56

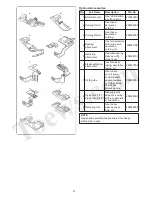

Troubleshooting

Condition

Cause

Reference

The machine

does not operate.

1. The machine is not been plugged in properly.

2. The power switch is turned off.

3. The safety device is activated.

Refer to page 7.

Turn the power switch ON.

Refer to page 4.

The fabric is

not being fed

smoothly.

1. The presser foot is raised.

2. The foot pressure is too low.

3. The feed dog is packed with lint.

Lower the presser foot.

Refer to page 10

Refer to page 52.

The needle

breaks.

1. The wrong needle is used or the needle is incorrectly inserted.

2. The needle is bent or worn.

3. The fabric is forcibly pulled.

Refer to page 10.

Refer to page 10.

Pull the fabric lightly.

The thread

breaks.

1. The machine is not correctly threaded or the thread is tangled.

2. The thread tension is too tight.

3. The wrong needle is used or the needle is incorrectly inserted.

4. The needle is bent or blunt.

5. A poor quality thread is used.

Refer to pages 19-32.

Refer to pages 37-41 and 45.

Refer to page 10.

Refer to page 10.

Refer to page 15.

Skipped stitches

1. The wrong needle is used or the needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The machine is not correctly threaded or the thread is tangled.

Refer to page 10.

Refer to page 10.

Refer to pages 19-32.

The seam is not

sewn neatly.

1. The thread is not correctly inserted between the tension disks.

2. The thread tension is too strong or too loose.

3. The machine is not correctly threaded or the thread is tangled.

4. The chaining finger is not set correctly.

5. The needle and/or the thread are not suitable for the fabric being

sewn.

Refer to pages 19, 22, 28 and

31

Refer to pages 37-41 and 45.

Refer to pages 19-32.

Refer to page 13.

Refer to pages 33, 42, 46-49.

Seam puckering

1. The thread tension is too tight.

2. The machine is not correctly threaded or the thread is tangled.

3. The stitch length dial and/or the differential feed dial is not

correctly adjusted.

4. The chaining finger is not set correctly.

Refer to pages 37-41 and 45.

Refer to pages 19-32.

Refer to pages 33, 42, 46-49.

Refer to page 13.

The fabric curls.

1. The upper looper thread tension or the lower looper thread

tension is too tight.

2. The chaining finger is not set correctly.

Refer to pages 38-41 and 45.

Refer to page 13.

The fabric is not

cut neatly.

1. The upper knife is deactivated.

2. The upper knife is dull.

Refer to page 12.

Refer to page 54.

The cutting width

is too narrow or

too wide for the

seam width.

1. The cutting width is not adjusted correctly.

Refer to page 12.

The looper

threader does not

work.

1. The looper threader switch lever is not set to the

“THREADING”

position.

2. The looper selection lever is not set correctly.

3. The thread is not inserted into the looper threader hole 2 cm or

more.

4. The thread is not drawn long enough before it is inserted into the

looper threader hole.

5. The thread is tangled in front of the looper threader hole.

6. The thread is wet.

7. The thread is frayed.

8. Lint is accumulated in the looper threader pipe.

Refer to pages 20, 23.

Refer to pages 20, 23.

Refer to pages 20, 23.

Refer to pages 20, 23.

Refer to pages 20, 23.

Trim the wet thread end.

Trim the thread end.

Refer to page 53.

The needle

threader does not

work.

1. The

“o” mark on the belt cover is not aligned with the “-” mark on

the handwheel.

2. The needle threader switch lever is not set correctly.

3. The needle threader is not used correctly.

Refer to page 30.

Refer to page 30.

Refer to page 30.