6

JCT-5670 Pneumatic Drill

Setup and Assembly

Any missing parts or damage should be reported

immediately to your JET

®

distributor. Do not use a

damaged tool. Read this instruction manual

thoroughly for operation, maintenance and safety

instructions.

Box contents:

1 Drill

1 Side

handle

1 Screw

1 Chuck

key

1/2in.

1

Operation and parts manual

1 Warranty

card

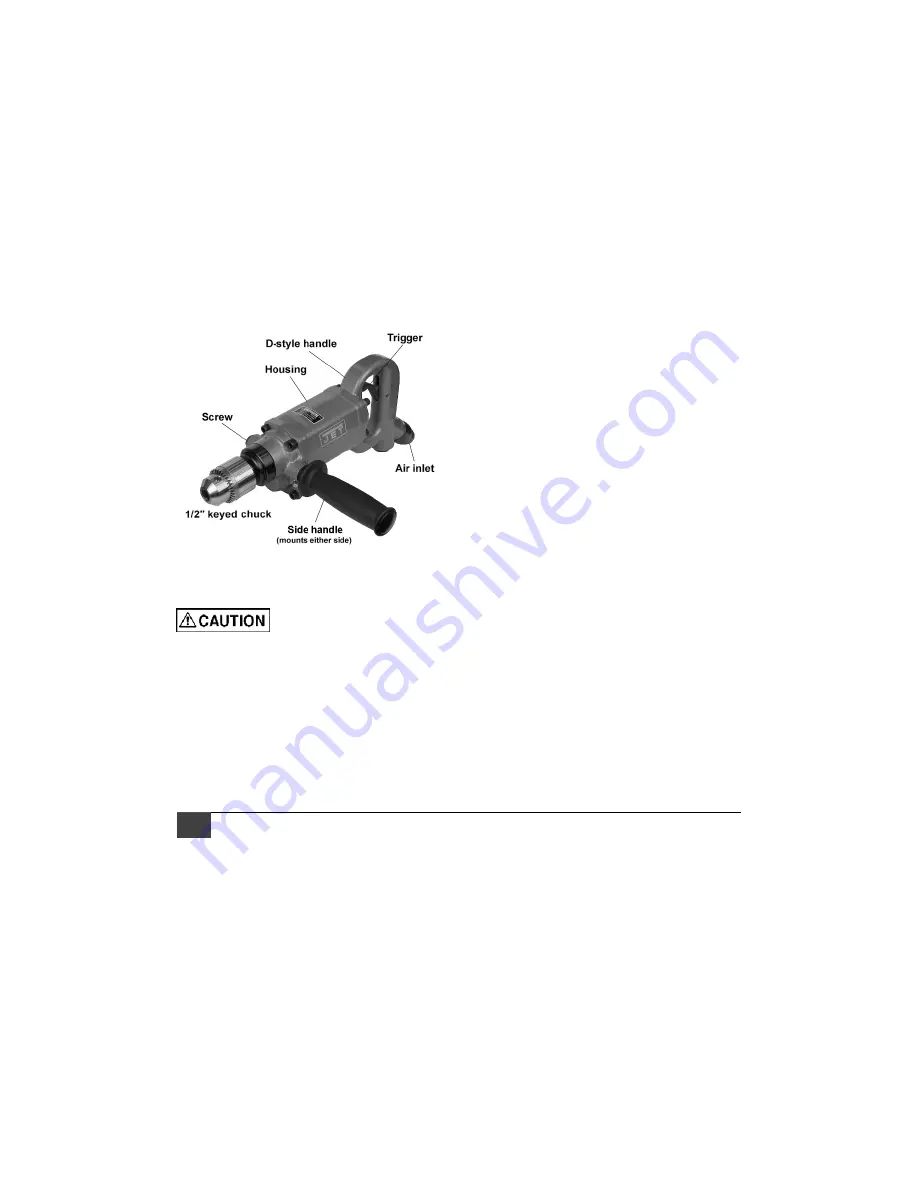

Install side handle on either side of drill for left or

right hand operation. Install screw on opposite

side to protect the threads. See Figure 1.

Figure 1

Operation

The drill must be properly

lubricated before operation. See “Lubrication”

section.

1.

Remove protective cap from air inlet (Figure

1). If an in-line oiler is not being used, add 4

or 5 drops of air tool oil (not included) into the

air inlet.

2. Blow out air line to remove any dirt or

moisture, then connect air supply hose to

tool. Set air pressure to 90 psi.

IMPORTANT:

Connecting a quick-change

coupling directly to the tool is not

recommended, as vibration may cause the

connection to fail. Instead, add a leader hose

and install any quick-change couplings

farther down the line.

3.

Rotate chuck counterclockwise by hand to

open chuck jaws.

4. Insert bit (not provided) into chuck, and

center it between the jaws. Tighten chuck by

hand while aligning bit.

Note: Insert only the shank of a twist drill bit;

its flutes should remain free of the chuck

jaws.

5.

Insert chuck key into one of the holes on the

chuck, so it meshes with teeth on drill chuck.

Rotate key clockwise to fully tighten chuck.

6.

Place bit against work item and gently press

trigger. Speed is variable, determined by

pressure against trigger. Begin at slow

speed and gradually increase as you drill.

7.

Release trigger to stop drill.

Important:

DO NOT raise air pressure

above maximum rating for this drill. If tool is

not accomplishing task at maximum air

pressure and flow, use a larger tool or

different means to achieve task.

User-maintenance

Lubrication

The drill should be lubricated

daily

(or before

each use) with air tool oil through the air inlet.

During continual operation, it should be re-oiled

every 1 to 2 hours. This can be done with an in-

line oiler, or manually. If done manually, proceed

as follows:

1.

Disconnect air hose from tool.

2.

Place 4 or 5 drops of air tool oil into air inlet.

NOTE: Air tool oil not provided; it is available

at most major hardware and tool stores. SAE

#10 oil or sewing machine oil may be used

as a substitute. Do not use detergent oil.

3. Re-connect air. Run drill at low throttle

without load for a few seconds to distribute

the oil throughout tool.