10

Operations/Maintenance

DANGER: BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE HEADER TRANSPORT.

Before the Header Transport is Put into Service:

•

Has the Slow-Moving Vehicle sign been properly positioned at the rear of the header transport?

•

Have all danger, warning, caution and important signs on the equipment been read and understood? If employees or others use or

are near this equipment, make sure that they also have read and understood all danger, warning, caution and

important signs on the equipment and have also read the operator’s manual.

•

Are all braces, bolts, nuts, studs and lug nuts properly fastened?

•

Has the header transport been properly fastened to the towing unit? Use a good quality hitch pin with clip and safety chains.

•

Are the rear amber extremity lights properly positioned? Extend lights within 16” of the left and right extremities of the header.

Safety Chain User Instructions

•

Secure the safety chain by looping it around the tongue support located on the underside of the hitch tongue and connect to the

towing machine’s attaching bar.

•

Do not allow more slack than necessary for articulation.

•

Do not use an intermediate support as the attaching point.

•

Store the safety chain by securing it around the tongue.

•

Replace the safety chain if one or more links or end fittings are broken, stretched or otherwise damaged or deformed.

WARNING: Check safety chains for broken, stretched or damaged link or end fittings. Replace chains if found to be

damaged. Do not weld safety chains.

Operating Instructions/Maintenance

•

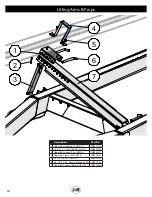

Adjust the brackets on the header transport to best fit your make and model header.

Note: When mounting the header, NEVER position yourself under or near the header. Securely fasten the header to the

header transport.

•

Do not exceed the load and size limits of the unit.

•

Keep the tires properly inflated. Both under inflation and over inflation can greatly reduce tire life. Inflate 235-85 R16 tires to 80 psi.

•

Inspect bracing and welds periodically and repair immediately, if needed. Failure to repair could cause extensive damage and

greatly reduce the life of the unit.

•

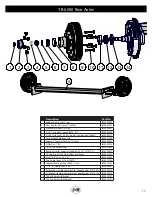

Repack the bearings in the hub assembly once a year or as needed. Use a good quality LS EP2 severe duty, high shock load, lithium-

based grease.

•

Grease the ball using the zerk on the front gooseneck assembly every 8 hours or as needed.

•

Check the wheel nuts often and keep them properly tightened.

Braking System Requirements

•

Stopping distance increases with speed and weight of towed loads and on slopes. Towed loads with or without brakes that are too

heavy for the tractor or are towed too fast can cause loss of control. Consider the total weight of the equipment and its load.

Note: Observe these recommended maximum road speeds, or local speed limits which may be lower.

•

If towed equipment does not have brakes, do not travel more than 20 mph (32 km/h) and do not tow loads more than 1.5 times the

tractor weight.

•

If towed equipment does have brakes, do not travel more than 25 mph (40 km/h) and do not tow loads more than 4.5 times the trac-

tor weight.

•

Ensure the load does not exceed the recommended weight ratio. Use additional caution when towing loads under adverse surface

conditions, when turning, and on inclines.

DANGER: Tow loads safely.

Summary of Contents for Trail-Blazer TB-6000

Page 2: ......