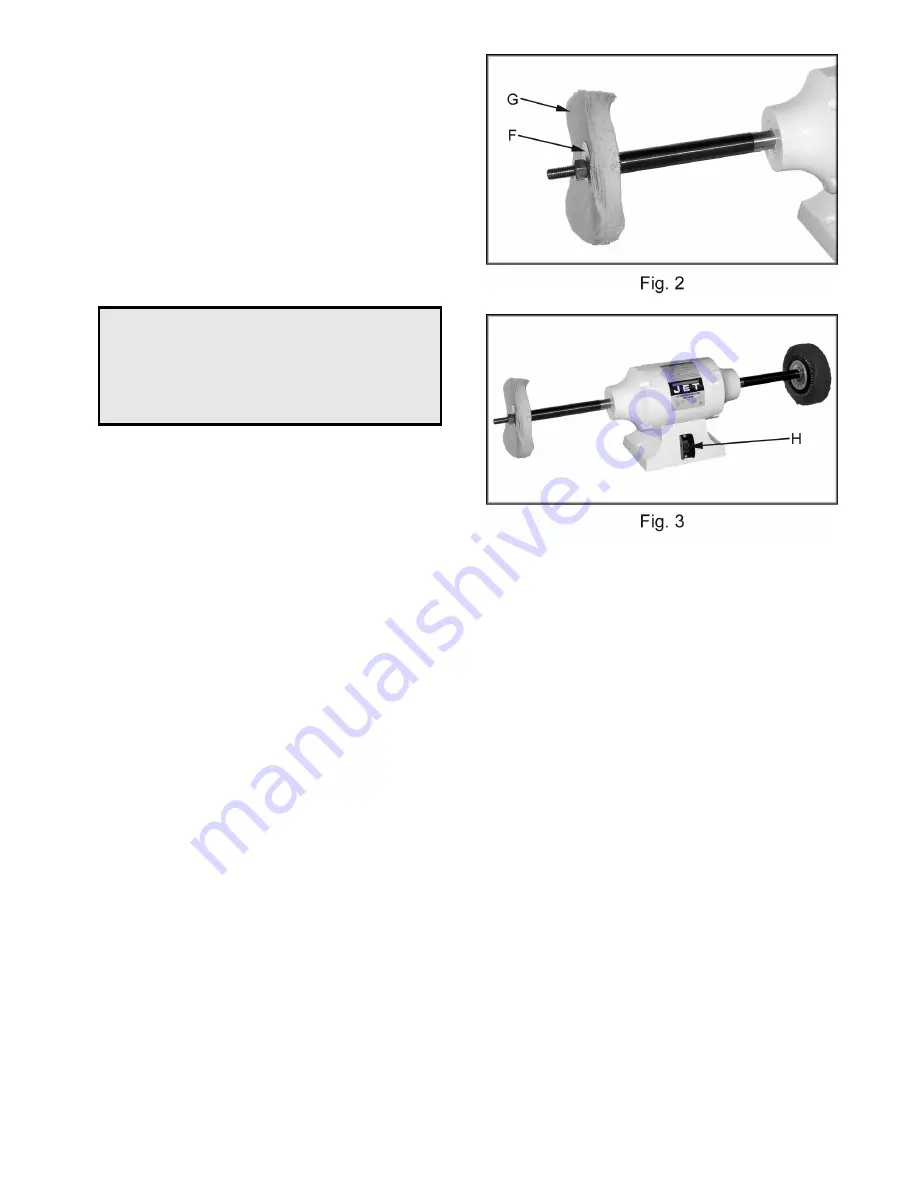

5. Use the flange washers (F, Fig. 2) on either

side of soft accessories such as, buffing

wheels (G, Fig. 2). Note: If the accessory

has a 5/8" ID mount on the threaded section

of the shaft along with the 5/8” ID flanges. If

the accessory has a 1” ID mount on the

main portion of the shaft using the 1” ID

flanges.

6. Turn the buffer / sander on and off by using

toggle switch (H, Fig. 3).

Buffing & Polishing

WARNING

Never sand or buff with the workpiece on top

of the wheel. The workpiece may be catch

the wheel and be thrown at the operator.

Always process the workpiece near the

bottom of the wheel!

1. Select the appropriate stick of polishing

compound for your application and apply to

the rotating face of the wheel.

2. Start the buffer and with both hands firmly

grasp the item to be polished. Lightly and

evenly move the workpiece back and forth

on the buffing wheel.

Drum Sanding

1. Slide sanding sleeve onto the drum. Ensure

that the arrows on the inside of the sleeve

point in the direction of the drum rotation.

2. Inflate the drum using a hand pump. Some

sanding applications may require more, or

less air in the drum. The maximum air

pressure is 10 psi. Do not over inflate!

3. Flip the switch up to turn the machine on

and firmly grasp the workpiece to be

sanded.

4. With light and even pressure against the

direction of rotation, move the workpiece

back and forth on the sanding drum. Sand

in the direction of the wood grain.

Sanding and Buffing Accessories

Jet offers a wide variety of sanding, buffing and

polishing accessories for use with this machine.

Visit www.wmhtoolgroup.com and go to JET

Woodworking Accessories to view the options.

Then visit your local JET Distributor to make a

purchase.