4

www.jetgroupbrands.com

Operating Instructions

1. Check Coolant: Low coolant level causes

foaming and high blade temperatures. Dirty or

weak coolant can clog pump, causes crooked

cuts, low cutting rate and permanent blade

failure. Dirty coolant causes the growth of

bacteria with ensuing skin irritation. Coolant is

water soluble.

2. Keep vise slides clean and oiled.

3. Clean chips from blade wheels and the areas

around wheels. Keep chip brush in good repair.

4. Saw Guide: Keep saw guides properly adjusted.

Loose guides will affect cutting accuracy.

5. Check saw blade for sharpness.

6. Blade Speed: Is blade speed set correctly for

workpiece material and shape?

7. Check Blade Tension: Particularly after initial

cuts with a new blade.

Blade Selection

A. Never use a blade so coarse that less than 3

teeth are engaged in the workpiece at any time.

(Too few teeth will cause teeth to strip out.)

B. Never use a blade finer than required to obtain a

satisfactory surface finish or satisfactory flatness.

(Too many teeth engaged in the work piece will

reduce sawing rate; cause premature blade wear;

produce “dished” cuts or cuts which are neither

square nor parallel.)

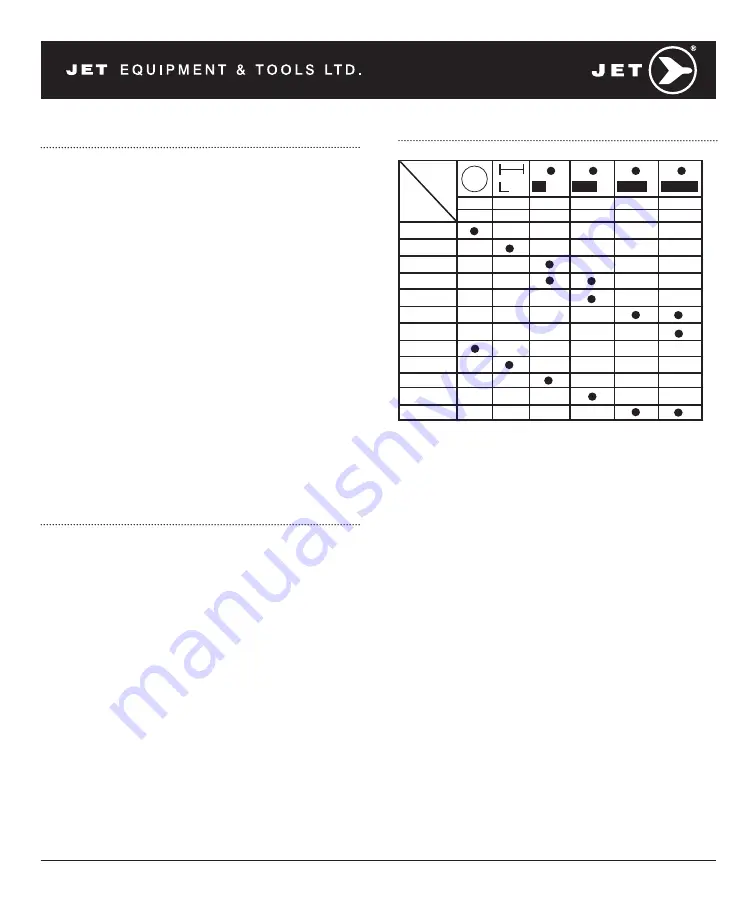

C. The chart which follows is intended as a general

guide to good sawing practices. Consult

your blade supplier or qualified technician for

complete information for operational details of

saw blades and their use.

The Selection of Saw Blades

Remarks:

HSS-High Speed Steel Sawblade

HCS-High Carbon Steel Sawblade

NOTE:

1. When standard wall pipe, tubes, channel iron

and angle I beams are cut, a 10 pitch saw blade

of wave-set type or sawblade of (HSS) 6/10T is

frequently used to good advantage.

2. Tubes or materials with wall thickness or web

thickness of 1/2" or more can usually use an 8 or

6 pitch sawblade of (HSS) 4/6T satisfactorily.

3. When rectangular solid bar stock is to be sawed,

the work should be loaded so that the cut is

made across the thinnest cross section. The

pitch (or number of teeth per inch of blade)

selected must provide engagement of at least 3

teeth in the workpiece. Should application of this

rule not be possible because the thinnest cross

section is too thin, the piece must be loaded so

that the cut is made across the wider dimension

and a coarser blade selected from the listing of

recommendations for round and square

solid bars.

Cutting

Material

<3mm >5mm >50mm >100mm >150mm >200mm

Sawblade

<0.12"

>0.2"

>2" >4" >6" >8"

(HSS)

14T

(HSS)

6/10T

(HSS)

5/8T

(HSS)

4/6T

(HSS)

3/4T

(HSS)

2/3T

(HSS)

1/2T

(HCS)

10T

(HCS)

8T

(HCS)

6T

(HCS)

4T

(HCS)

2T

Summary of Contents for JHBS916

Page 5: ...5 www jetgroupbrands com ...

Page 15: ...15 www jetgroupbrands com ...

Page 16: ...16 www jetgroupbrands com ...