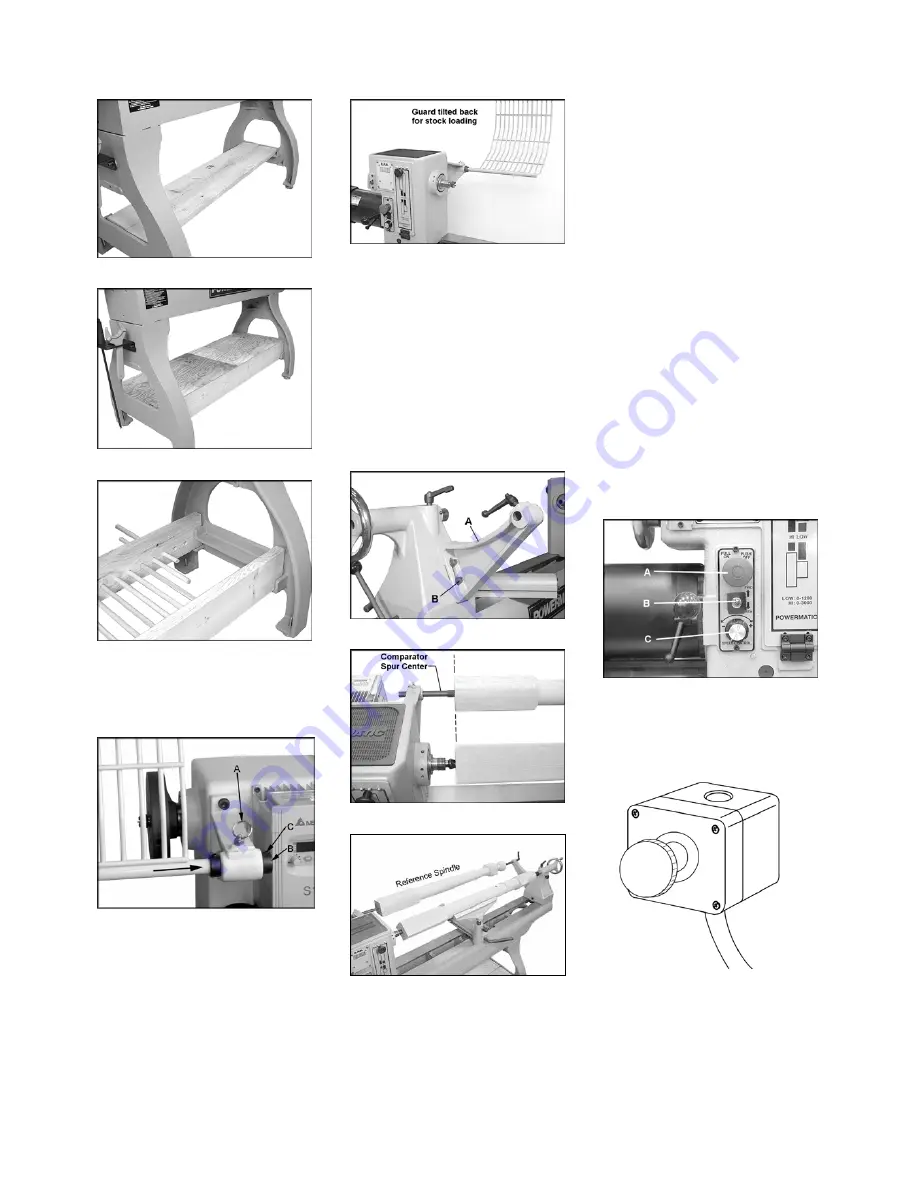

Fig 5

Fig 6

Fig 7

Guard assembly:

Attach guard to the bracket by

inserting the rod and lifting up on the

plunger (A, Fig 8).

Fig 8

There are two detents that will hold the

guard in place.

One is for turning and the other is for

when you need the guard up and out

of the way.

Tighten the bushings (B) against the

bracket with two set screws (C).

Fig 9

Optical comparator assembly:

Mount the comparator rear bracket (A,

Fig 10) to the back of the tailstock with

two socket head cap screws, lock

washers and washers (B).

The bracket has a slot so it can be

aligned with the bracket on the

headstock.

The comparator allows to hold a

sample workpiece for optical reference

and comparative measurement taking.

( see Fig 11-12).

Fig 10

Fig 11

Fig 12

5.3 Mains connection

Mains connection and any extension

cords used must comply with

applicable regulations.

The mains voltage must comply with

the information on the machine licence

plate.

The mains connection must have a

16 A surge-proof fuse.

Only use power cords marked H07RN-

F

Connections and repairs to the

electrical equipment may only be

carried out by qualified electricians.

5.4 Dust collection

Use a suitable dust collection and

filtration system to avoid a high dust

concentrations in the air.

5.5 Starting operation

You can start the machine by pulling

the red ON/OFF button (A, Fig 13).

Fig 13

The machine will stop when you push

the red ON/OFF button (A, Fig 13) or

the remote control ON/OFF button (Fig

14).

Fig 14

Turn the knob (C) to the desired RPM.

There are 2 speed ranges offering

“speed” (0-3200 rpm) and

“torque” (0-1200 rpm).