LX and LT Low NOx Pool/Spa Heater

Page 39

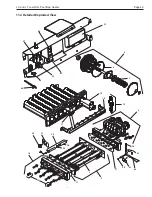

These procedures require a Volt-Ohm

meter with a minimum 0-250VAC voltage range,

and 1-1000 Ohm resistance range. Figure 39

shows the power and control circuits and where

to take measurements. Location numbers in

circles have been added, and will be referenced

in the following sections.

Where test points are shown at circuit board

connectors, the probe of the meter can be carefully

pushed into the connector along side of the wire at the

connection to be measured.

The electrical power supply can be checked with

the heater not set to fire. All other procedures need to

be checked with power correctly supplied to the

heater, all external devices set so that the heater is

allowed to fire and the heater's thermostat set so that

there is a call for heat.

As stated at the beginning of the manual, some of

these procedures are hazardous. Only a qualified

service technician should service the heater.

10.5.1 Electrical Power Supply

The electrical components of the LX and LT

Low NOx pool heaters are designed to operate with

supply voltage ranging from 98V to 126V at 60 Hz if

connected to a nominal 115 volt power supply, or 196V

to 253V at 60 Hz if connected to a nominal 230 volt

power supply. Measure supply voltage at the power

supply leads where they enter the heater (identified as

points A, B and C on the wiring diagram in Figure 39.).

Use the voltages in Table 12 to verify that the correct

voltage is supplied to the heater.

If no voltage is present, correct this external

power supply problem to the heater. Circuit breakers,

time clock settings or similar devices may be the

problem. Voltage outside of the above ranges may be

due to poor wiring, poor connections, other loads such

as air conditioning compressors or to an electric utility

company problem. Arrange for correction of the

voltage as appropriate.

When you are sure that the voltage supplied to

the heater is correct, check the voltage being supplied

to the transformer by the power supply circuit board.

This can be done by measuring the voltage between

the wires of the four-pin connector on the power

supply circuit board. These points are designated as

test points D, E, F, and G on Figure 39. The voltages

measured between any two of these four points will be

determined by the voltage supplied to the transformer

(see Table 13 for expected voltages).

If the voltages measured do not fall within the

limits shown in Table 13, then there is a problem with

the power supply circuit board and the board must be

replaced.

10.5.2 Controller

The controller must be operational in order to

check the control circuits of the heater.

10.5.3 Control Circuit Troubleshooting

The heater controls are arranged in several 24V

60Hz circuits with some operating and safety controls

arranged in series circuits.

Troubleshooting is done by probing for voltage

between the common and various points in the circuit

to determine which component is preventing operation.

Check points are indicated on Figure 39. The black

lead of the meter should be attached to the common

tap on the secondary side of the transformer and may

be left there throughout most of the procedure.

The recommended procedure steps through each

circuit in a sequential way, and each section assumes

that components from all previous sections have been

tested and are operational. However, verifying voltage

at any of the numbered points in that circuit confirms

that all prior components of the circuit are operational.

Table 12. Supply Voltage Measurements

1.

Point A is the ground connection on the heater.

2.

Point B is the location at which the red power lead enters the

power circuit board.

3.

Point C is the location at which the black power lead enters the

power circuit board.

1.

Point D is the location at which the white wire with the black

trace enters the 4 pin connector.

2.

Point E is the location at which the white wire with the red trace

enters the 4 pin connector.

3.

Point F is the location at which the red wire enters the 4 pin

connector.

4.

Point G is the location at which the black wire enters the 4 pin

connector.

Table 13. Voltage Supplied To Transformer

MEASURE

EXPECTED

EXPECTED

BETWEEN

VOLTAGE WITH

VOLTAGE WITH

THESE

230V SUPPLY

115V SUPPLY

POINTS

D and E

0

98 - 126 Volts

D and F

98 - 126 Volts

98 - 126 Volts

D and G

98 - 126 Volts

0

E and F

98 - 126 Volts

0

E and G

98 - 126 Volts

98 - 126 Volts

F and G

196 - 253 Volts

98 - 126 Volts

MEASURE

EXPECTED

EXPECTED

BETWEEN

VOLTAGE WITH

VOLTAGE WITH

THESE

230V SUPPLY

115V SUPPLY

POINTS

A and B

98 - 126 Volts

0

A and C

98 - 126 Volts

98 - 126 Volts

B and C

196 - 253 Volts

98 - 126 Volts