14

Adjusting Blade Tracking

WARNING

Blade tracking adjustment requires running

the saw with the back cover open! This

adjustment must be completed by qualified

persons only!

Failure to comply may cause serious injury!

Blade tracking has been set at the factory and

should not need immediate adjustment. If blade

tracking should ever require adjustment:

1. Confirm that blade tension is set properly.

To adjust, see section titled " Adjusting

Blade Tension".

2. Make sure the saw is in its slowest speed,

see “Changing Blade Speeds”.

3. Move saw arm to the vertical position and

lock in place with the lock lever.

4. Confirm that blade tension is set properly.

To adjust, see section titled " Adjusting

Blade Tension".

5. Open blade cover by removing the knob

found on the top side of the bow.

6. Run saw and observe blade. Blade should

run next to but not tightly against wheel

flange.

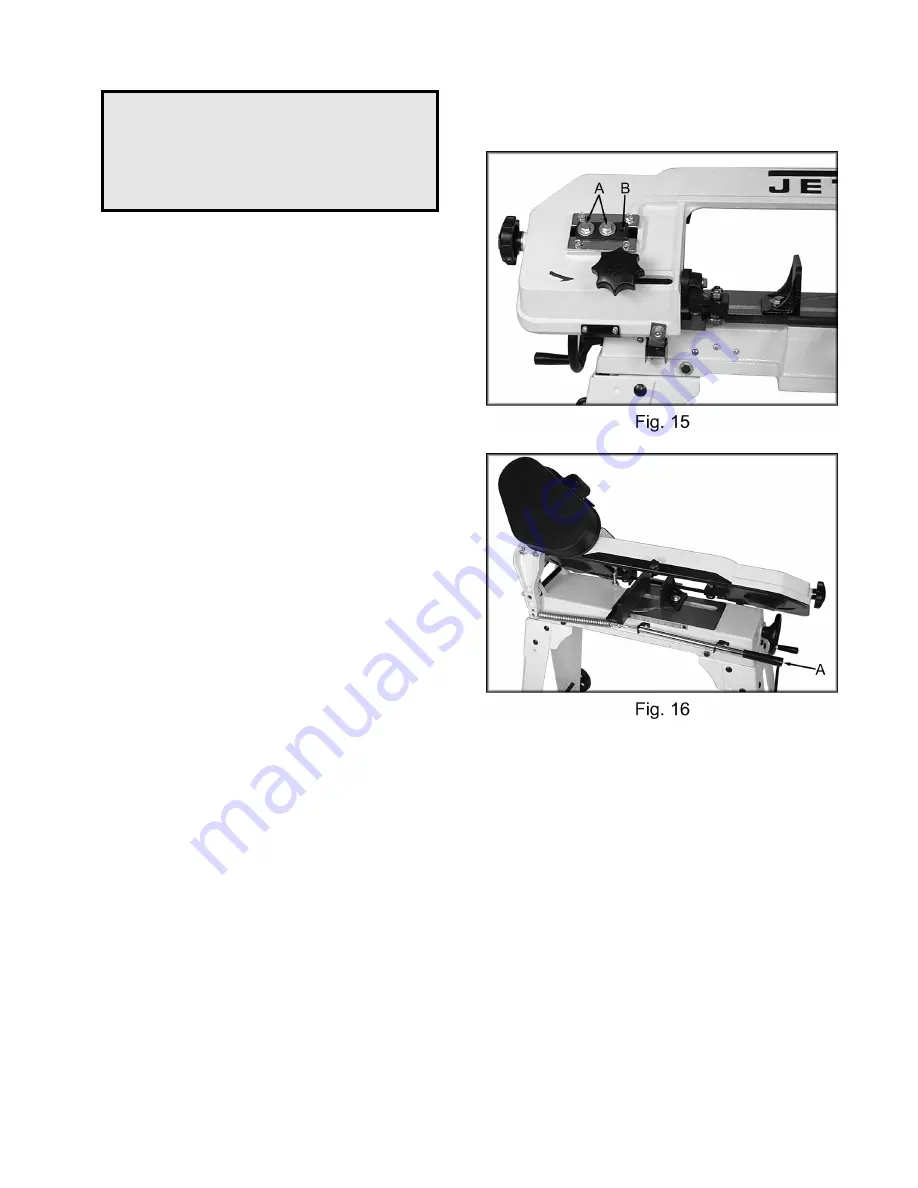

7. Loosen bolts (A, Fig. 15).

8. Turn set screw (B, Fig. 15) while observing

blade tracking on wheel. Turn set screw

clockwise to track closer to wheel flange.

Turn set screw counter-clockwise to track

away from the wheel flange.

Hint:

start

with ¼ turns on the set screw. The tracking

is sensitive.

9. Once tracking is set, tighten bolts (A, Fig.

15).

Adjusting Feed Pressure

1. Turn handle (A, Fig. 16) clockwise to

decrease cutting pressure and counter-

clockwise to increase cutting pressure.

A good indication of proper feed pressure is the

color and shape of the cutting chips. If the chips

are thin or powdered, increase the feed pressure.

If the chips are burned and heavy, decrease the

feed pressure. If they are still burned and heavy,

reduce the blade speed. Optimum feed

pressure has been set when the chips are curled,

silvery, and warm.

Summary of Contents for HVBS-56M

Page 17: ...17 Breakdown for Bow Assembly ...

Page 18: ...18 Breakdown for Base Assembly ...

Page 22: ...22 Wiring Diagram ...

Page 23: ...23 Notes ...