AAA-055-00138

Rev. 1/14/15

Jaylor Owner Manual

- 56 -

Mini Mixer Models

29.0

HYDRAULIC SYSTEM MAINTENANCE

Refer to section ‘

’ for the recommended oil to use in the hydraulic

system of your A50 or A100 model. Use section ‘

36.0 Maintenance and Service Records

’ to

keep a record of all scheduled servicing.

All A50 and A100 models (except the A50 skid steer model) are equipped with a hydraulic system

with reservoir.

Check the reservoir oil level daily

. Check for oil leaks every 8 hours or

whenever the oil level drops rapidly. Inspect the oil condition for cloudiness and/or impurities.

To maintain the hydraulic system, use the following procedures:

1. Clear the area of bystanders, especially small children.

2. Park the mixer on a flat, level surface, put controls in neutral, apply parking brake if

equipped (if not, block wheels), stop engine, remove ignition key, and wait for all moving

parts to stop. Also, be sure to let engine and hydraulic system cool to a safe temperature

before servicing, adjusting or repairing any of these components. Disconnect the spark

plug lead and ground it to ensure the engine does not start unexpectedly.

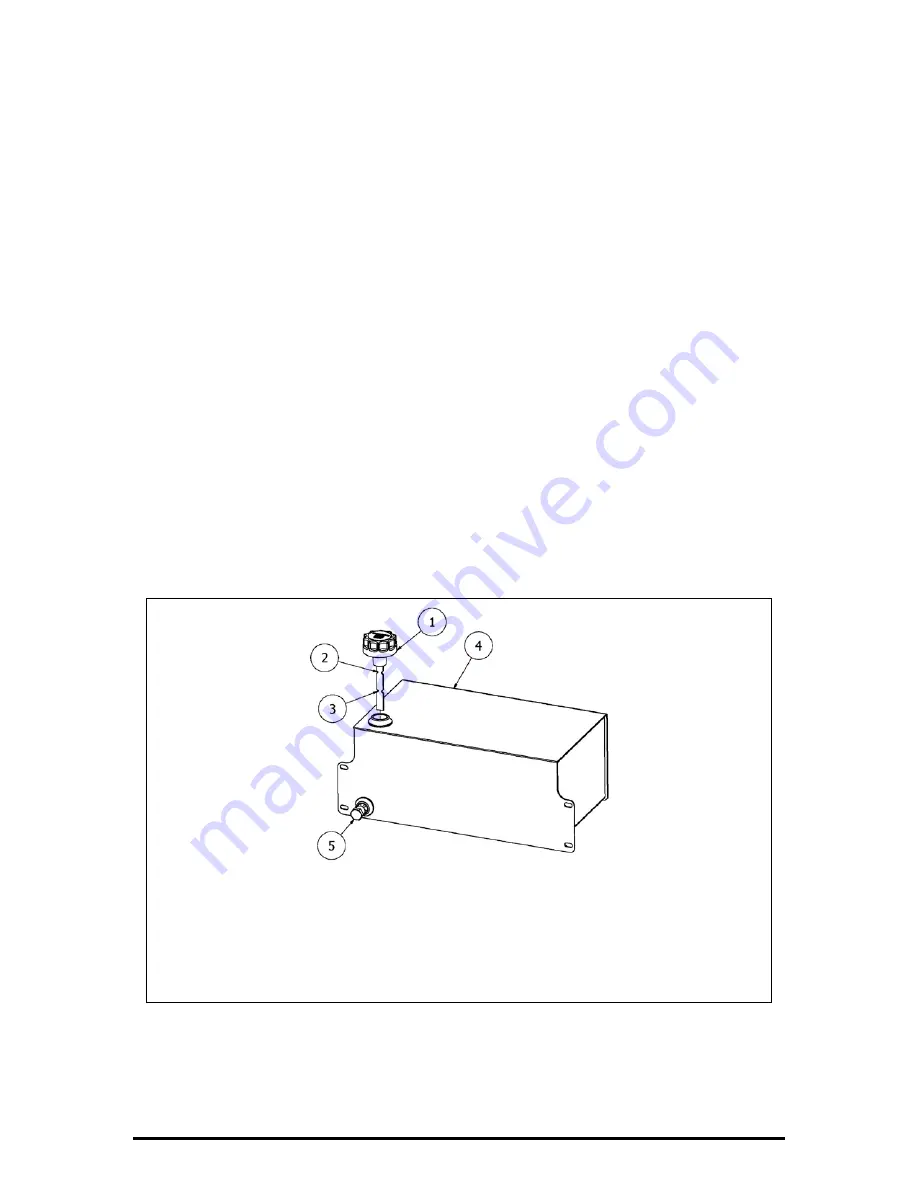

29.1 Checking Level in Hydraulic Oil Reservoir (A50 Models except Skid Steer)

Each hydraulic system is equipped with an oil reservoir and breather/filter cap mounted on the

back end of the mixer under frame. The oil level must be

checked daily

when the oil is cool and

machine is level. Add oil through the vented cap as required to maintain the oil level between the

grooves as identified on the reservoir dipstick (see

Figure 44 - A50 Hydraulic System Oil Reservoir

1. Breather Cap and Dipstick

2. Maximum Level Groove

- Indicates the maximum hydraulic oil level in the reservoir.

3. Minimum Level Groove

- Indicates the minimum hydraulic oil level in the reservoir.

4. Hydraulic Oil Reservoir

5. Hydraulic Oil Reservoir Drain Plug