26

www.ndtJames.com

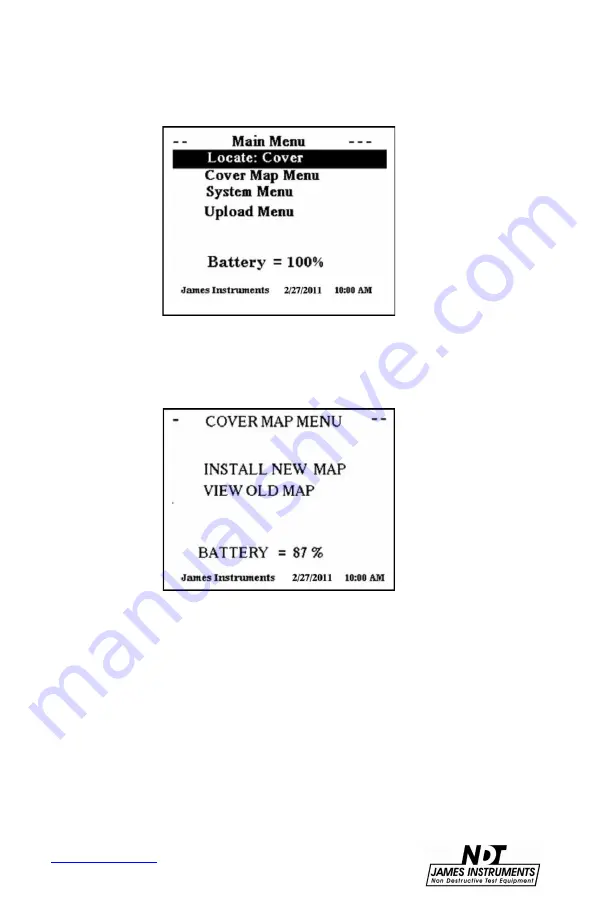

Step 1

: Press the escape key on the front panel to get to the Main

Menu screen.

Figure 23: Cover Function

Step 2

: Navigate the highlighted cursor using the up or down arrow

keys to

COVER MAP MENU

option and press Enter.

Figure 24: Cover Map Menu