21

Correct Condition

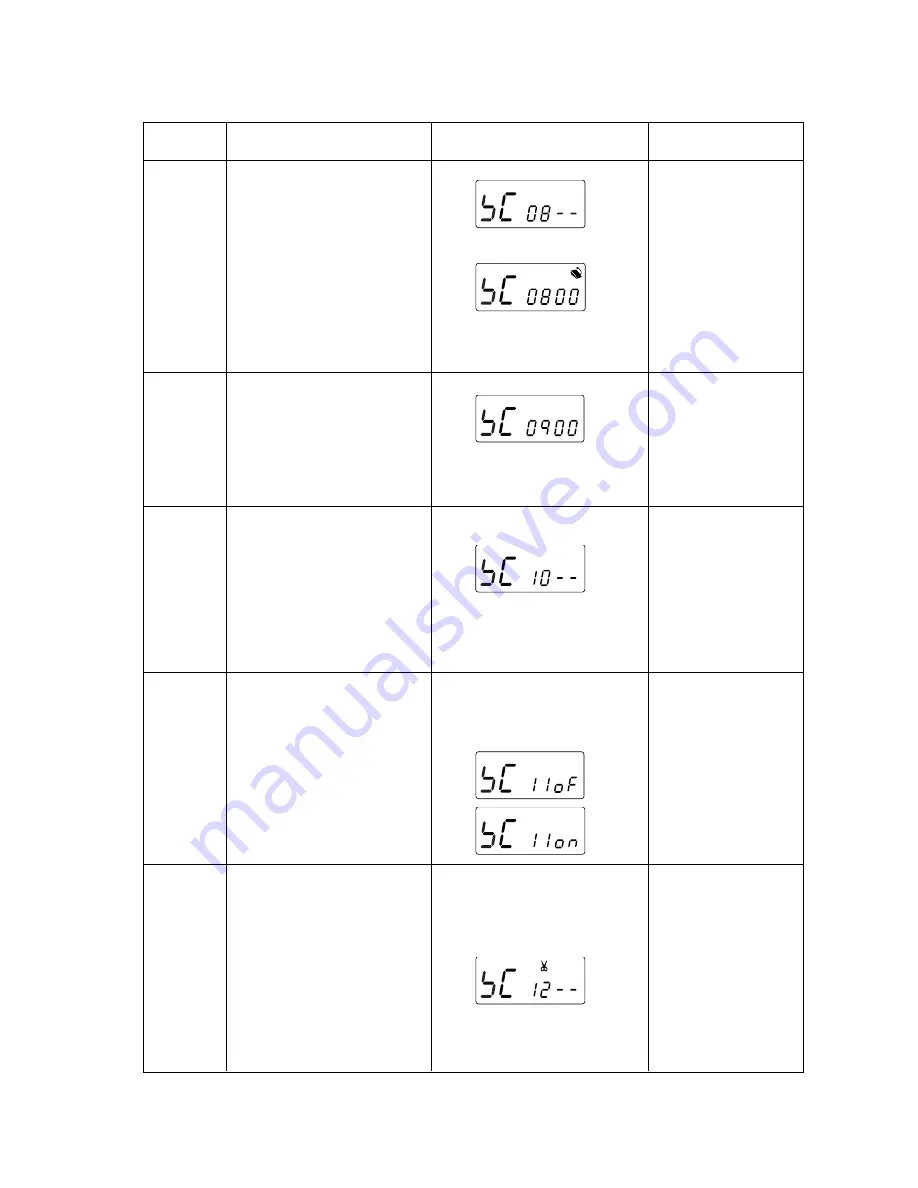

LCD displays “SC 08”.

Step and

items to check

08)

Foot control

Procedure

Attach the foot control to the sewing

machine.

Depress the foot control as far as it

goes, then release it.

If the result is correct condition, press

the start/stop button to proceed the

next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

Defective Condition

The foot control symbol does

not appear.

Buzzer does not sound.

–REMEDY–

Replace the foot control.

Replace the machine socket.

Replace the circuit board A.

Shift the slide volume from left to right,

then return to the left.

If the result is correct condition, press

the start/stop button to proceed the

next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

09)

Slide volume

Press the needle up/down button.

If the result is correct condition, press

the start/stop button to proceed the

next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

The foot control symbol appears when

the foot control is attached.

Buzzer sounds when the foot control is

deeply depressed.

Buzzer sounds when the foot control is

relased.

LCD displays “SC 09”.

10)

DC motor

11)

Solenoid

(Applicable for

only model

3160QDC)

12)

Thread cutter

motor,

Thread cutter

button

(Applicable for

only model

3160QDC)

Buzzer sounds at right or left position.

LCD displays “SC 10”.

Machine runs slow, then fast, and the

needle bar stops at its highest position.

LCD displays “SC 11”.

Press the needle up/down position

button to display “on” or “of”(off).

Thread tension disc opens while the

LCD displays “on”.

LCD display “12”.

Thread cutter motor wii be initialized.

Press the thread cutter button.

The thread cutter icon will appear and

blink as long as the thread cutter button

is pressed.

Lower the presser foot.

Press the needle up/down button.

If the result is correct condition, press

the start/stop button to proceed the

next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

Buzzer does not sound.

–REMEDY–

Replace the circuit board A.

The machine motor does not

start.

The motor stops immedi-

ately.

The motor runs unstable.

–REMEDY–

Replace the DC motor.

Replace the circuit board A.

Turn the handwheel toward you to raise

the needle bar at its highest position.

Press the needle up/down button.

If the result is correct condition, press

the start/stop button to proceed the

next step.

If the result is defective condition, press

the reverse stitch button to proceed the

next step.

The thread tension disc does

not open.

–REMEDY–

Replace the solenoid

Replace the circuit board A.

The thread cutter motor does

not work.

Thread cutter symbol does

not appear when the thread

cutter button is pressed.

Thread cutter symbol

appears when the thread

cutter button is not pressed.

–REMEDY–

Replace the thread cutter

motor.

Replace the thread cutter

switch.

Replace the circuit board A.

Self-diagnostic Test