10

MECHANICAL ADJUSTMENT

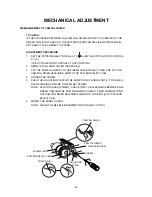

NEEDLE SWING

TO CHECK:

WHEN SEWING THE ZIGZAG PATTERN (WITH MAXIMUM ZIGZAG WIDTH), IF THE

NEEDLE BAR STARTS MOVING SIDEWAYS WHILE THE NEEDLE IS IN THE FABRIC,

ADJUST THE NEEDLE SWING ACCORDING TO THE FOLLOWING PROCEDURE.

ADJUSTMENT PROCEDURE:

1.

SET THE PATTERN SELECTOR DIAL WITH MAXIMUM ZIGZAG WIDTH, AND REMOVE

THE TOP COVER (SEE PAGE 4).

2.

LOOSEN THE TWO SETSCREWS.

3.

ADJUST THE NEEDLE SWING BY TURNING THE HANDWHEEL, WHILE HOLDING THE

WORM SO AS NOT TO ROTATE IT, UNTIL THE NEEDLE SWING STARTS AT 2–3 MM

ABOVE THE NEEDLE PLATE AFTER THE NEEDLE HAS COME OUT OF THE RIGHT

SIDE OF THE NEEDLE PLATE HOLE.

4.

TIGHTEN TWO SETSCREWS.

5.

ATTACH THE TOP COVER.

NOTE: AFTER ADJUSTING THE NEEDLE SWING, CHECK THAT THE UPPER SHAFT

WORM AND GEAR ROTATE SMOOTHLY WITHOUT ANY BACKLASH

BETWEEN THEM.

2–3MM

UPPER SHAFT WORM

GEAR

SETSCREW

(2 PCS.)

Summary of Contents for 415

Page 1: ...SERVICING MANUAL 419S 423S 415...

Page 26: ...24 WIRING FOR 110 120V FROM LAMP SOCKET FROM MOTOR FROM MOTOR FROM LAMP SOCKET FOR 220 240V...

Page 27: ...PARTS LIST MODEL 423S 419S...

Page 34: ...PARTS LIST 1 2 3 4 5 8 8 7 6 6 9 10 11 12 13 14 15 16 17 18 19 20 21 22 7...

Page 38: ...PARTS LIST 1 7 8 9 11 4 12 13 14 10 2 3 4 4 5 6 4 4 4 15 16 17 10 18 19 20 21 22 11...

Page 42: ...PARTS LIST 1 2 3 4 5 6 7 8 9 10 15...