9

whether the gas circuit of the welding torch is blocked.

4.Unsealed gas circuit or gas with low purity may affect the quality of welding.

5. Strong airflow may degrade the welding quality.

B. Arc is hard to start and easy to break:

1. Make sure the tungsten electrode is of good quality. Tungsten electrode of poor quality may lead low ability

of discharge.

2. Tungsten electrode which is not sharp may make arc hard to start and unsteady.

C. Output currant is lower than rated value:

Deviant Supplied voltage will lead the mismatch of the output current and setting value. When supplied voltage

is lower than the rated value, the maximum output current may be lower than rated value.

D. Unsteady current during the operating:

It may be related with factors below:

1. Voltage change of electric network;

2. Severely interference of electric network or other electrical equipment.

E .Serious burned tungsten electrode:

The tungsten electrode has a long electron emission time because the duty ratio is bigger and the electrode is over

heated.

F. Oxidized film on aluminum workpiece surface can not be exposed when welding:

1. Wrong position selection.

2. Insufficient duty ratio adjustment.

3. Double-times invert MOSFET is damaged.

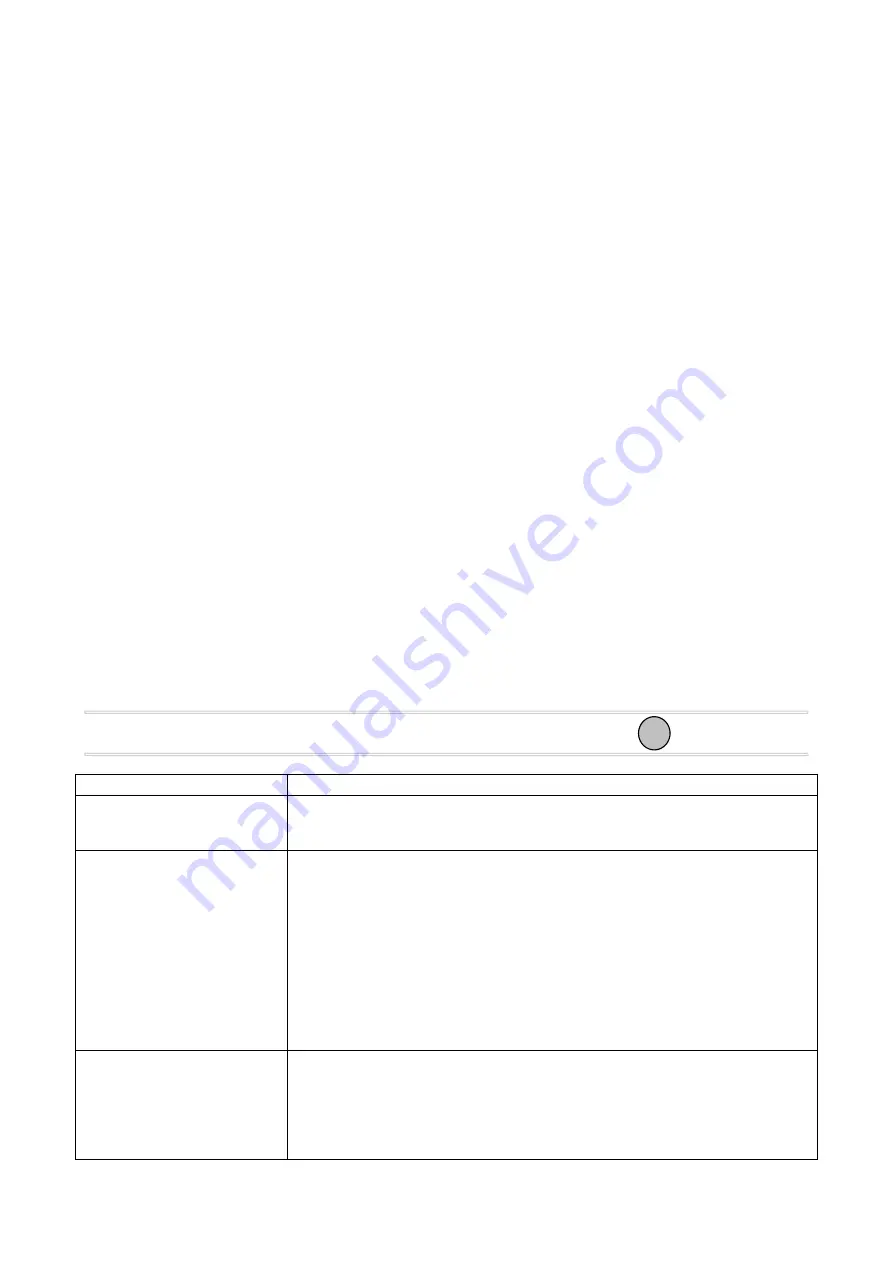

Troubleshooting

AC.DC TIG-200

Failure phenomenon

Measures

Power indicator does not light, and fan

does not rotate, but no welding output.

1. The power switch is damaged .

2. Check the power network connected with input cable and assure it is available.

3. Check input cable and find out any short circuit.

Power indicator lights, but fan does

not rotate or stops after several

rotations, and no welding output.

1. The welding machine may wrongly connected with 380V power supply, so over-voltage

protection circuit is active. Connect the machine to 220V power supply and restart.

2. Unstable 220V power supply(thin and long input cable) or the input cable drops on power

network and over-voltage protection circuit is active. Increase the diameter of input cable or

fasten the connecting point of input cable. Turn off the welding machine and restart it after 2-3

minutes.

3. Continuously turn on and off the power switch in a very short time and over-voltage protection

circuit is active. Turn off the welding machine and restart it after 2-3 minutes.

4. The cable between switch and power board is loose, pls re-tight it.

5. 24V relay on the main circuit of power board is inactive or damaged. Check the 24V power

supply and relay.

Fan rotates and abnormal indicator

does not light, and no “susurrus”

sound generated by high frequency

discharge, and no arc starting for

“rubbing arc welding”

1. Check the voltage between the VH-07 inserter on MOS board and power board with multimeter

and the value should be around DC308V.

2. There is a green indicator used on auxiliary power supply of MOS board, if it does not light,

that mean the auxiliary power supply is inactive. Pls find out where the failure locates or contact

with dealer.

3. Check connecting wires in the machine and find out any bad connection.

i