Issue: 01.07.2020

Page 13

Installation

Pressure testing

Both the indoor and outdoor units have been pressure tested in the factory prior to dispatch and contain a

holding charge of oxygen free nitrogen.

Once the pipework installation is complete, it should be pressure tested prior to evacuation to test for leaks.

A pressure leak test should be carried out using oxygen free nitrogen (OFN). NEVER USE OXYGEN FOR PRESSURE TESTING

SYSTEMS. A calibrated nitrogen pressure regulator must always be used. Before starting any pressure testing, ensure the area

surrounding the system is safe, inform relevant personnel and fit warning signs indicating high pressure testing. Also, use correct

PPE as required.

Listen for any possible leaks and check all joints with bubble spray. If any leaks are discovered, release pressure slowly from

system until empty, repair leak and then restart pressure testing procedure. Never attempt to repair a leak on a pressurized

system.

A strength test should also be incorporated according to local regulations.

Once testing has been completed satisfactorily, release the pressure from the system gradually and safely to external

atmosphere.

Important Note:

Do not open the service valves on the condensing unit until pressure testing procedures have been

carried out.

Summary of Contents for Cellar Plus 70-S1

Page 1: ...CELLAR PLUS CELLAR COOLER RANGE ISSUE 01 07 2020 CELLAR COOLER RANGE TECHNICAL MANUAL...

Page 8: ...Issue 01 07 2020 Page 8 Installation Quick Guide Piping Single System Twin System...

Page 24: ...Issue 01 07 2020 Page 24 Drawings Dimensional drawings Indoor Unit 80E...

Page 26: ...Issue 01 07 2020 Page 26 Drawings Dimensional drawings Outdoor Units BSCU 40 M1 M3...

Page 33: ...Issue 01 07 2020 Page 33 Certification...

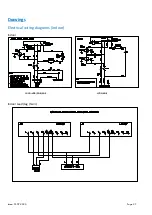

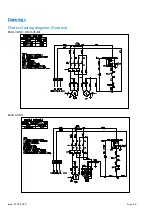

Page 34: ...Issue 01 07 2020 Page 34 THIS PAGE IS LEFT BLANK INTENTIONALLY...